Get $500 in credit on your first machine when you purchase in the month of February. Shop Products

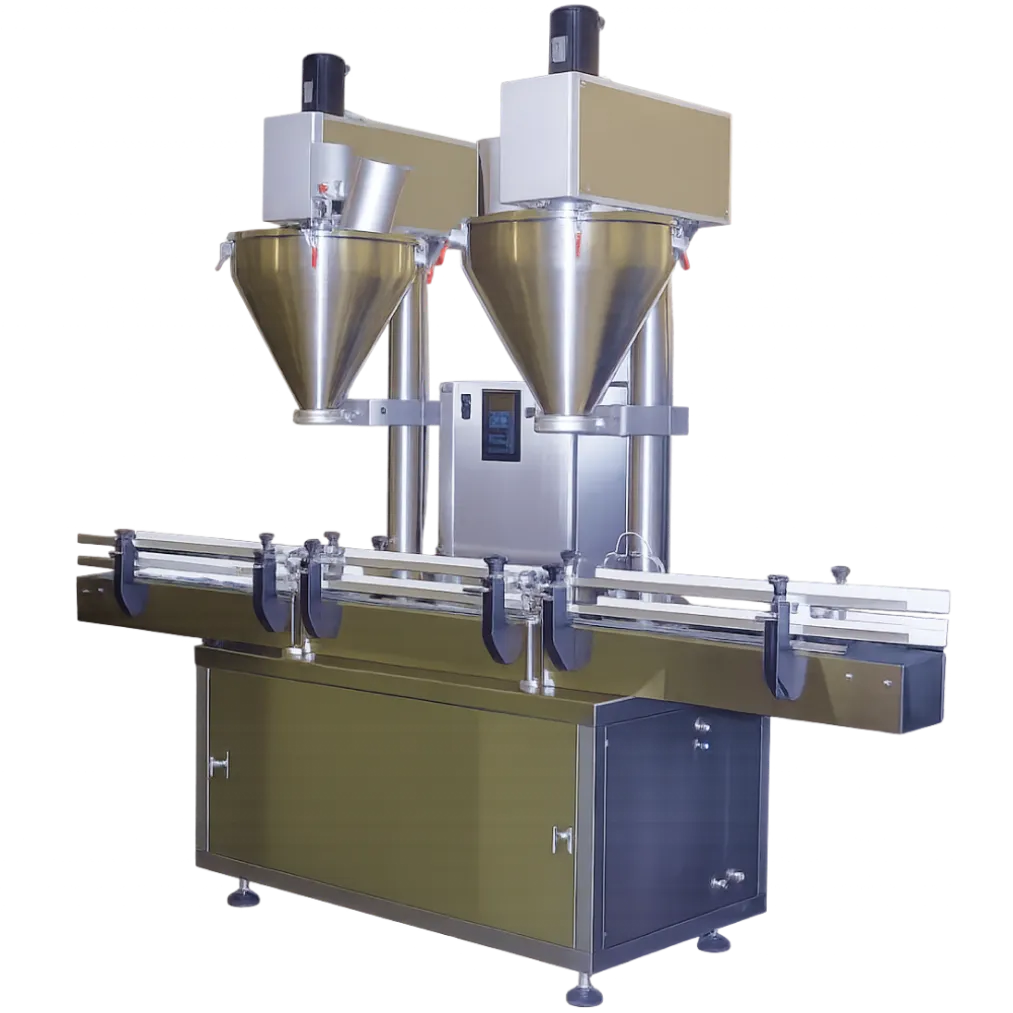

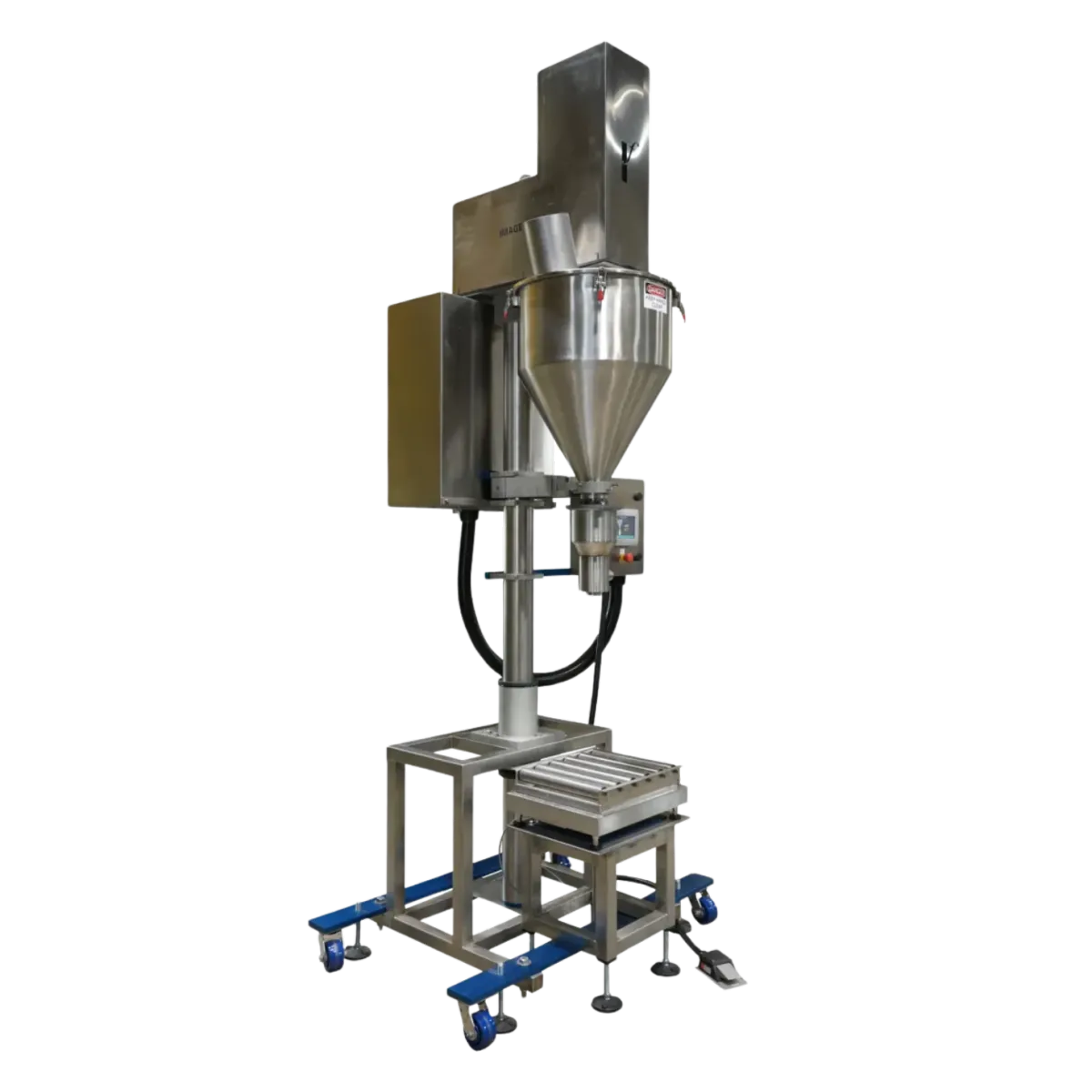

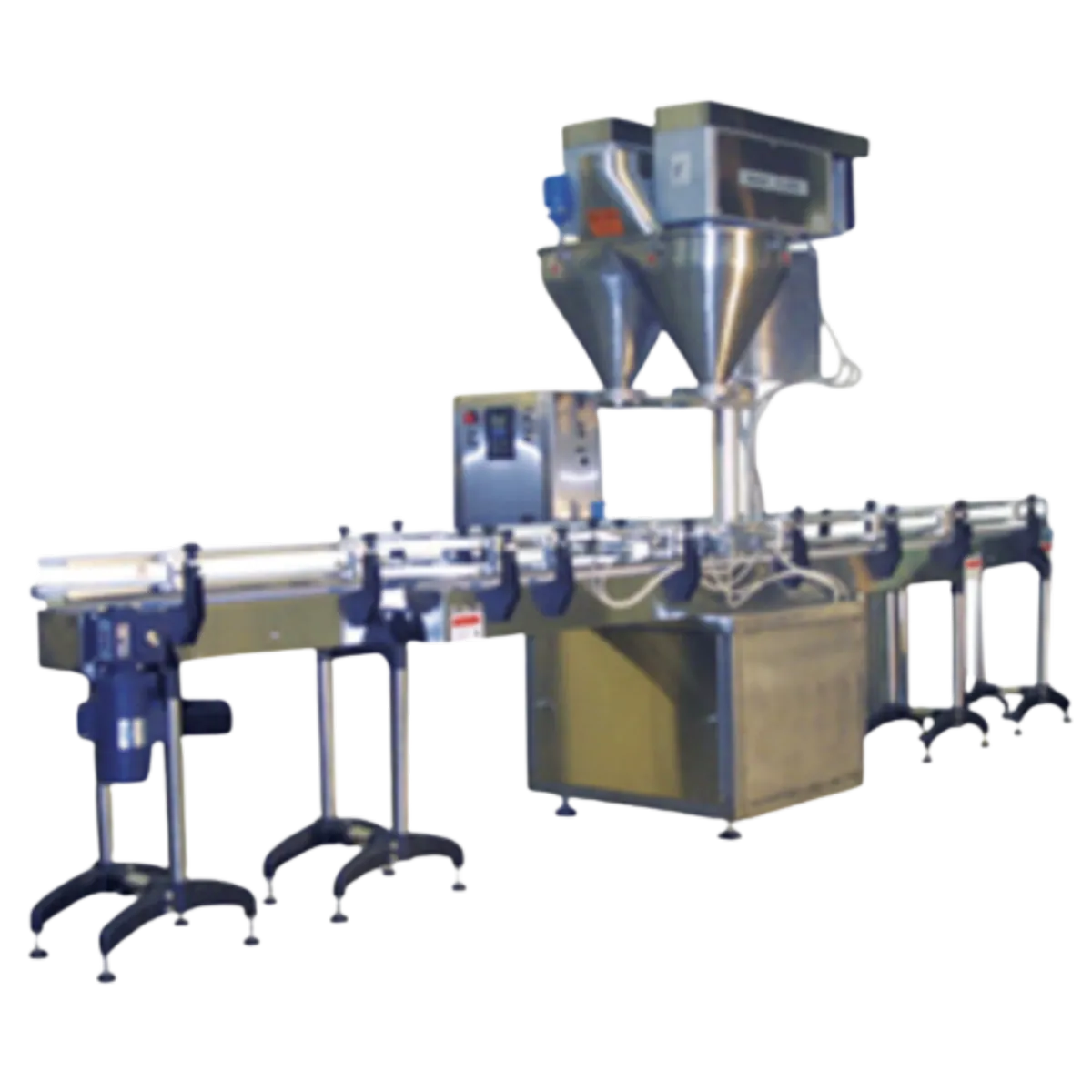

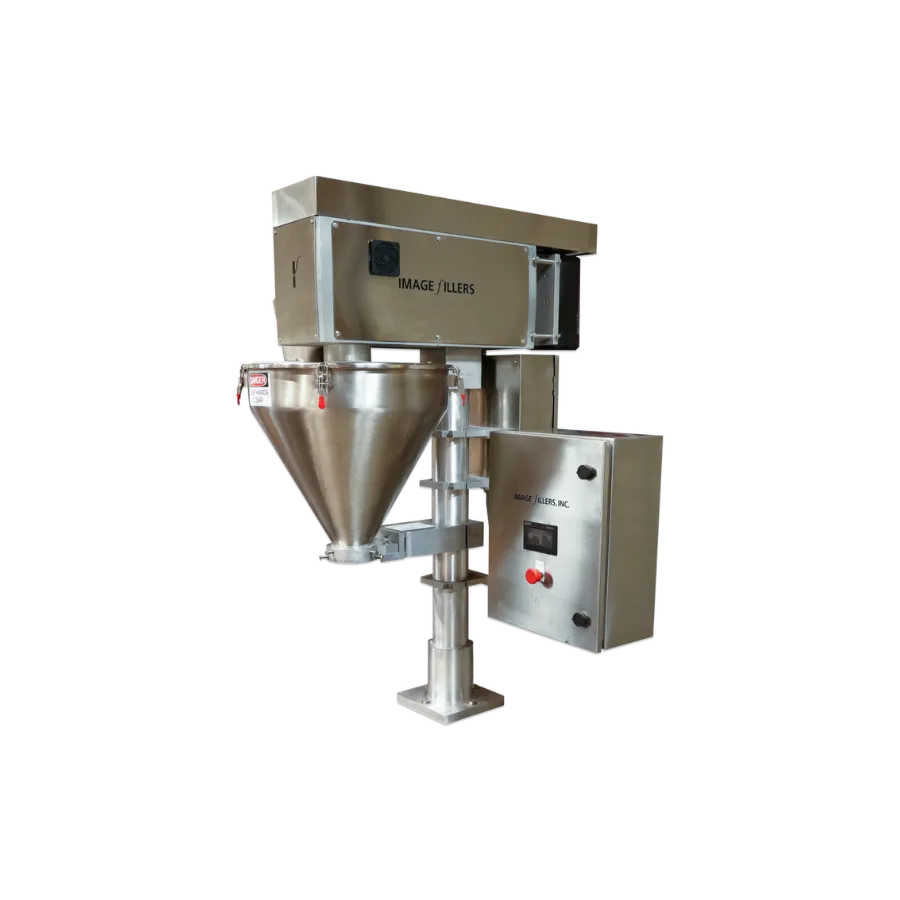

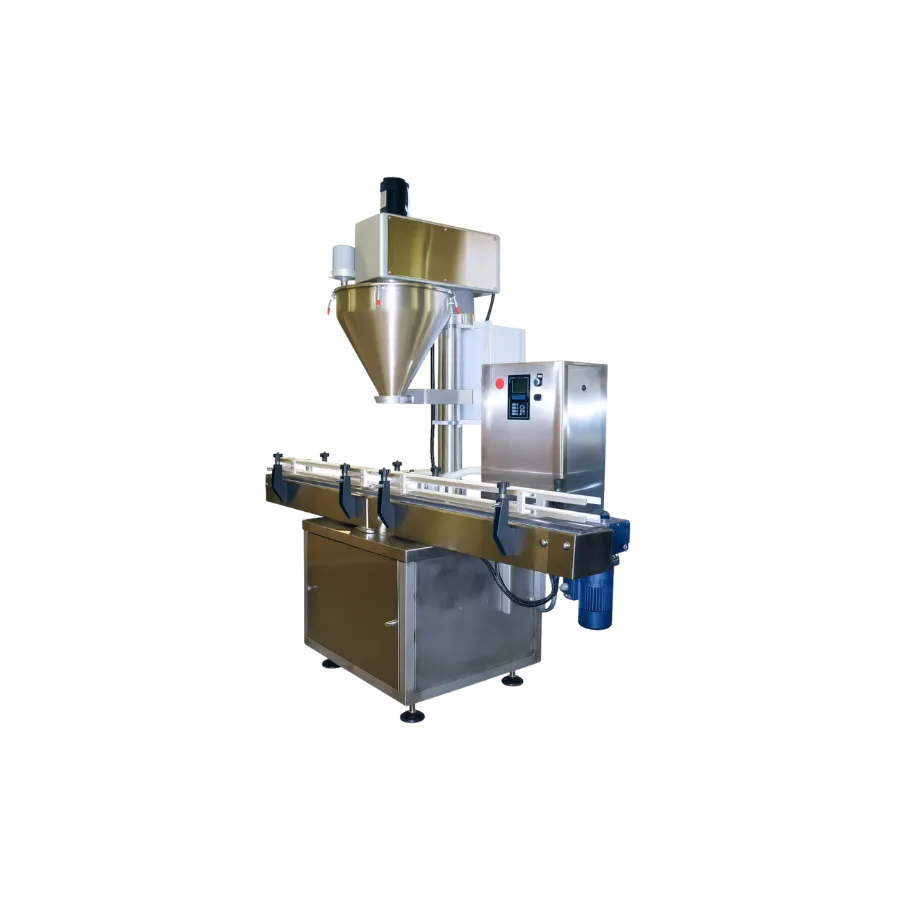

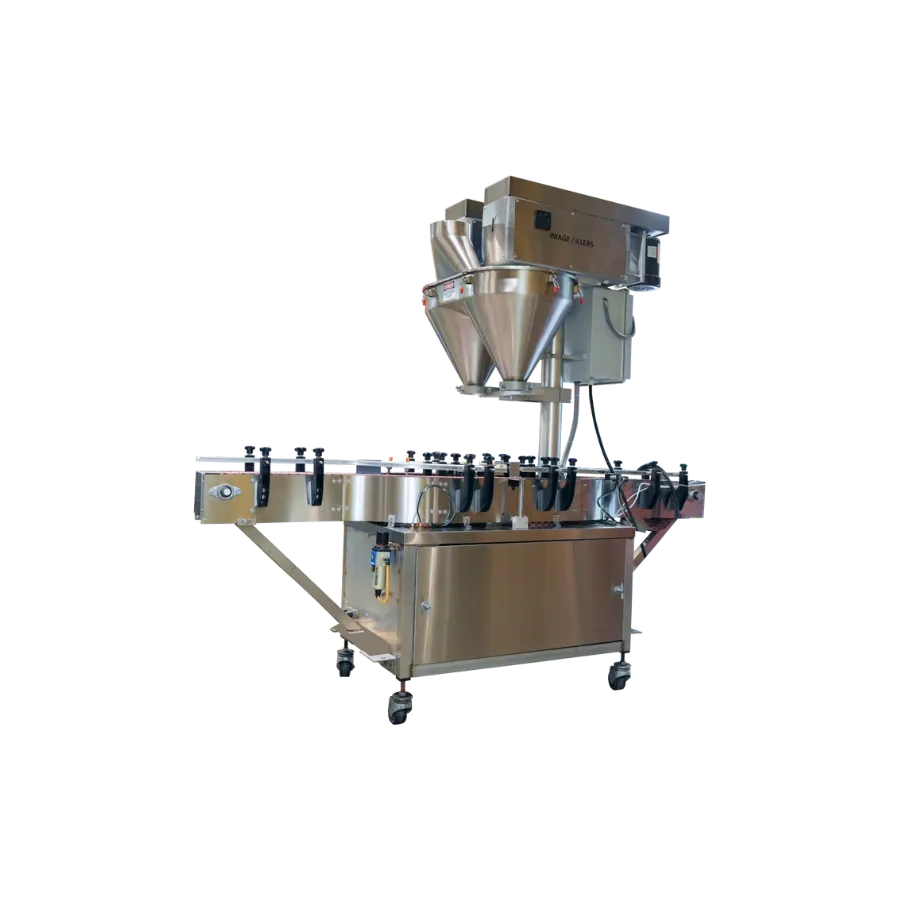

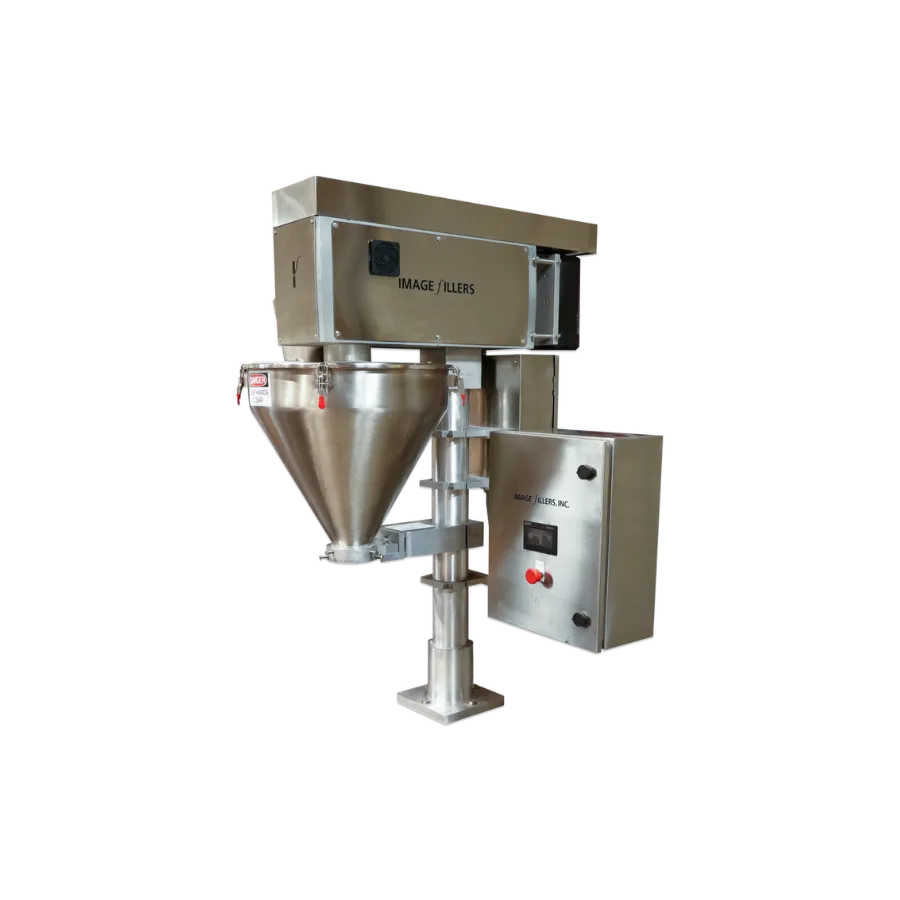

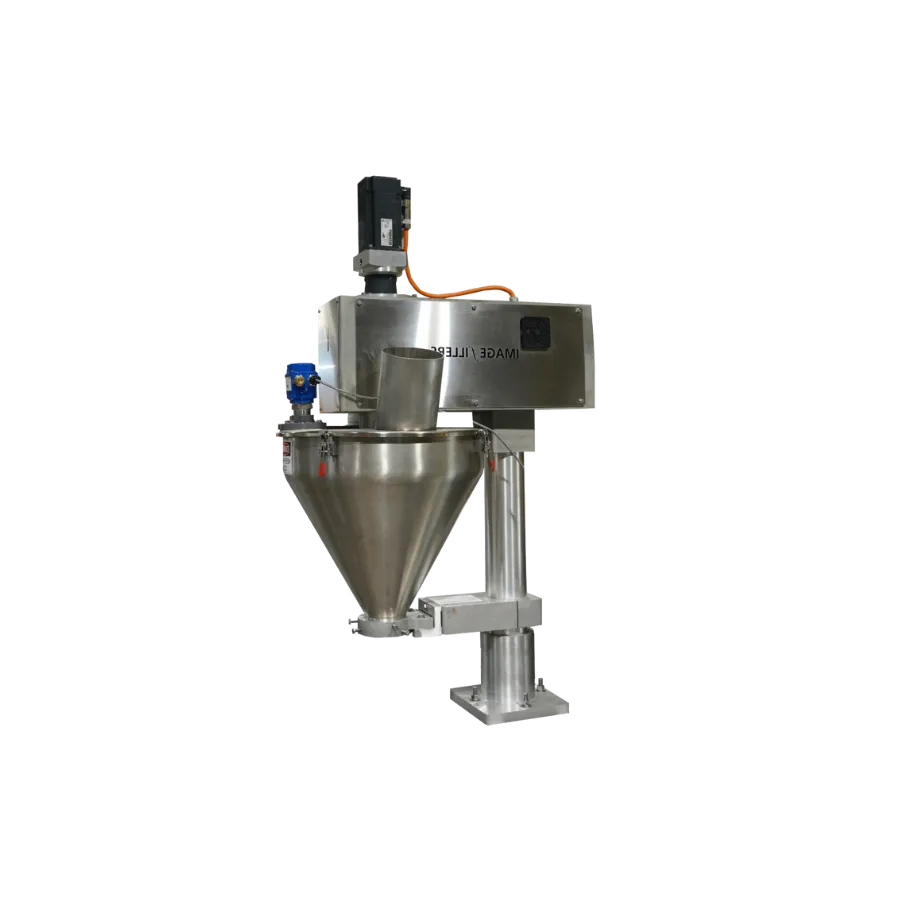

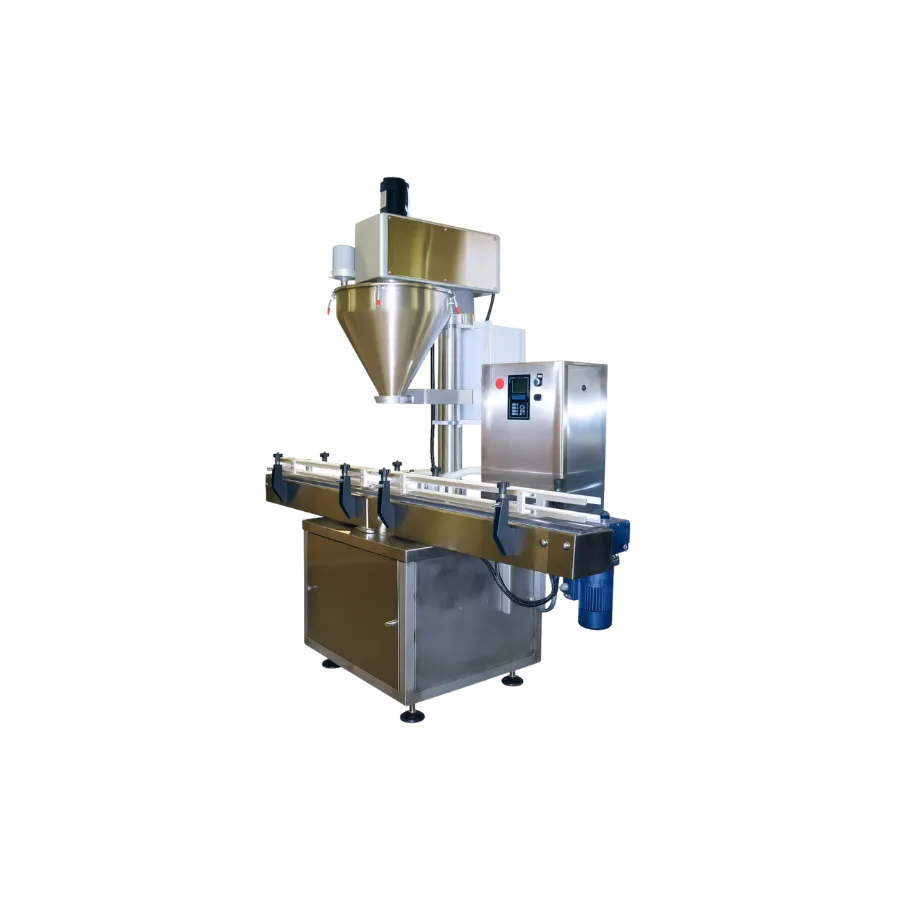

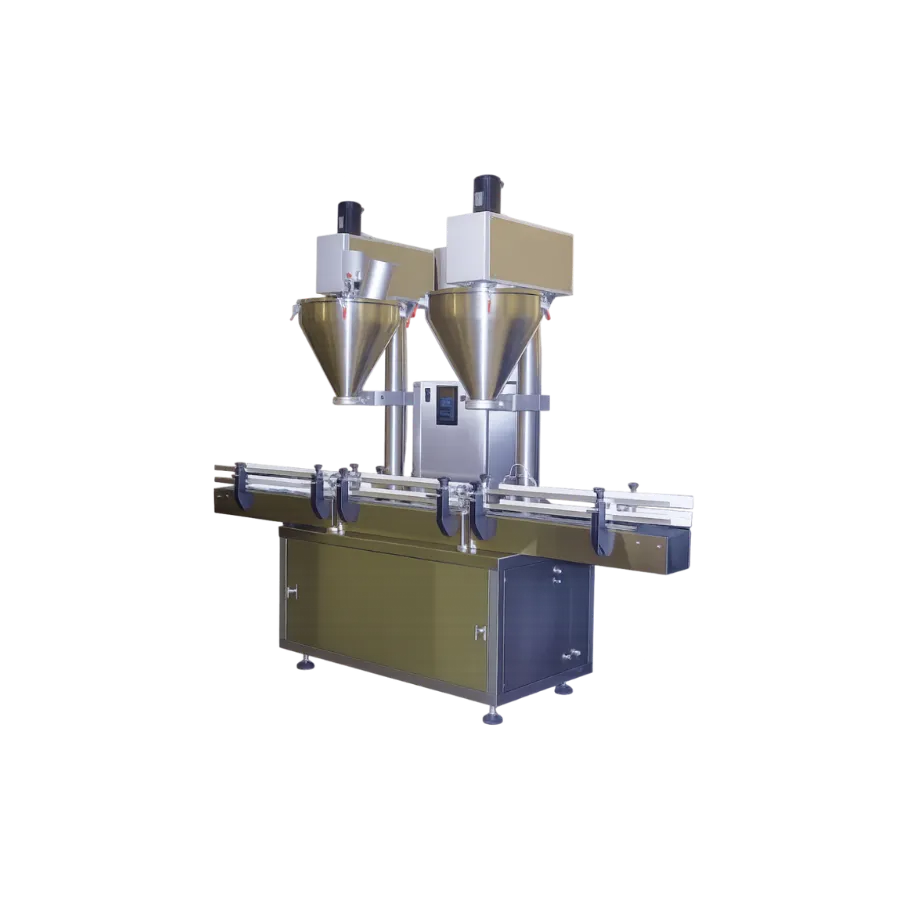

Image 5K

Dual head filler & split lane conveyor

Description

The Image 5K is a high-performance twin-head auger filler with adjustable centers ranging from 9” to 20”. Narrower centers are seamlessly accommodated with a custom-fabricated fill head.

Its advanced conveyor system features a single infeed that efficiently splits into two lanes, enabling simultaneous filling of two containers without any empty units passing to a second station. This design delivers a genuine “double your production” solution, maximizing throughput and efficiency.

Features

• Stainless steel and anodized aluminum build for durability

• Two 16-gallon hoppers with quick release clamps for easy removal

• Clutch brake or servo drive motor

• Motor protection

• Agitation blade (prevents product sticking to hopper)

• Split lane stainless steel indexing conveyor

• Allen Bradley PLC

Optional:

• Pneumatic Lift

• Vibration

• Vibration on conveyor for accurate filling

• 36”, 48”, and 60” diameter unscrambling and accumulation tables (pictured with two 36” tables)

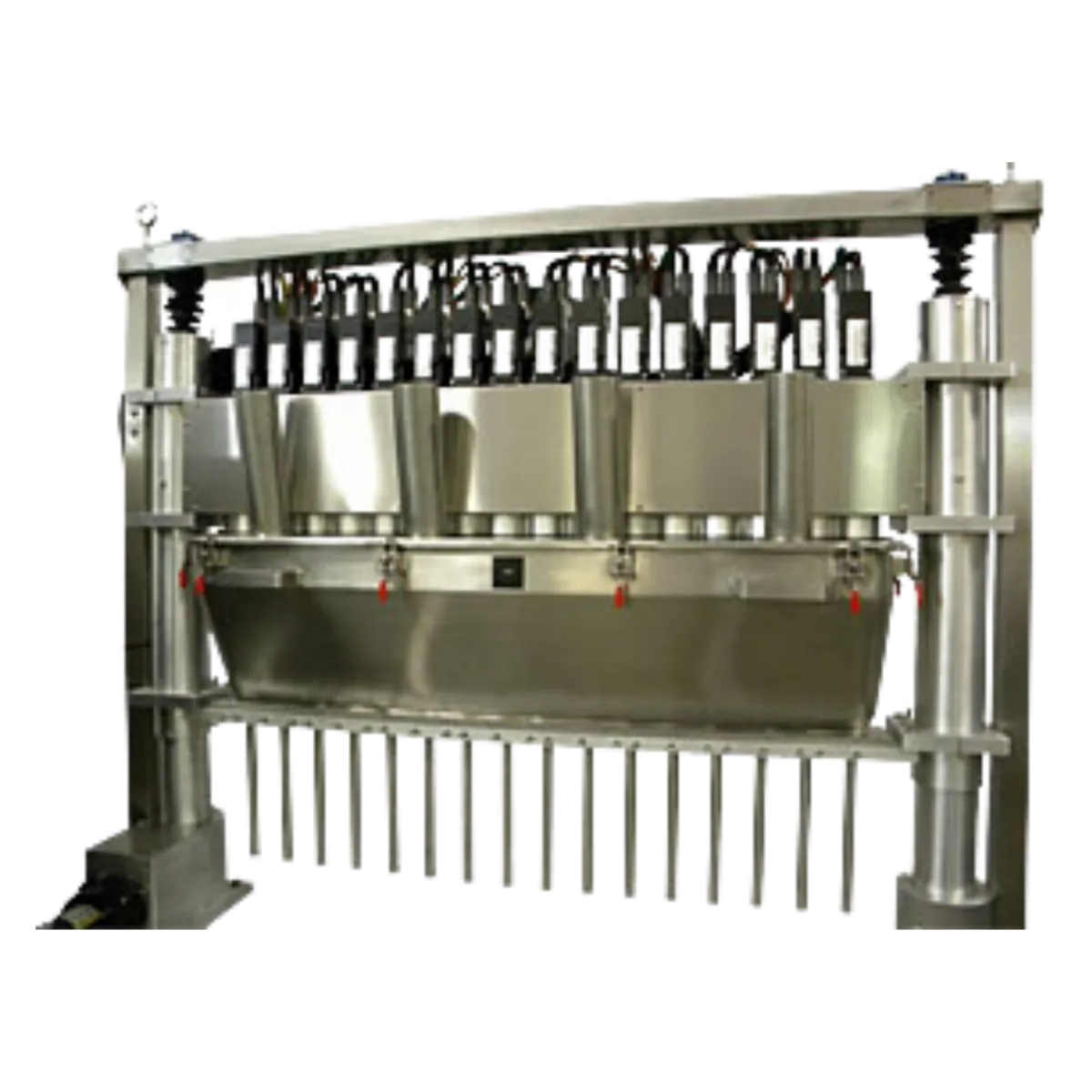

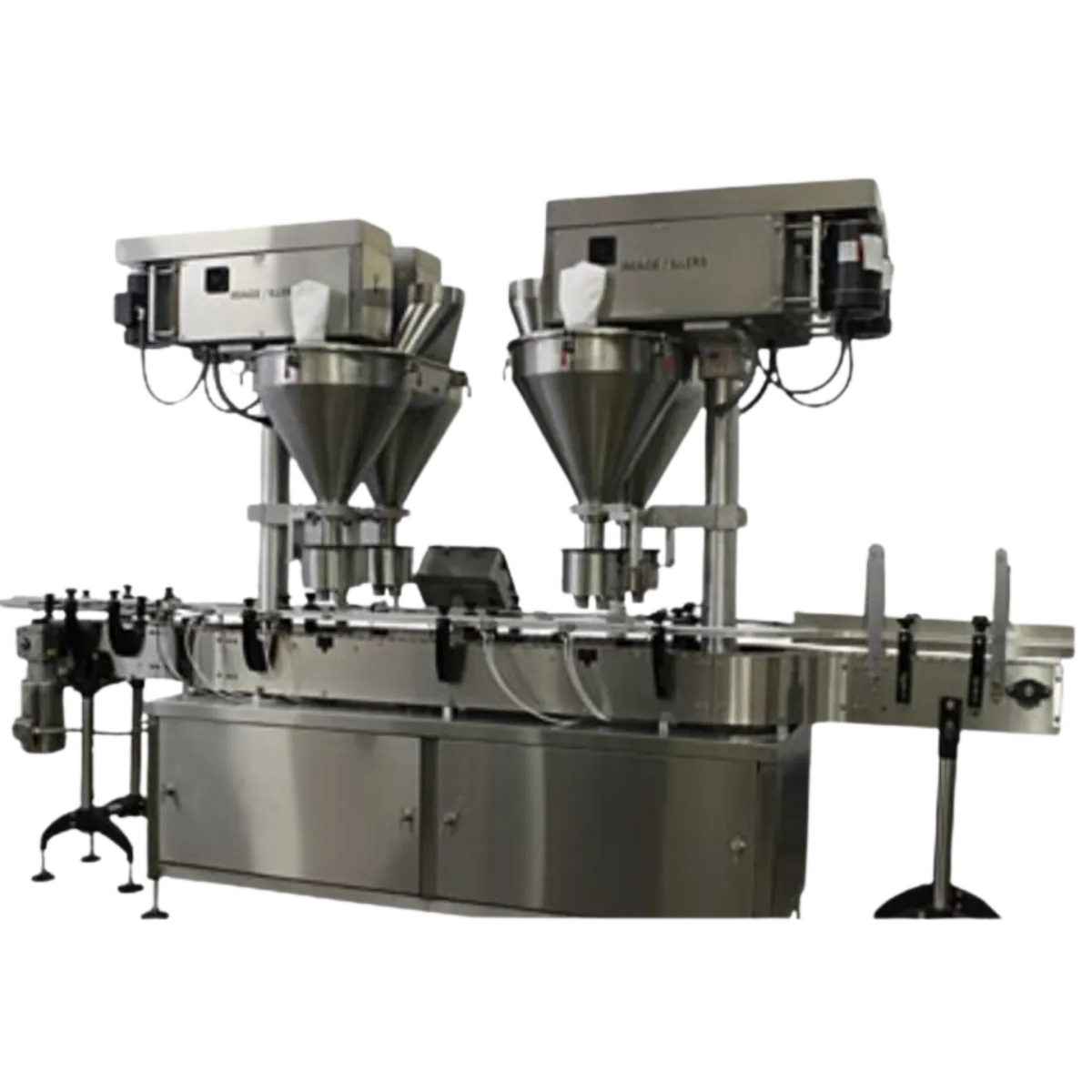

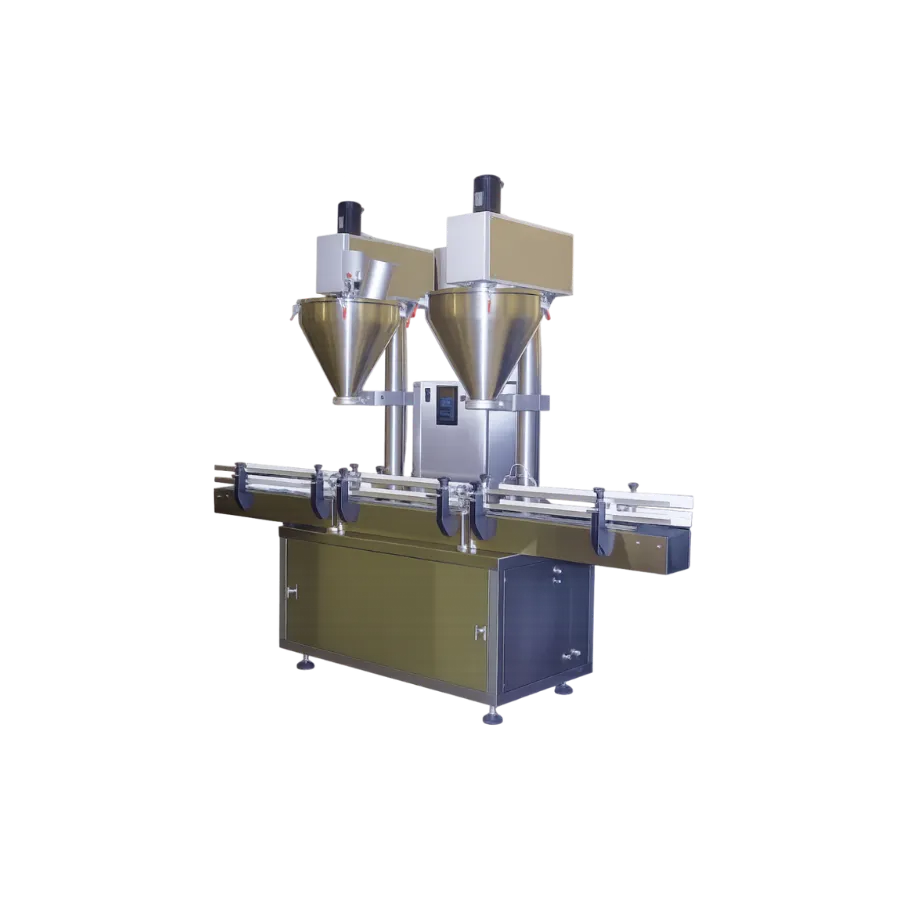

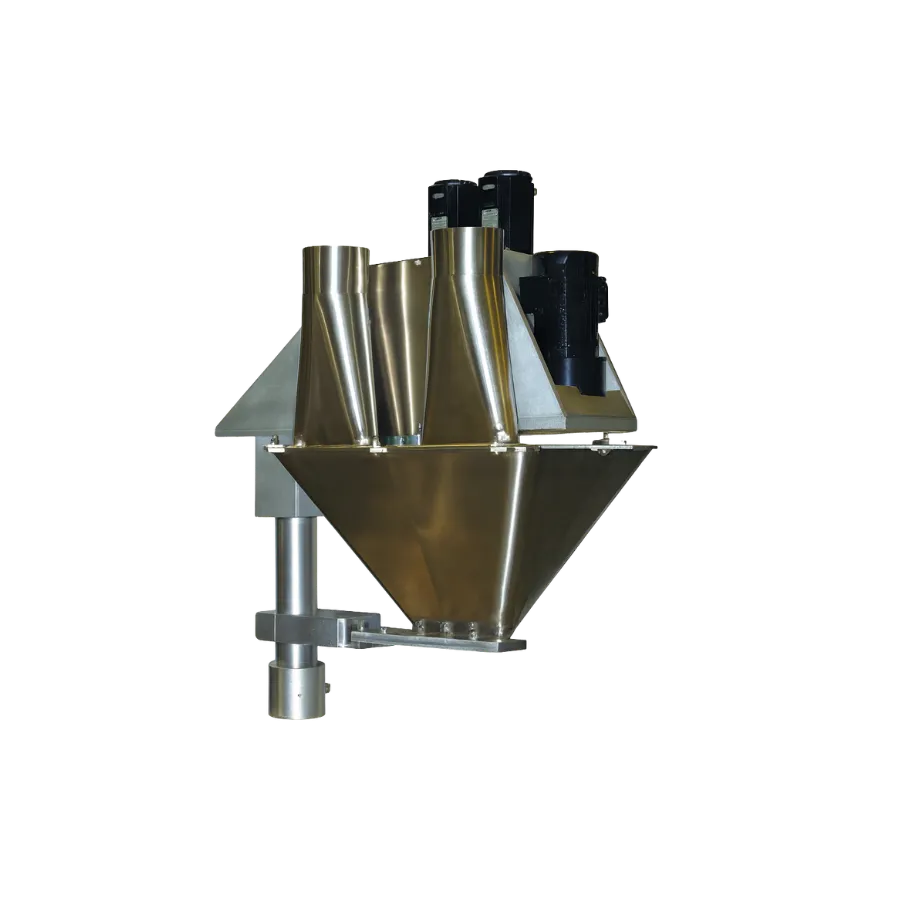

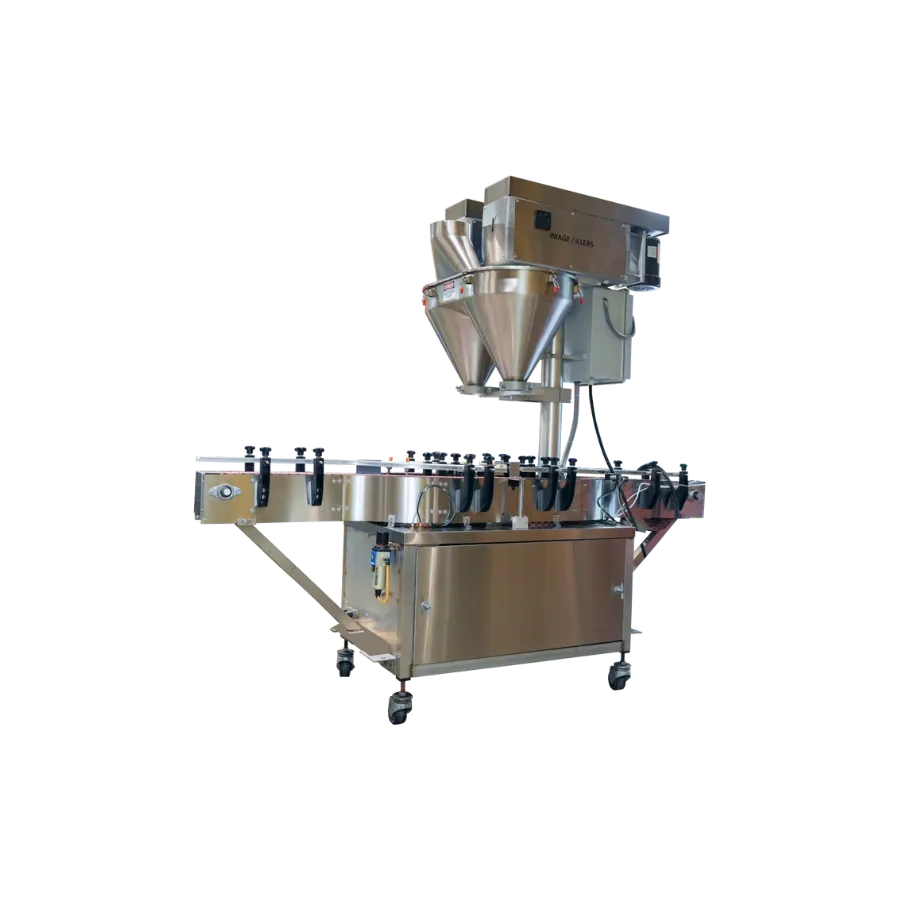

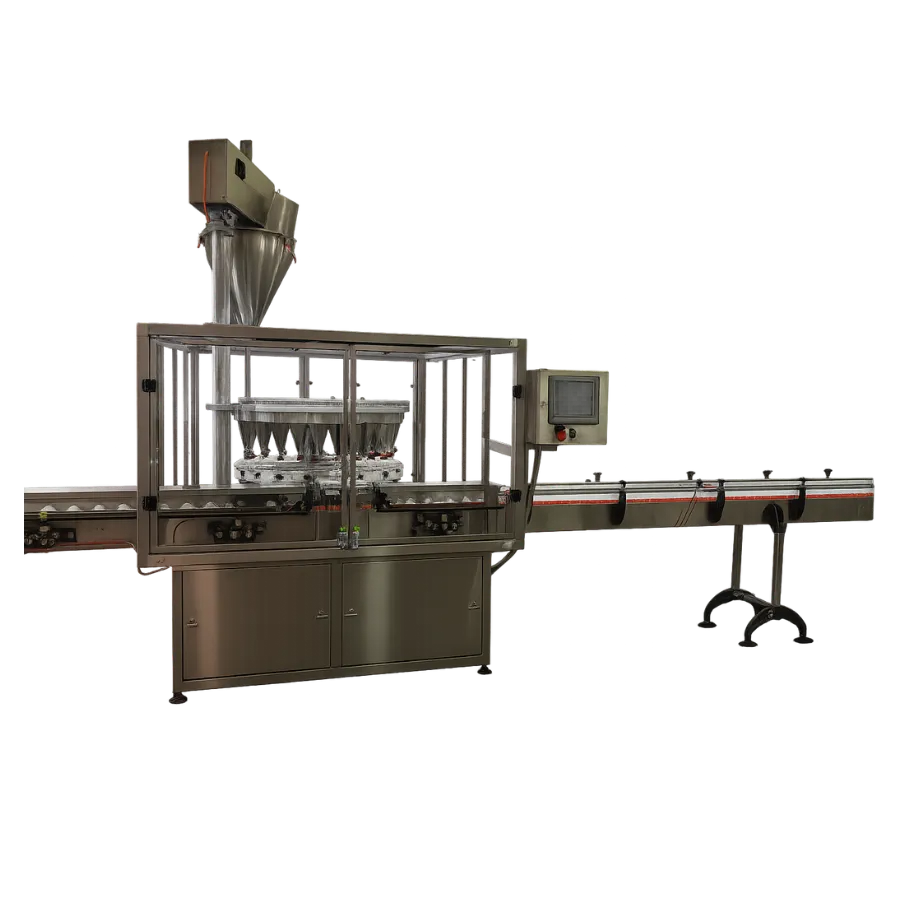

Image 5.5K

Quad head filler & split lane conveyor

Description

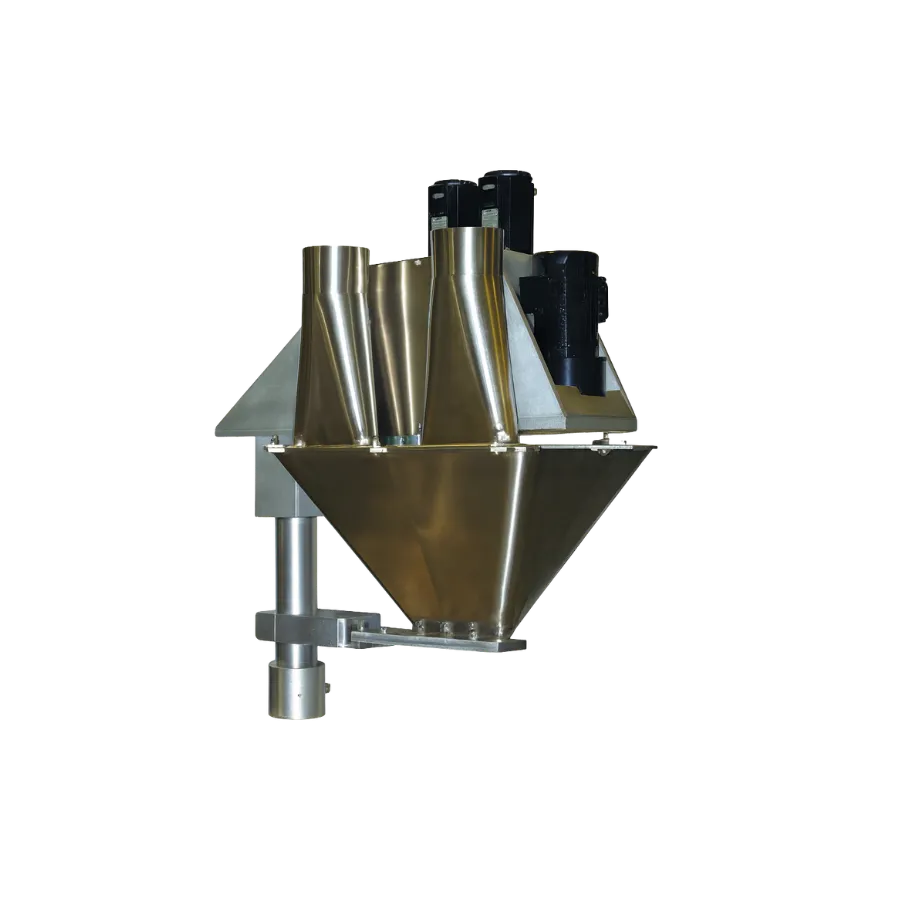

The Image 5.5K is a high-performance quad-head auger filler with adjustable centers ranging from 9” to 20”. Narrower centers are seamlessly accommodated with a custom-fabricated fill head.

Its advanced conveyor system features a single infeed that efficiently splits into two lanes, enabling simultaneous filling of two containers without any empty units passing to a second station. This design delivers a genuine “double your production” solution, maximizing throughput and efficiency.

Features

• Stainless steel and anodized aluminum build for durability

• Four 16-gallon hoppers with quick release clamps for easy removal

• Clutch brake or servo drive motor

• Motor protection

• Agitation blade (prevents product sticking to hopper)

• Split lane stainless steel indexing conveyor

• Allen Bradley PLC

Optional:

• Pneumatic Lift

• Vibration

• Vibration on conveyor for accurate filling

• 36”, 48”, and 60” diameter unscrambling and accumulation tables (pictured with two 36” tables)

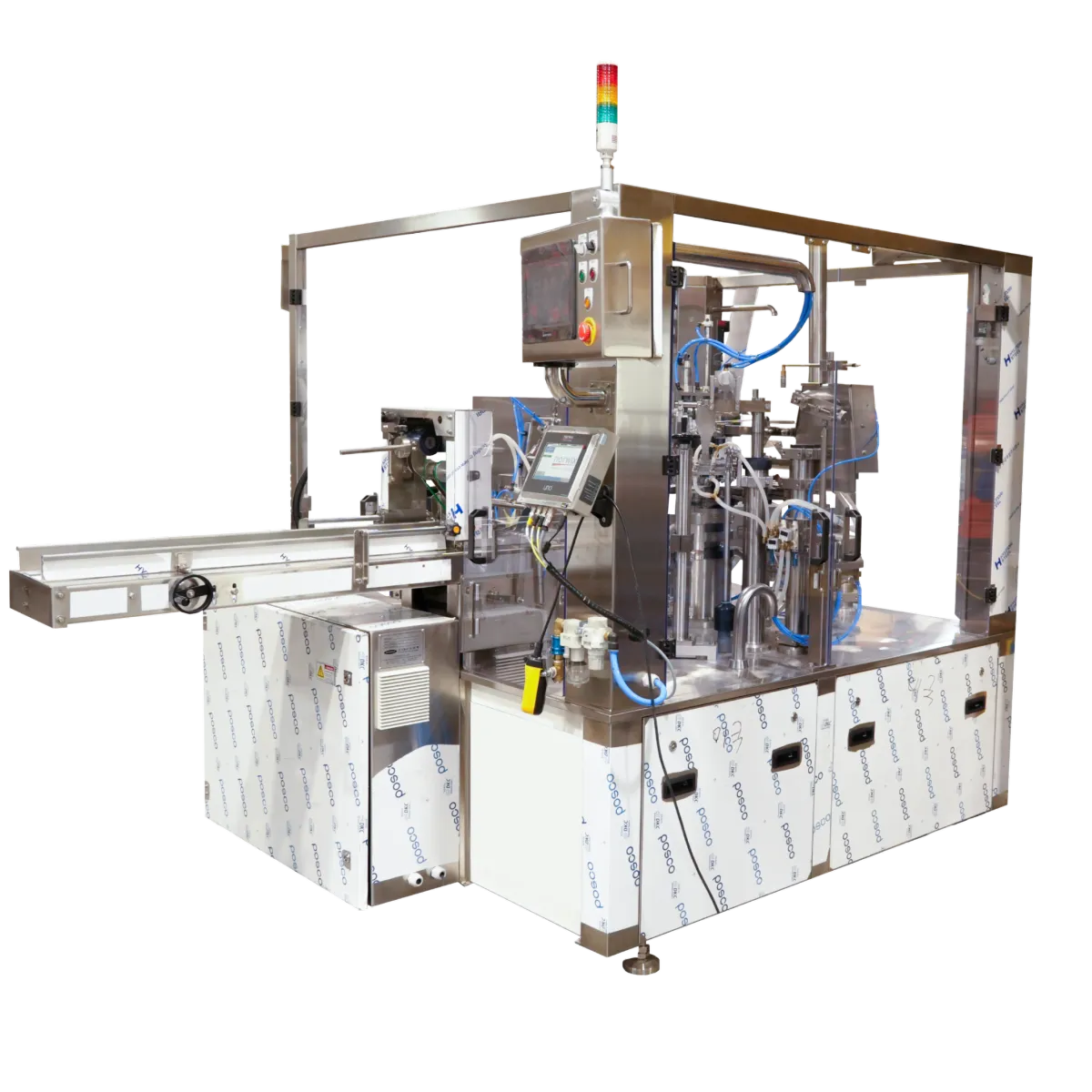

Image 5K Video

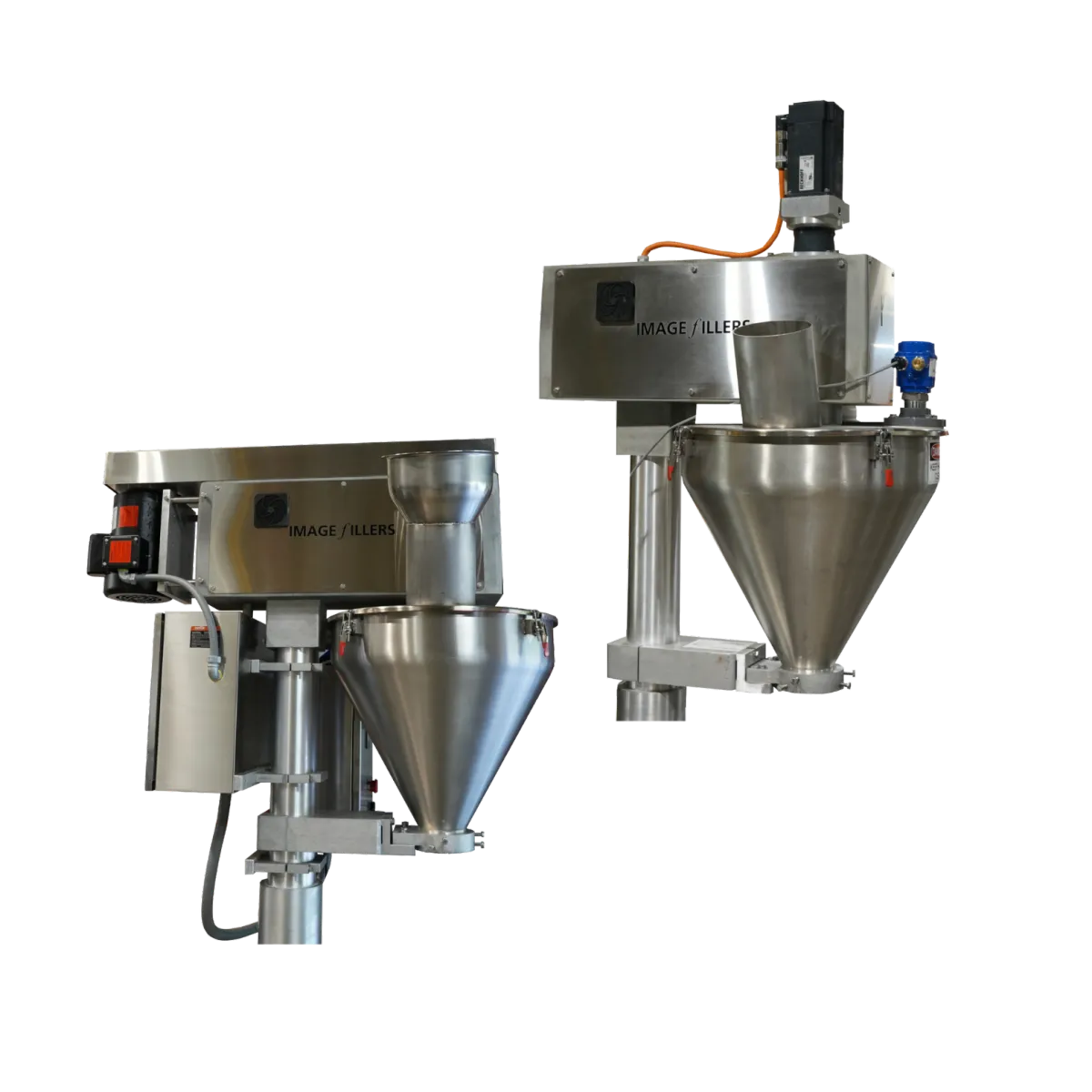

Clutch brake or servo drive?

You can get a clutch brake or servo drive motor with the Image 5K or Image 5500

Clutch brake motor.

Servo drive motor.

Pros

• Lower cost

• Time-tested

Pros

• More accurate

• More reliable / longer lasting

Small PLC system

Advanced PLC system

[ Allen Bradley PLC or Beckhoff PLC system ]

Pros

• Lower cost

• Simple controls

Pros

• More controls

• More memory

• More features

• Larger screen

Ensure proper setup to experience increased accuracy:

• Keep the proper amount of product in the hopper

•use an agitation blade

• Spinner plate has to be at a 45° angle to the bottom of the funnel (free flow auger)

• Use correct tooling based on free flow & non-free flow machines

• Auger has to be in the correct position in the funnel

The latest.

Take a look at what's new, right now.

Top-rated supplier of auger filling machines.

Free Shipping + 2 Free Accessories

Trusted by organizations across the country.

GET $500 OFF ANY ROOFING PROJECT!

#1 Trusted Roofing Company in Orlando

Top Seal Roofing provides homeowners and building owners with safety, quality and professional service all under one roof.

FILL OUT THE FORM BELOW

Get Your Free Estimate

Highest Quality Machinery

Better performance, durability, and reliability compared to others on the market

Expertise and Knowledge

Been in business for over 25 years - knowledgeable guidance and support for customers

Customer Service

Timely and effective communication, quick response times, and effective solutions

[Customer Name]

[“If you could only show your visitor one testimonial from the past...who would it be? Use this section to present a brief quote from your biggest, most compelling success story!”]

[Customer Name]

[“If you could only show your visitor one testimonial from the past...who would it be? Use this section to present a brief quote from your biggest, most compelling success story!”]

[Customer Name]

[“If you could only show your visitor one testimonial from the past...who would it be? Use this section to present a brief quote from your biggest, most compelling success story!”]

LEARN MORE ABOUT OUR

ROOFING PROCESS!

↓ WATCH THIS QUICK VIDEO TO LEARN MORE ABOUT OUR PROCESS! ↓

Which Motor is right for you?

Clutch brake motor

Pros

• Lower cost

Small PLC system

Pros

• Simple controls

Servo drive motor

Pros

• More accurate

• Run at high speeds with minimal maintenance

Advanced PLC system

Pros

• More controls

• More memory

• More features

• Larger screen

[ Allen Bradley PLC or Beckhoff PLC system ]

Clutch brake

motor

Servo drive

motor

Pros

• Lower cost

Pros

• More accurate

• Run at high speeds with minimal maintenance

Small PLC

system

Advanced PLC system

Pros

• Simple controls

Pros

• More controls

• More memory

• More features

• Larger screen

[ Allen Bradley PLC or Beckhoff PLC system ]

Ensure proper setup to experience increased accuracy:

• Keep the proper amount of product in the hopper

•use an agitation blade

• Spinner plate has to be at a 45° angle to the bottom of the funnel (free flow auger)

• Use correct tooling based on free flow & non-free flow machines

• Auger has to be in the correct position in the funnel

Image 5K Dimensions

Auger Filler Machines

Contact

Hours: 9 AM - 5 PM

735 Fox Chase Rd # 111, Coatesville, PA 19320

(610) 466-1440

To purchase a machine, call (610) 466-1440 or email [email protected]

Image Fillers © 2025

Made in the United States