Get $500 in credit on your first machine when you purchase in the month of February. Shop Products

streamline your filling process and boost productivity

GET $500 OFF ANY MACHINE!

Delivers reliable, high-quality, and professional filling solutions to businesses and manufacturers, all from one trusted source. Our commitment to safety ensures peace of mind for our customers.

Trusted by Organizations Nationwide

fills 1gram → 5 lBS.

Servo Drive or Clutch Brake Motor.

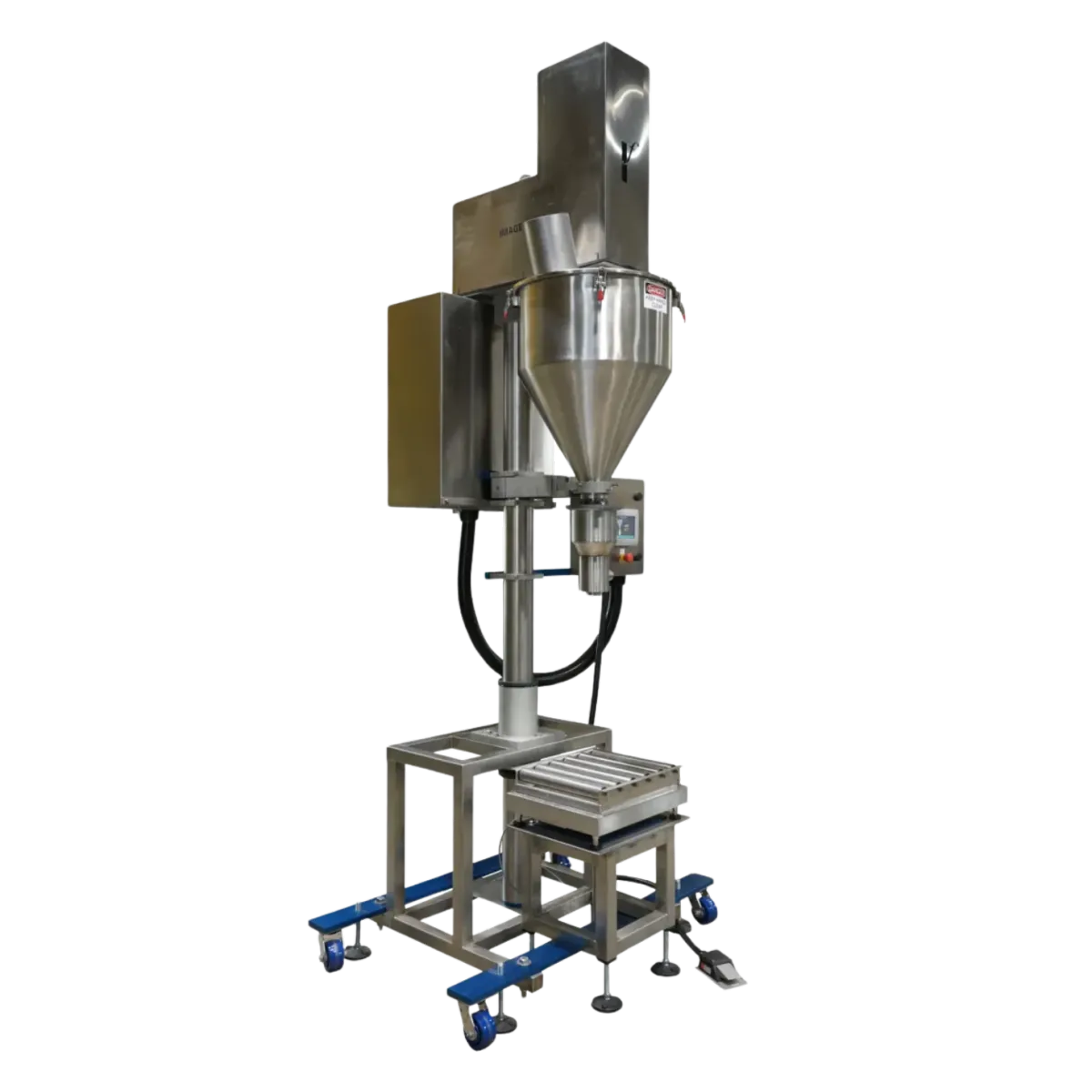

Image 4K

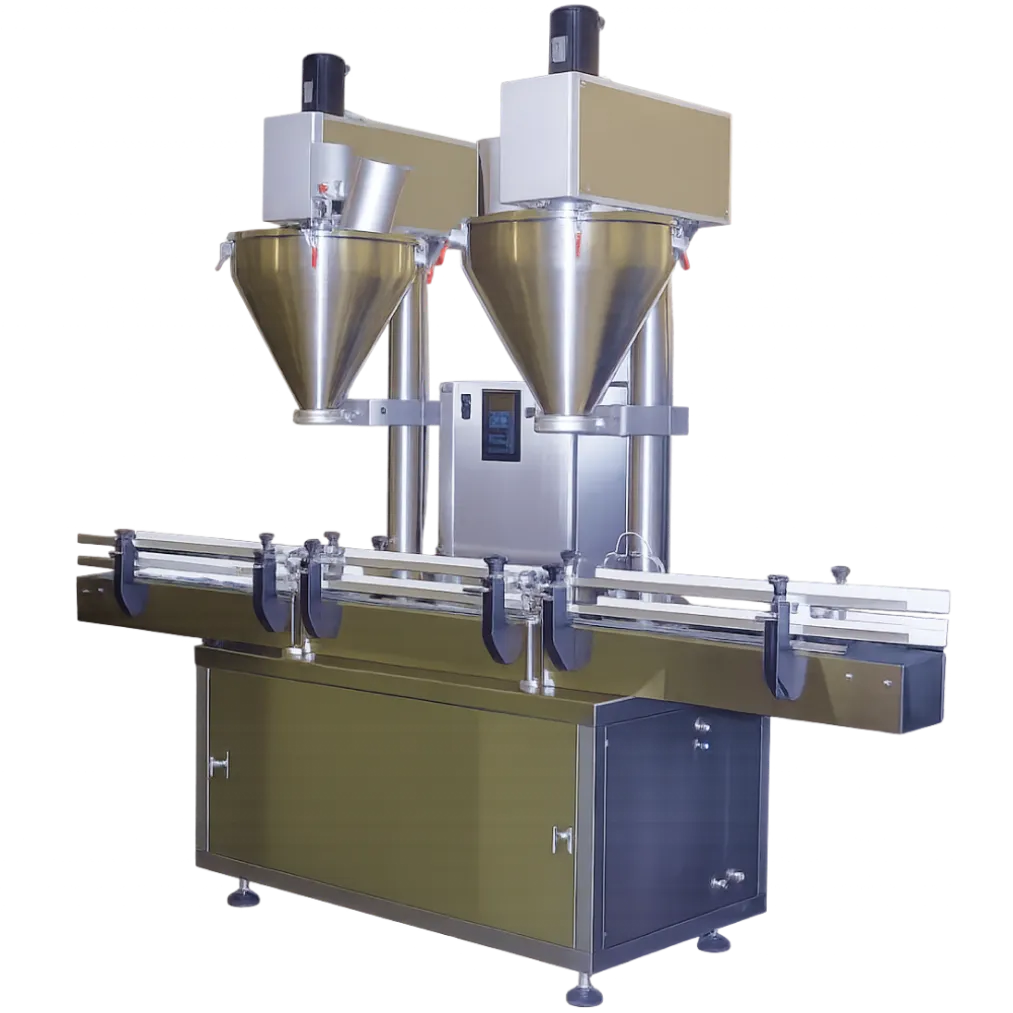

fills 1gram → 5 lBS.

Servo Drive or Clutch Brake Motor.

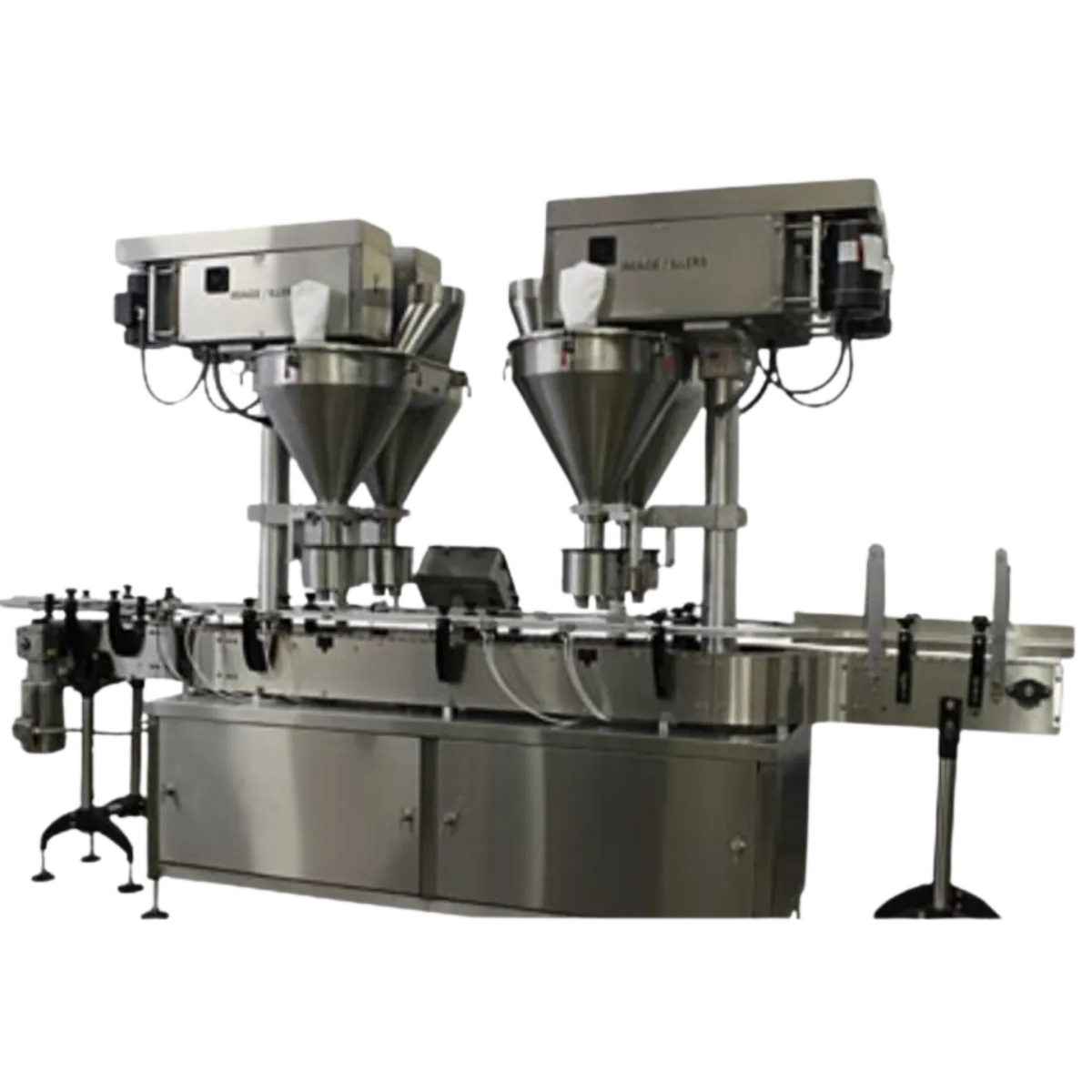

2 - 4 heads & conveyor.

Image 7K

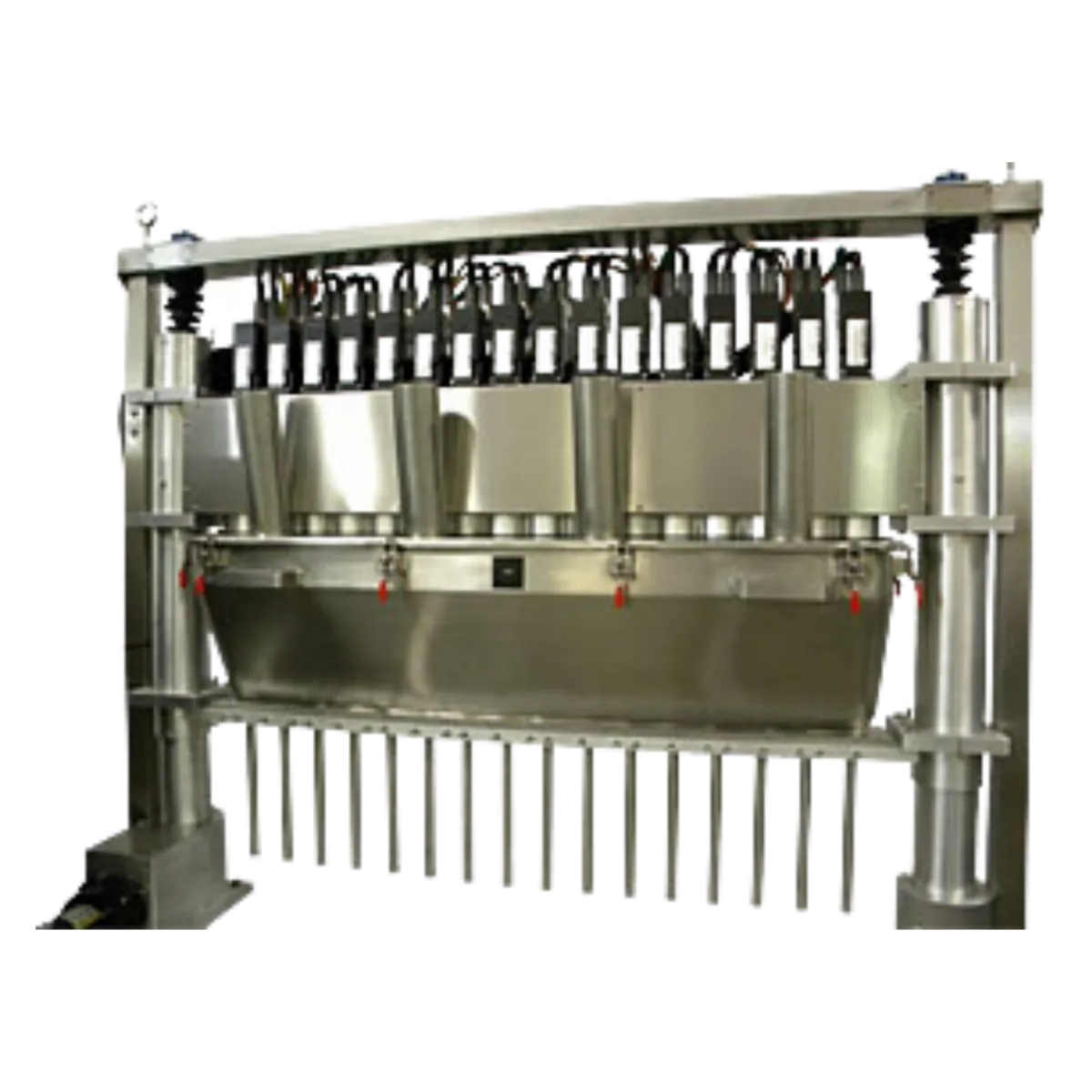

Fills 2-8 packets at once

Multi Head Filler

Perfect Solution

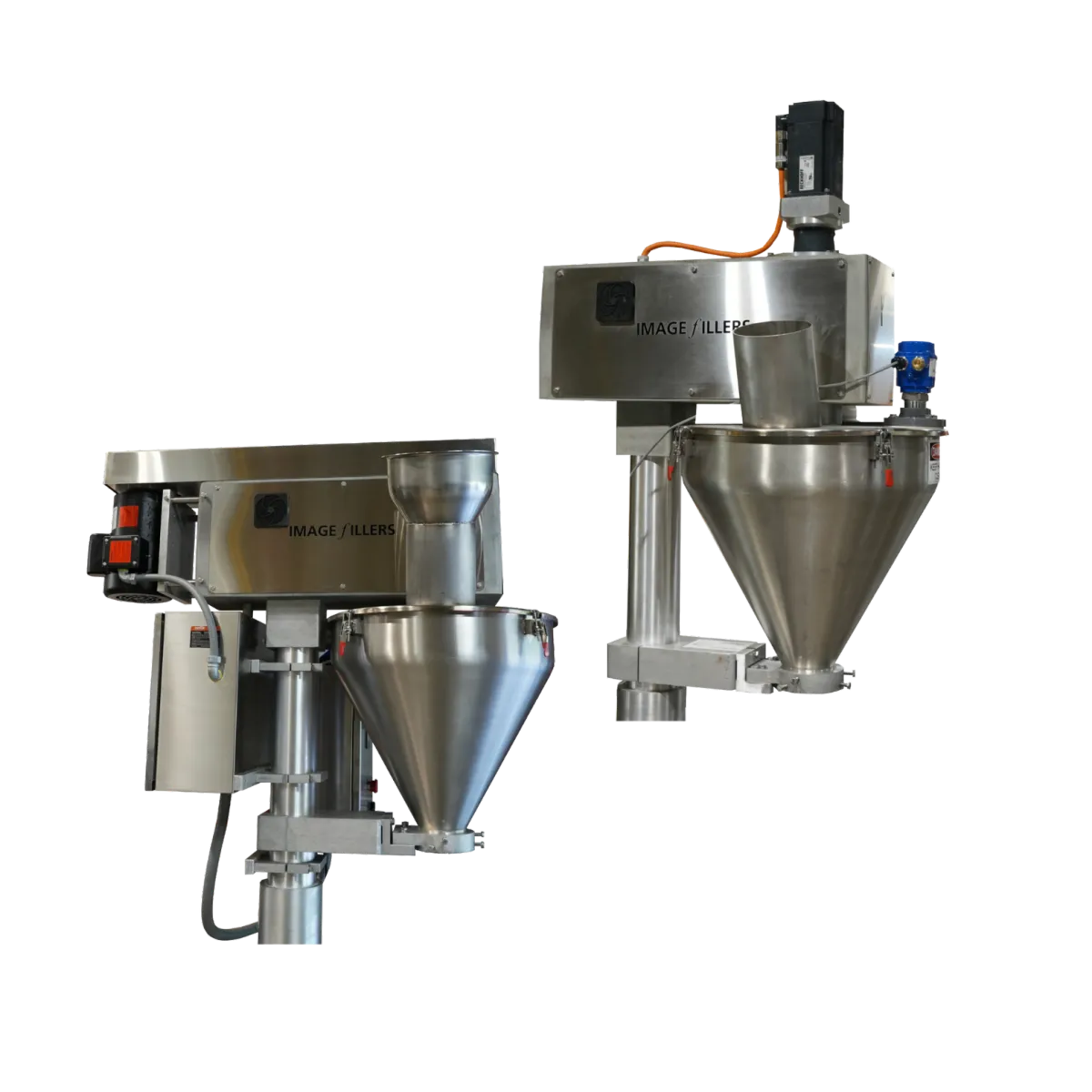

Free standing auger fills 1gram → 5 lBS.

Perfect Solution

Free standing auger fills 1gram → 5 lBS.

Tooling & Parts for your auger filler machine.

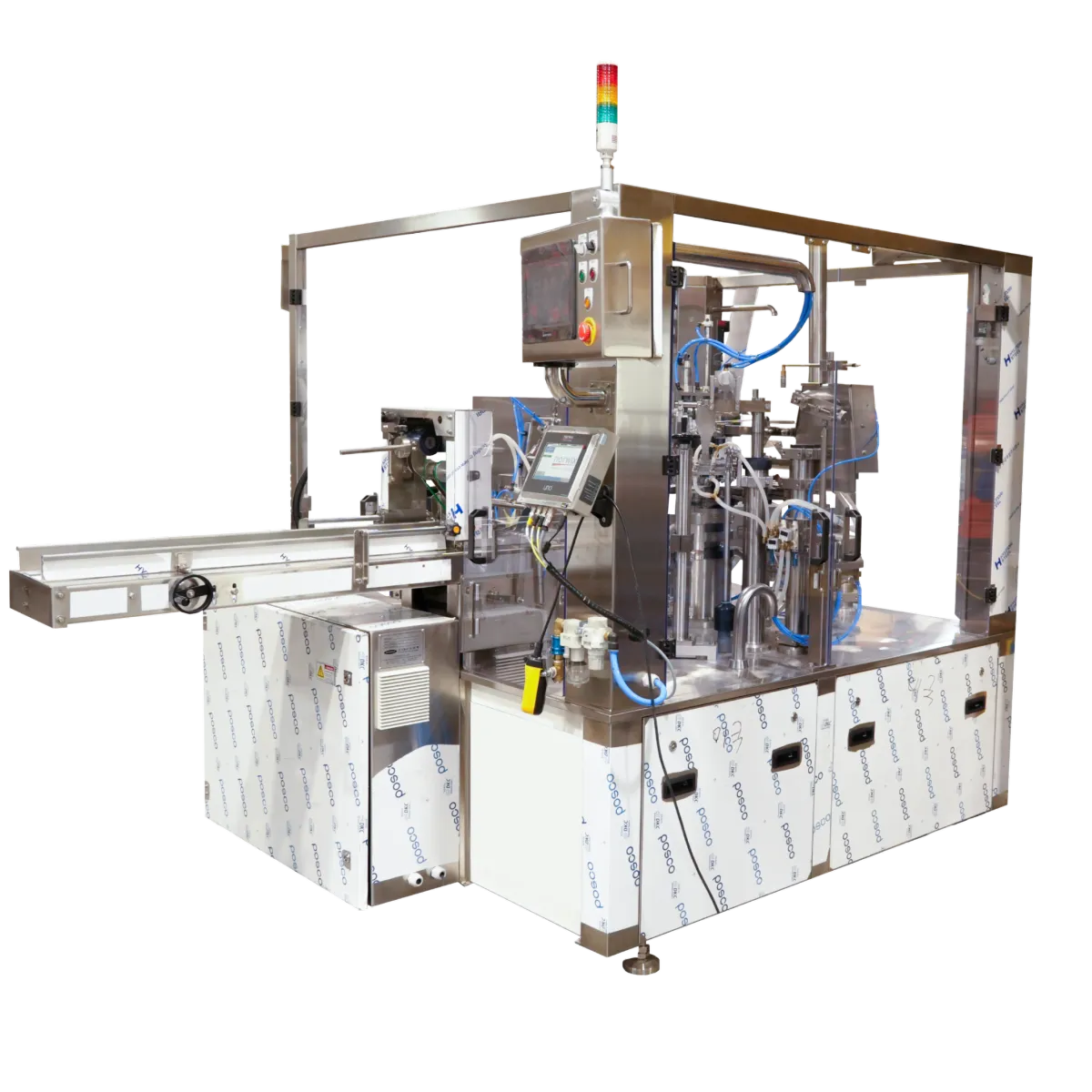

filling & Packaging

Fully Integrated Packaging Line

Our Fully Integrated Packaging Line offers a complete system that orients, labels, fills, caps, inkjet codes, and collects your products. It can handle powders, viscous products, and liquids, and is fully modular, allowing for additional equipment to be added to the line. Streamline your packaging process with our state-of-the-art technology and cost-effective solution. Contact us to learn more.

Playlists

100+

Clients

100%

5 Star Reviews

200+

Jobs Completed

The latest.

Take a look at what's new, right now.

Top-rated supplier of auger filling machines.

Free Shipping + 2 Free Accessories

Satisfied Customers Speak for Us

Michelle Torres

Image fillers provides excellent products, superior service and offer pricing that is in line with other companies offering the same products. We are always confident when placing an image filler that the equipment will perform as promised.

Jerry Carter

I have purchased several of Image Fillers machines over the years and have been very happy with the machines and the customer service I received from Mike and his team.

Ed Walinski

Mike is a very customer service oriented Sales Manager. I've worked with him for 5-6 years and experienced the same results each time.

Kevin Weber

Mike and his team have solid working knowledge of applications where the equipment is going to be placed. They are responsive to requests and a fair and honest company to work with.

LEARN MORE ABOUT OUR PRODUCTS

↓ WATCH THIS QUICK VIDEO TO LEARN MORE ABOUT OUR PROCESS! ↓

[Customer Name]

[“If you could only show your visitor one testimonial from the past...who would it be? Use this section to present a brief quote from your biggest, most compelling success story!”]

[Customer Name]

[“If you could only show your visitor one testimonial from the past...who would it be? Use this section to present a brief quote from your biggest, most compelling success story!”]

[Customer Name]

[“If you could only show your visitor one testimonial from the past...who would it be? Use this section to present a brief quote from your biggest, most compelling success story!”]

LEARN MORE ABOUT OUR

ROOFING PROCESS!

↓ WATCH THIS QUICK VIDEO TO LEARN MORE ABOUT OUR PROCESS! ↓

Trusted by Organizations Nationwide

Trusted by Organizations Nationwide

September 6, 2024

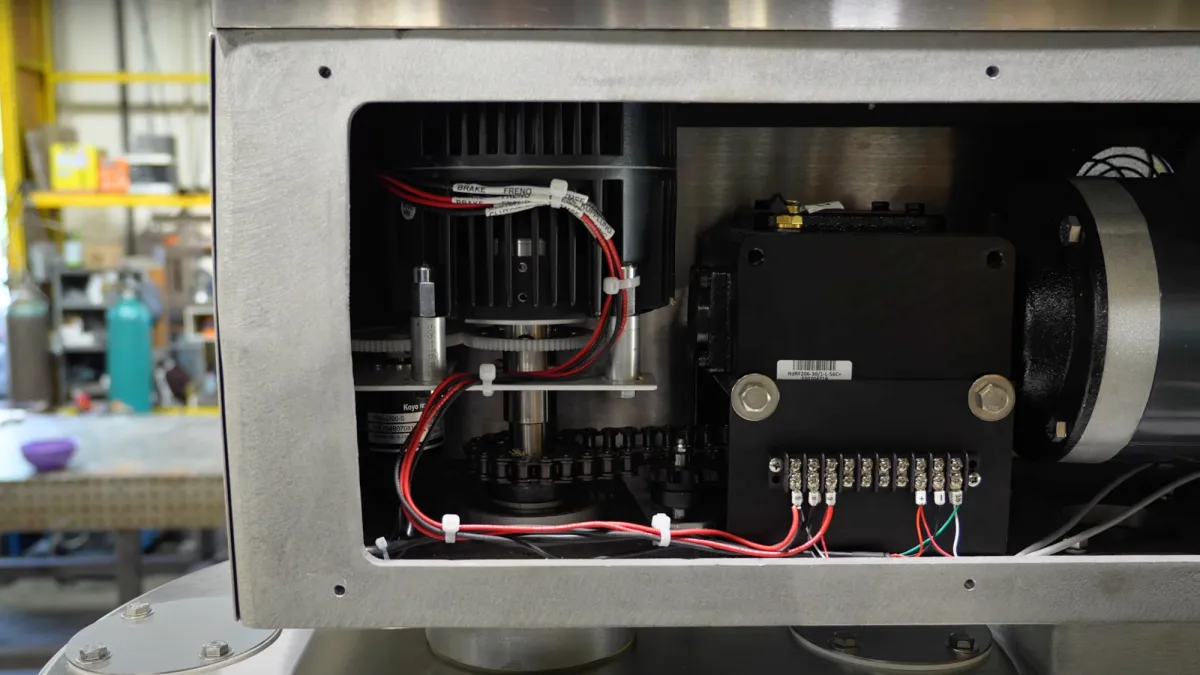

Clutch Brake Motor Replacement

How to remove and reinstall the clutch brake motor in your auger filler

This guide will walk you through the step-by-step process of removing the old clutch brake motor and installing a new one. By following these instructions, you can efficiently handle the process and get your machine back to optimal performance.

Step 1: Remove Side Covers

Begin by removing the side covers of the filling head. Unscrew the 6 bolts on the cover, allowing access to the internal components.

Step 2: Remove Top Cover

Take off the top cover by unscrewing the 2 bolts at the top of the head. This will expose the upper part of the filling mechanism.

Step 3: Remove Auger Shaft

Slide the auger shaft out from the head to free up space for the motor removal.

Step 4: Remove V-Belt

Remove the v-belt from the pulley system to disconnect the motor from the pulley drive.

Step 5: Remove Pulley

Loosen the two Allen bolts on the bottom side of the pulley. With the bolts loosened, use two prying irons to carefully remove the pulley from its position.

Step 6: Remove Clutch Brake Bolts

Unscrew the 4 bolts located on the outside diameter of the top of the clutch brake. These bolts secure the brake to the head of the machine.

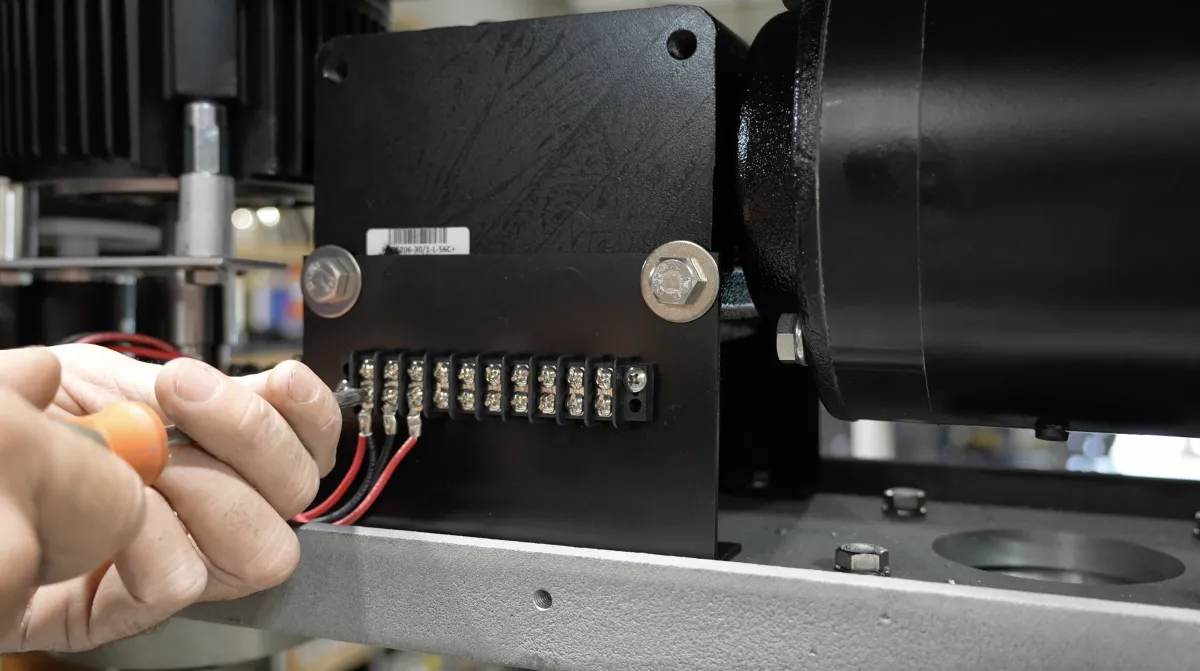

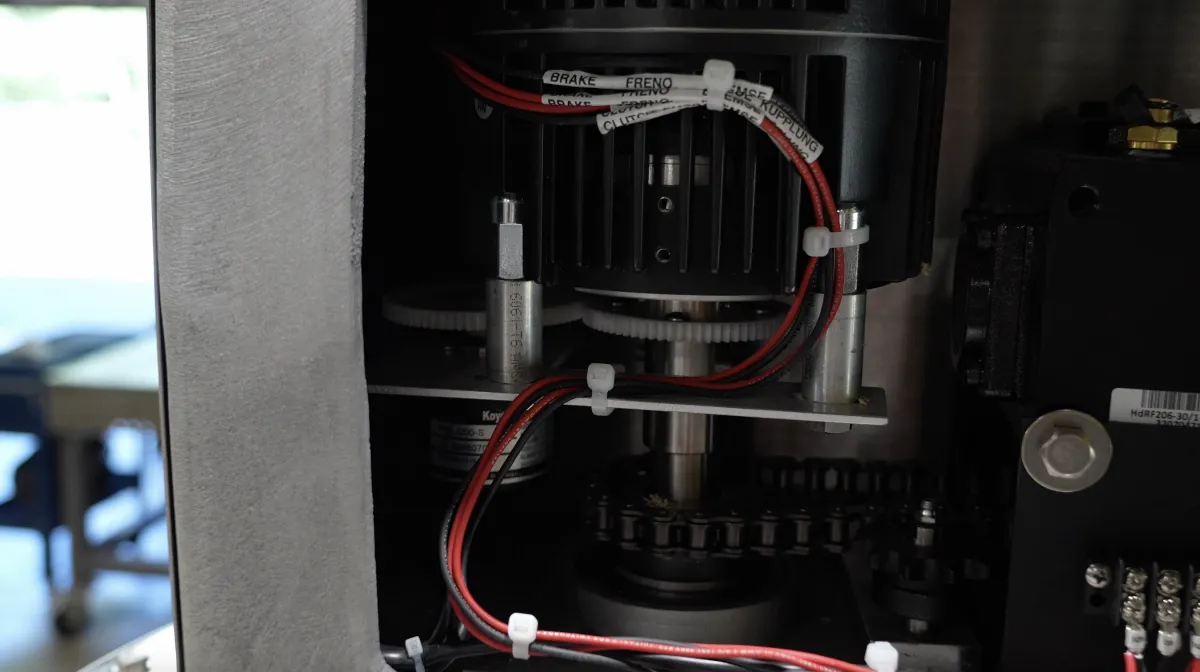

Step 7: Disconnect Clutch Brake Wires

Disconnect the 4 wires connected to the clutch brake at the terminal strip. Make sure to take note of which wires are connected to which section of the strip for later reinstallation.

Step 8: Remove Encoder Bracket

Unscrew the 2 bolts holding the encoder bracket in place. Once removed, carefully lift the bracket, spacers, and encoder. The encoder can remain attached to the bracket during this process.

Step 9: Lift Out Clutch Brake Motor

Once all wires and bolts are removed, lift the clutch brake motor up and out of the filling head.

Step 10: Remove Mounting Bracket

Lastly, remove the mounting bracket attached to the top of the clutch brake by unscrewing the 4 bolts located inside the diameter of the top of the brake.

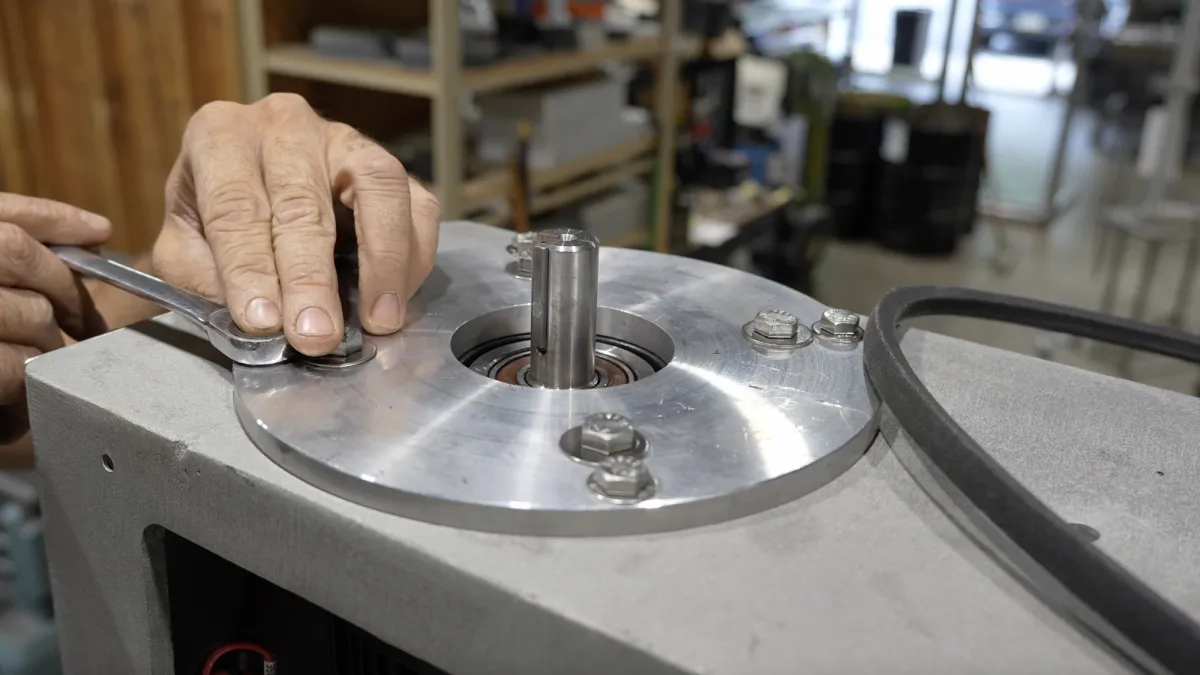

Clutch Brake Motor Installation

Step 1: Step Attach Mounting Bracket to New Clutch Brake

Place the mounting bracket onto the new clutch brake and securely fasten the 4 bolts to the inside diameter of the top of the brake.

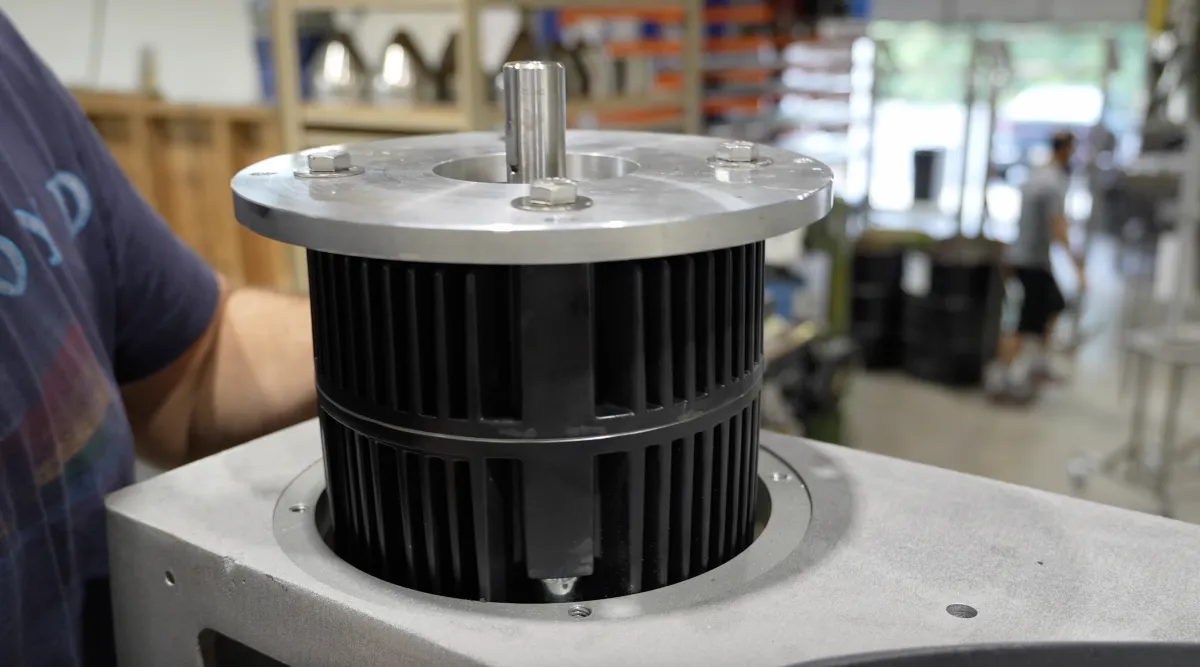

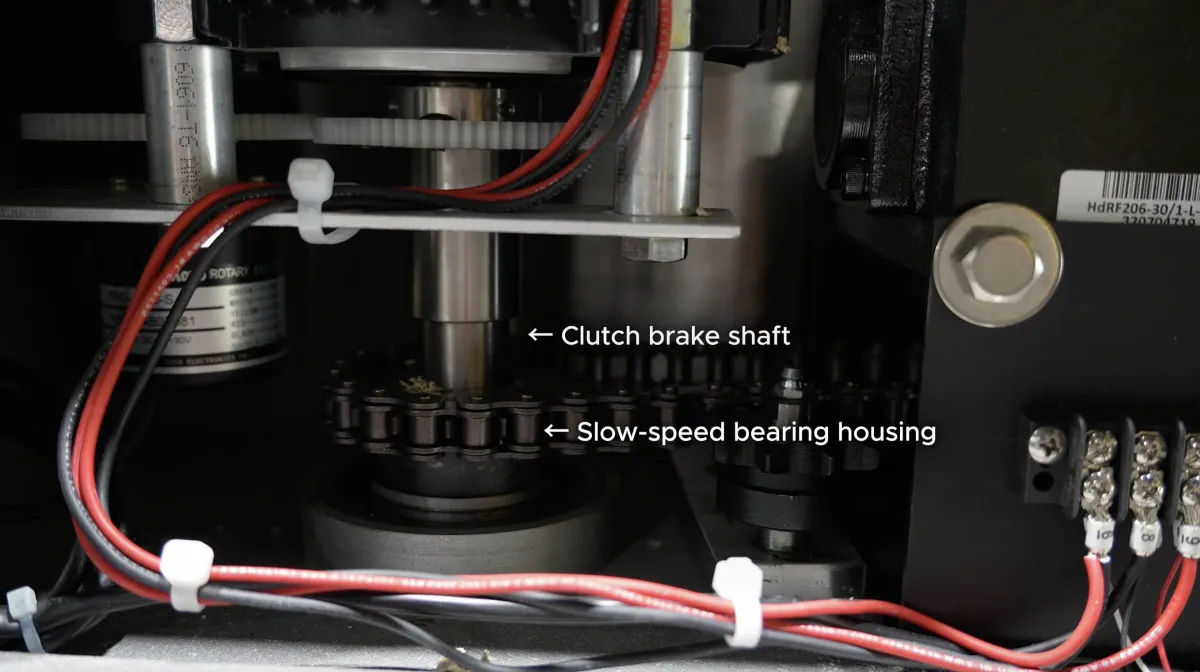

Step 2: Insert New Clutch Brake into Place

Slide the new clutch brake motor into its designated position. Make sure the shaft fits smoothly into the slow-speed bearing housing. Ensure the clutch brake fits snugly onto the head of the machine.

Step 3: Secure the Clutch Brake Bolts

Fasten the 4 bolts into the outside holes on the top of the clutch brake to firmly secure it in place.

Step 4: Reattach the Encoder Bracket

Align the encoder gears properly and screw the 2 bolts back into the bracket at the bottom of the clutch brake. Make sure the gears are snug but not overly tight to prevent unnecessary wear.

Step 5: Reconnect Clutch Brake Wires

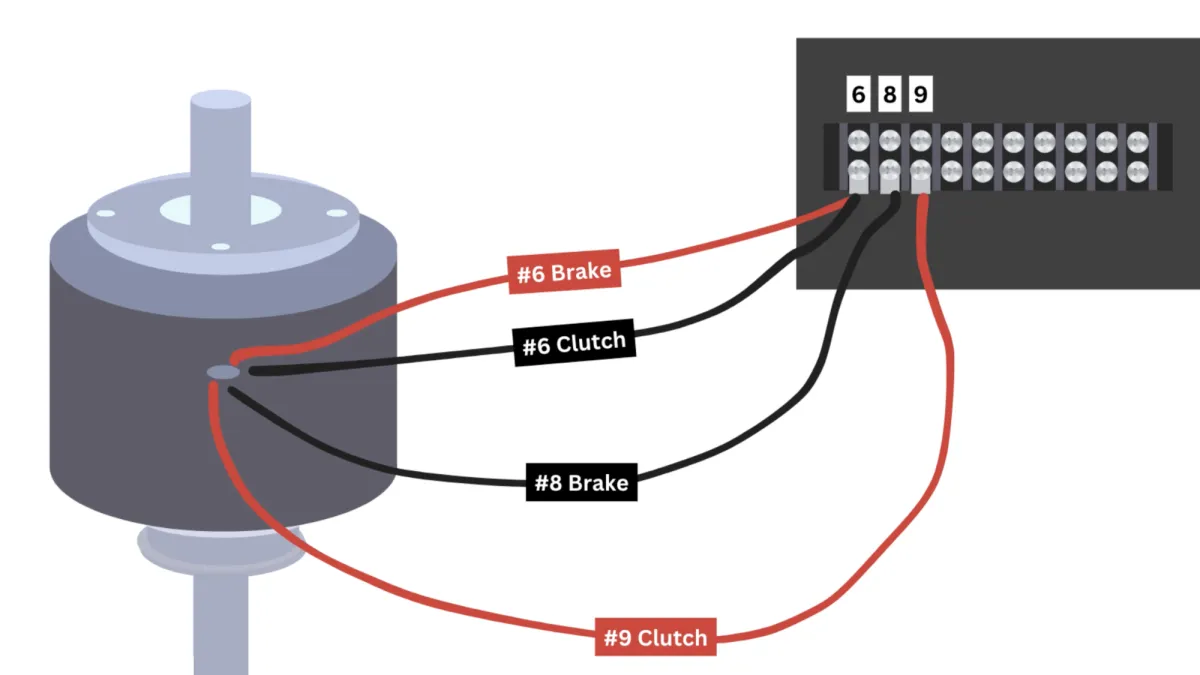

Reconnect the 4 wires to their corresponding sections on the terminal strip. The wires should be labeled "clutch" or "brake," with common connections being:

Red brake wire and black clutch wire to terminal 6

Black brake wire to terminal 8

Red clutch wire to terminal 9

If you are unsure, refer to your earlier notes or contact our team at Imagefillers.com for assistance.

Step 6: Reinstall Pulley

Slide the pulley back onto the shaft and tighten the two Allen bolts on the underside to secure it.

Step 7: Reattach V-Belt

Reinstall the v-belt onto the pulley system, ensuring it is aligned and tensioned correctly.

Step 8: Reinstall Top Cover

Secure the top cover back in place by tightening the 2 bolts at the top of the head.

Step 8: Reattach Side Covers

Finally, reinstall the side covers by fastening the 6 bolts removed at the start of the process.

Get a replacement

Get a new clutch brake motor here:

Insights in your inbox

Sign up for updates on products, tips, and more

Contact

Hours: 9 AM - 5 PM

735 Fox Chase Rd # 111, Coatesville, PA 19320

(610) 466-1440

To purchase a machine, call (610) 466-1440 or email [email protected]

Image Fillers © 2025

Made in the United States