Get $500 in credit on your first machine when you purchase in the month of February. Shop Products

streamline your filling process and boost productivity

GET $500 OFF ANY MACHINE!

Delivers reliable, high-quality, and professional filling solutions to businesses and manufacturers, all from one trusted source. Our commitment to safety ensures peace of mind for our customers.

Trusted by Organizations Nationwide

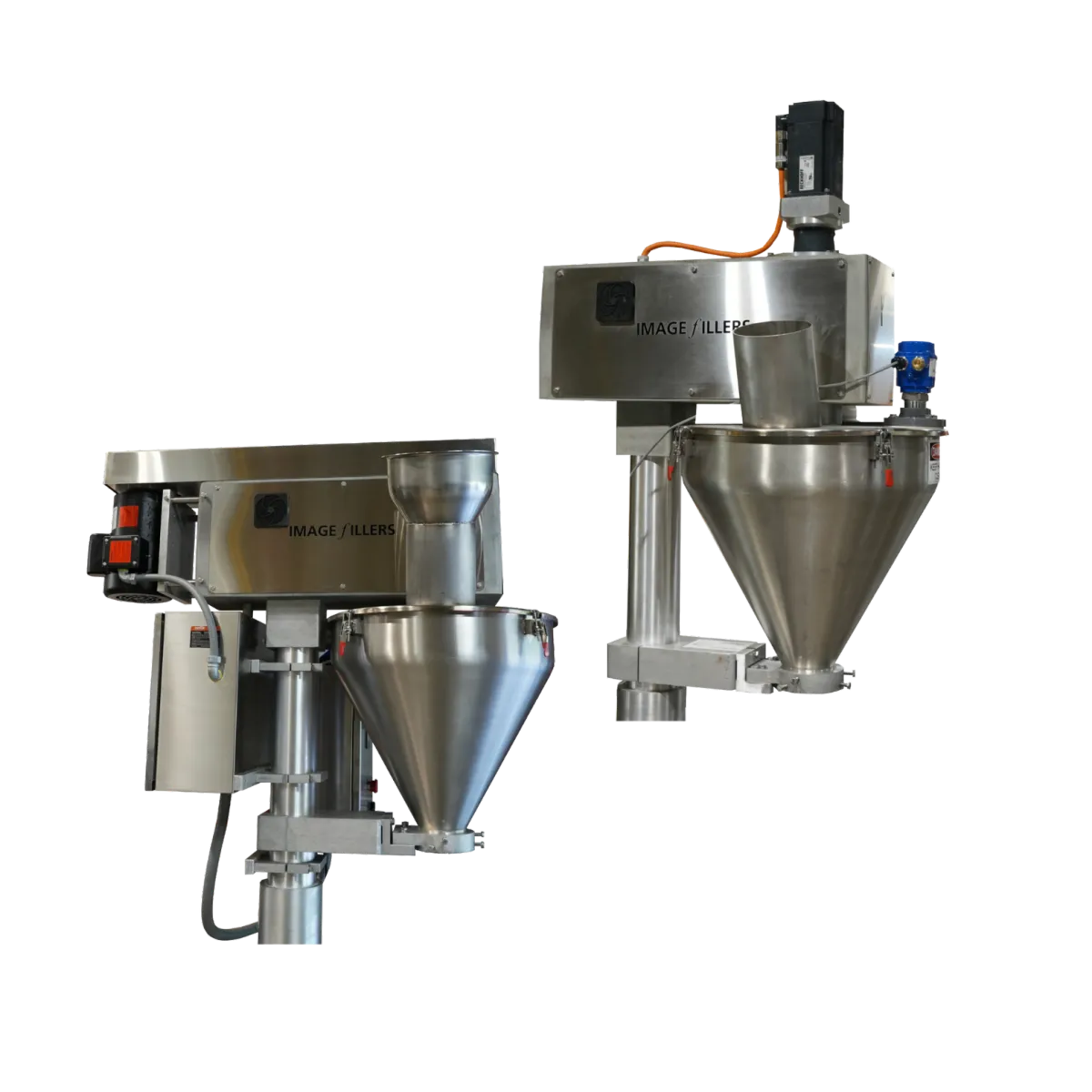

fills 1gram → 5 lBS.

Servo Drive or Clutch Brake Motor.

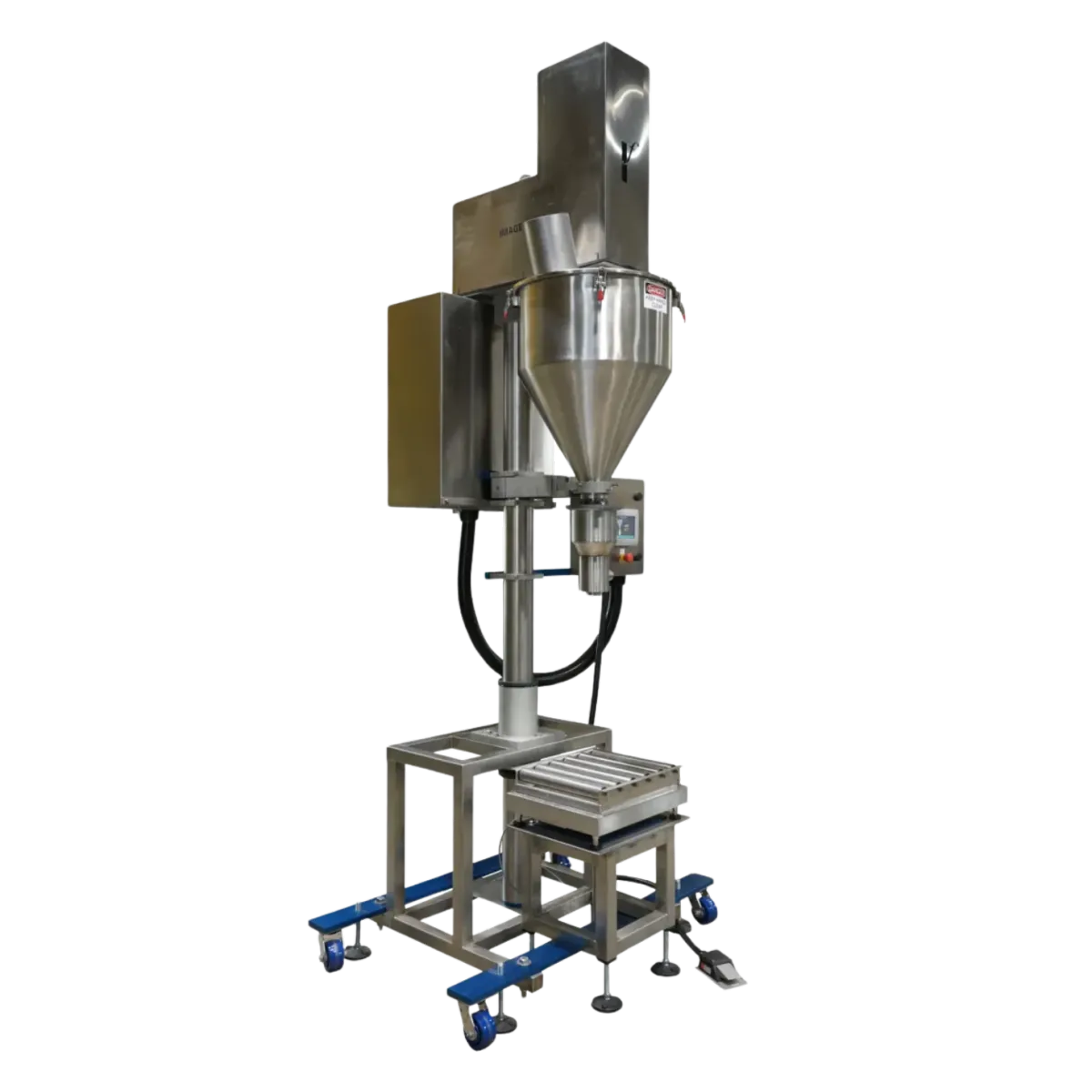

Image 4K

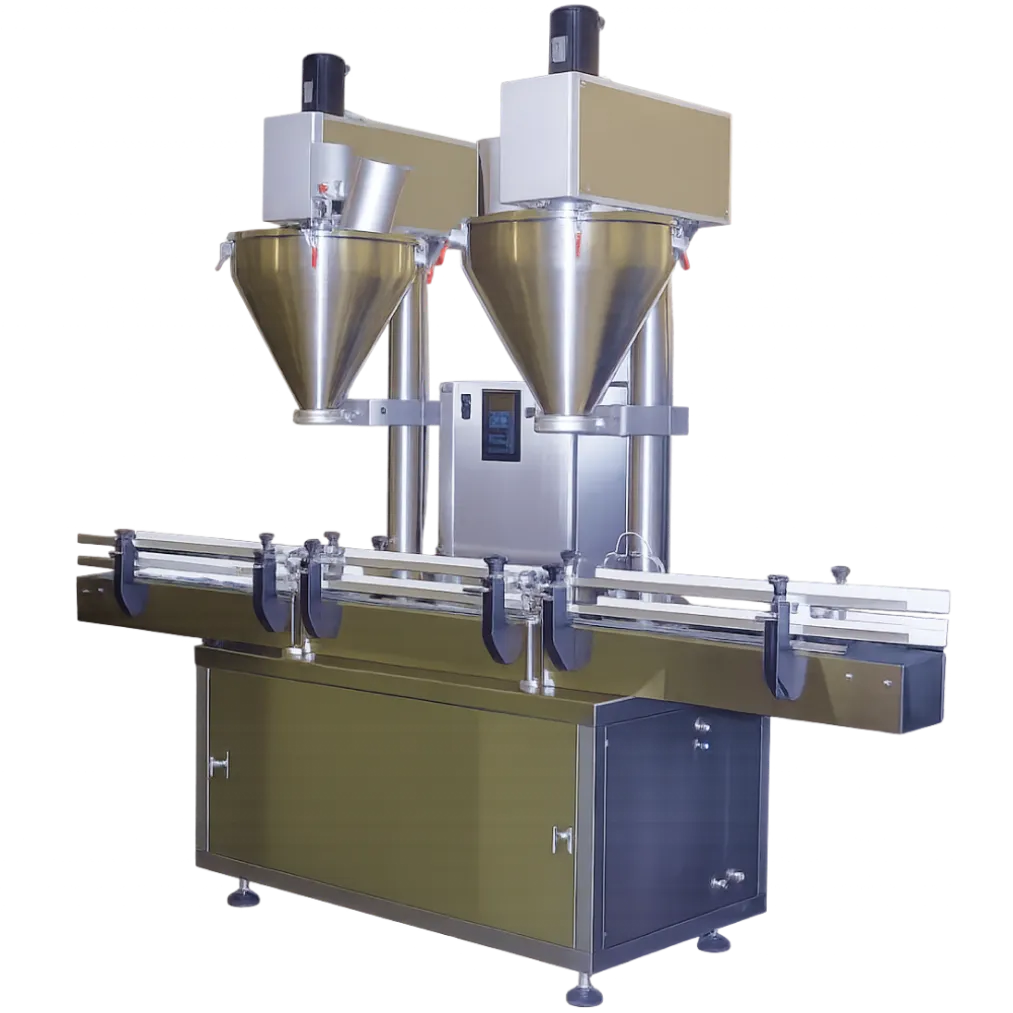

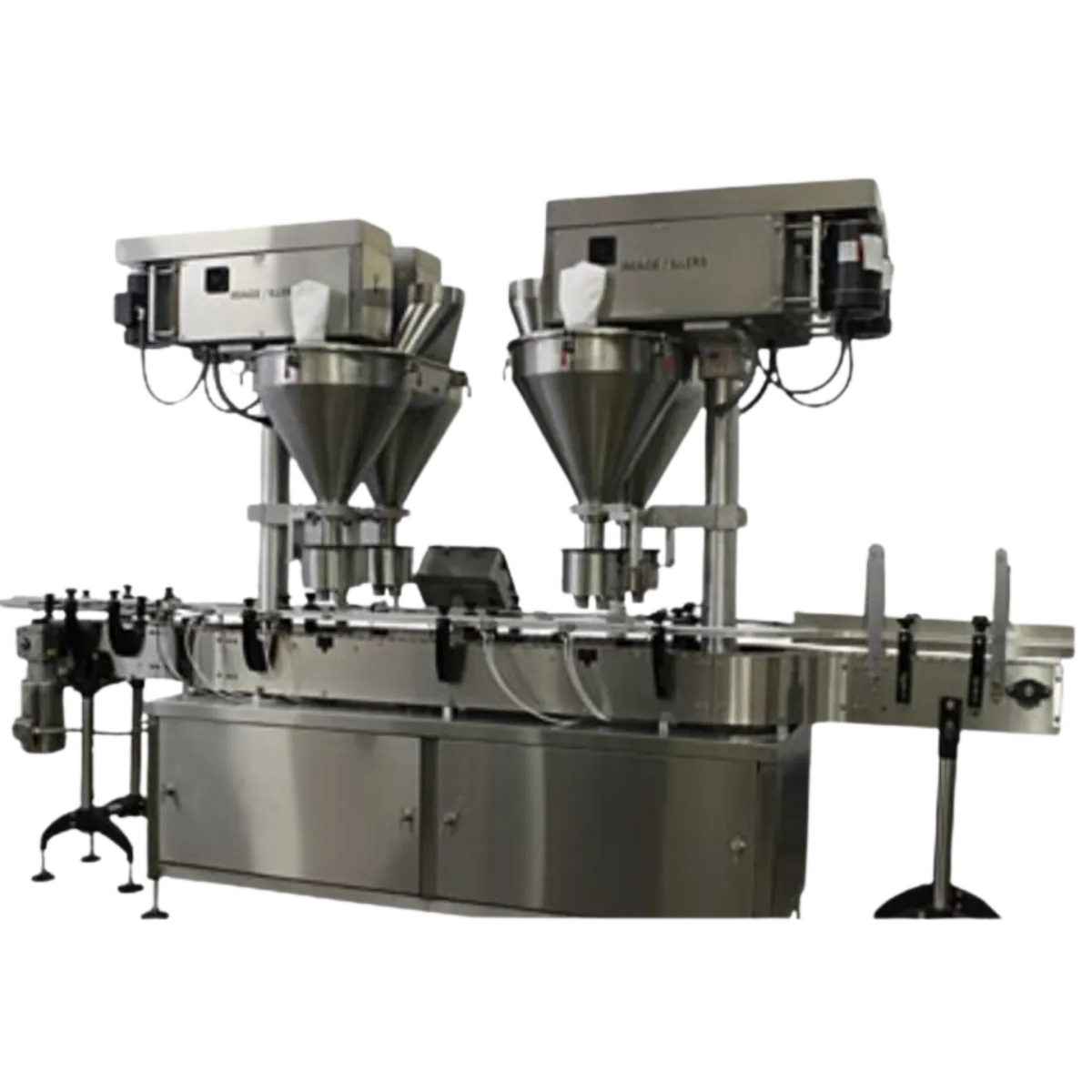

fills 1gram → 5 lBS.

Servo Drive or Clutch Brake Motor.

2 - 4 heads & conveyor.

Image 7K

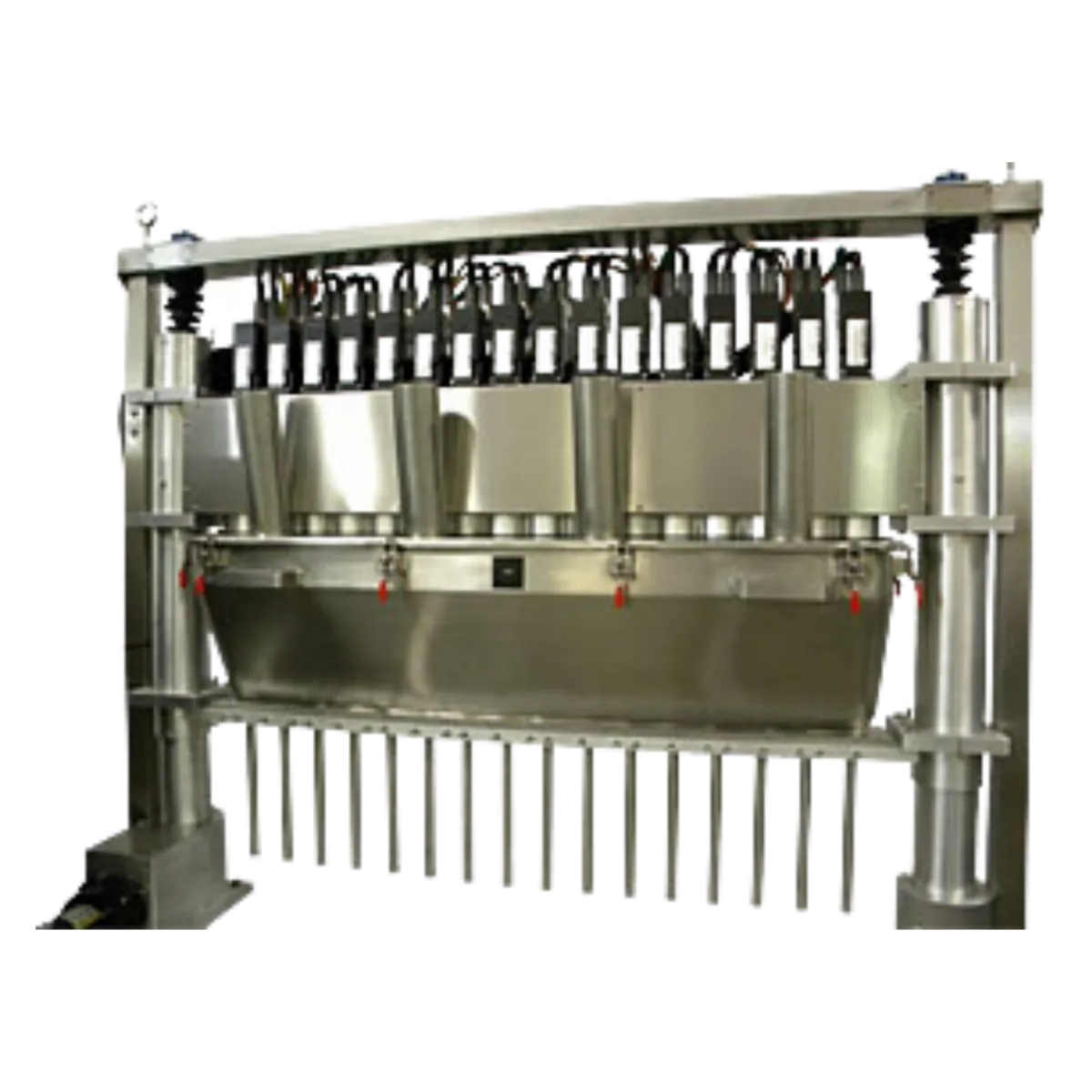

Fills 2-8 packets at once

Multi Head Filler

Perfect Solution

Free standing auger fills 1gram → 5 lBS.

Perfect Solution

Free standing auger fills 1gram → 5 lBS.

Tooling & Parts for your auger filler machine.

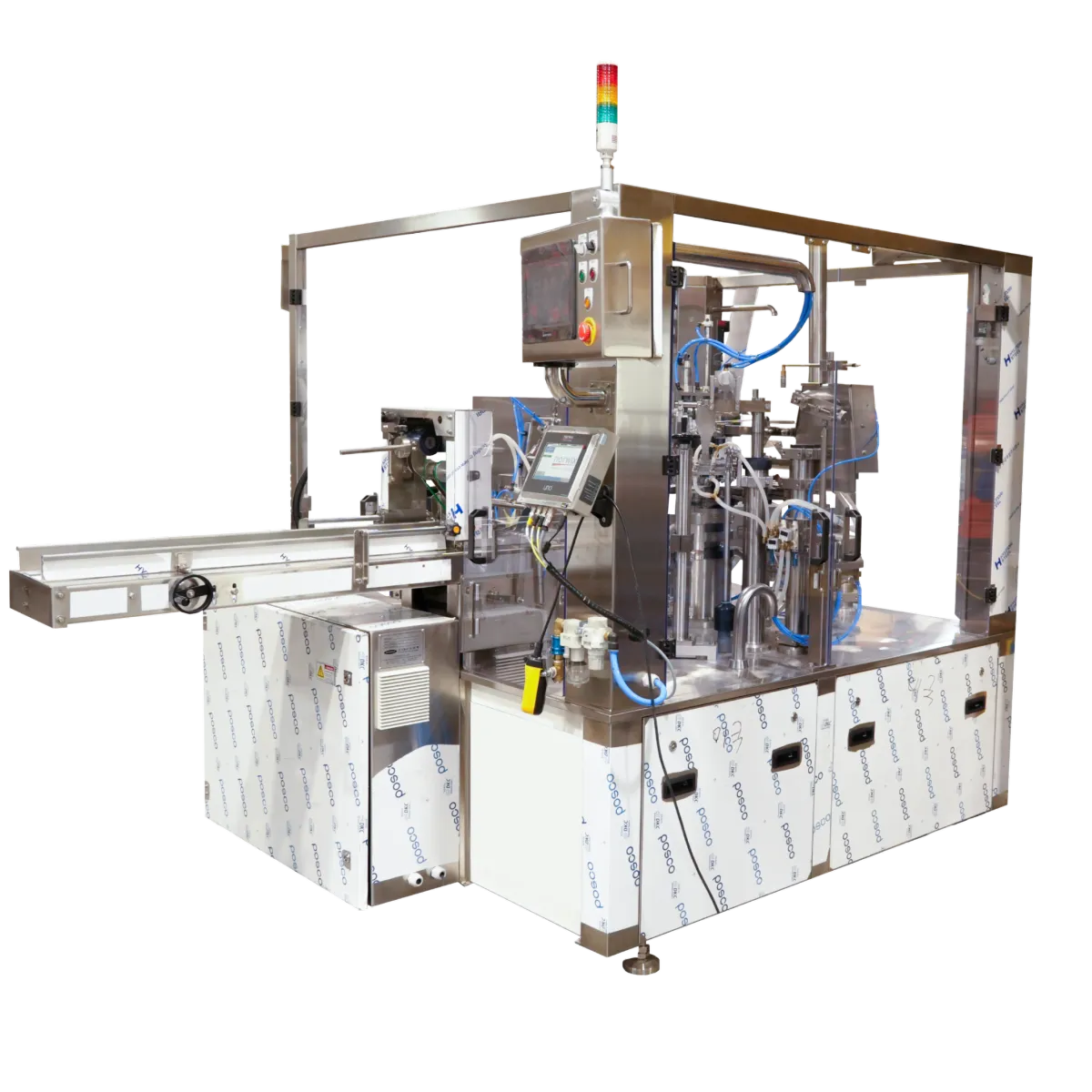

filling & Packaging

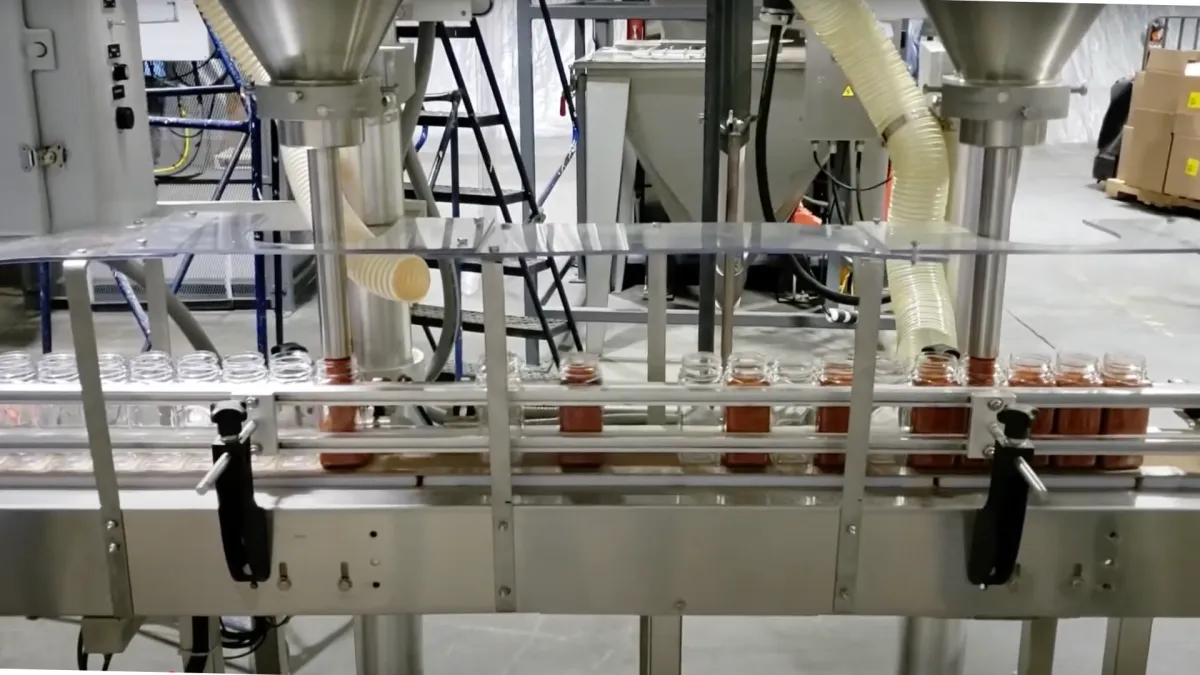

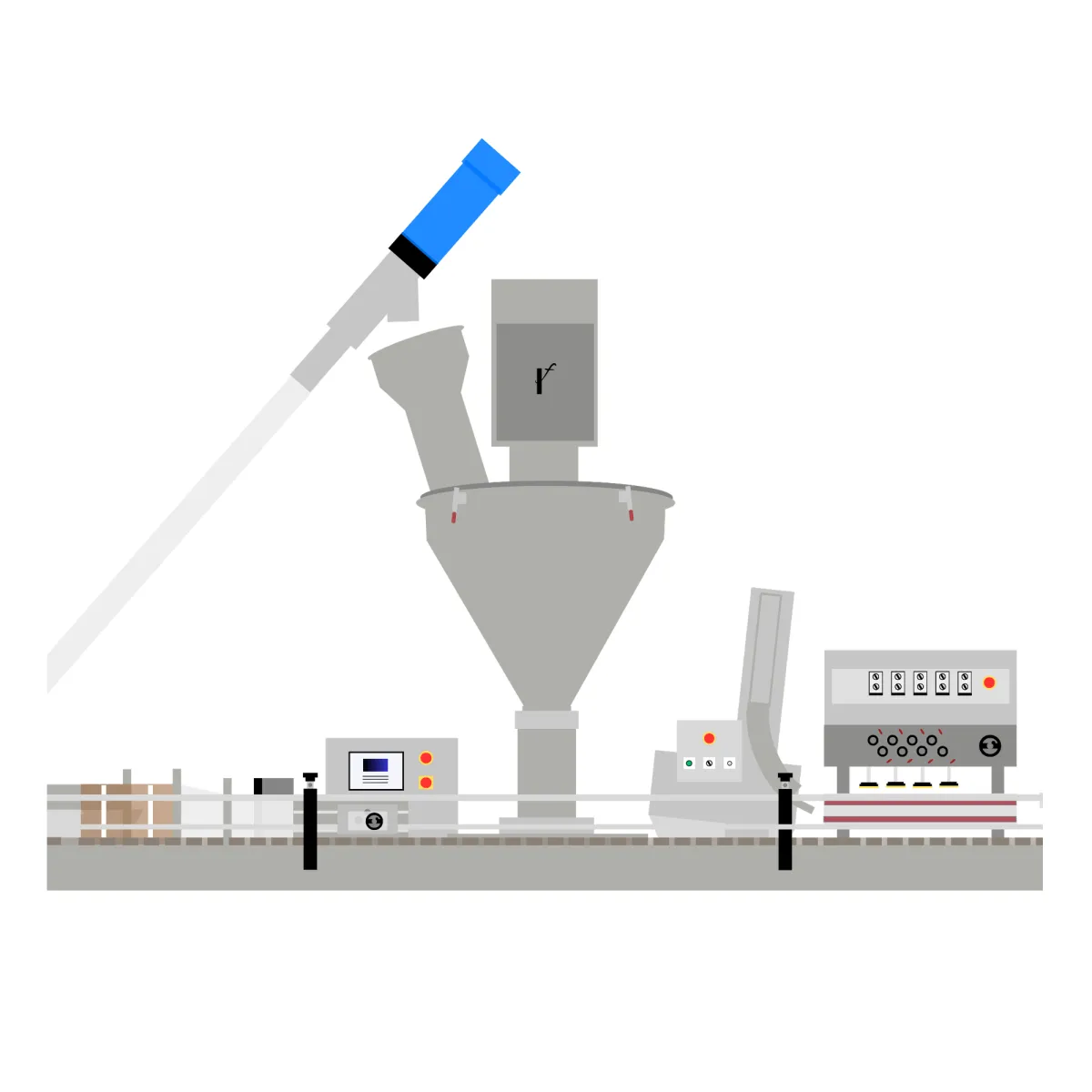

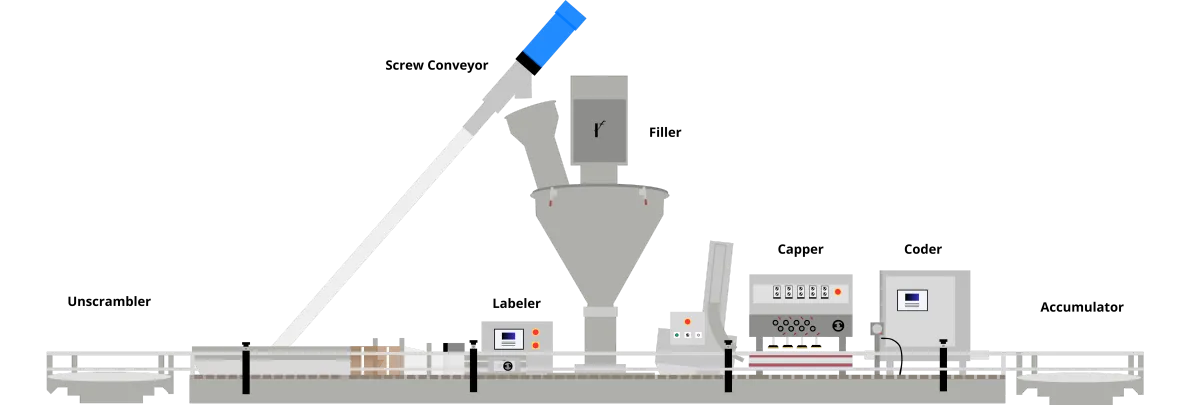

Fully Integrated Packaging Line

Our Fully Integrated Packaging Line offers a complete system that orients, labels, fills, caps, inkjet codes, and collects your products. It can handle powders, viscous products, and liquids, and is fully modular, allowing for additional equipment to be added to the line. Streamline your packaging process with our state-of-the-art technology and cost-effective solution. Contact us to learn more.

Playlists

100+

Clients

100%

5 Star Reviews

200+

Jobs Completed

The latest.

Take a look at what's new, right now.

Top-rated supplier of auger filling machines.

Free Shipping + 2 Free Accessories

Satisfied Customers Speak for Us

Michelle Torres

Image fillers provides excellent products, superior service and offer pricing that is in line with other companies offering the same products. We are always confident when placing an image filler that the equipment will perform as promised.

Jerry Carter

I have purchased several of Image Fillers machines over the years and have been very happy with the machines and the customer service I received from Mike and his team.

Ed Walinski

Mike is a very customer service oriented Sales Manager. I've worked with him for 5-6 years and experienced the same results each time.

Kevin Weber

Mike and his team have solid working knowledge of applications where the equipment is going to be placed. They are responsive to requests and a fair and honest company to work with.

LEARN MORE ABOUT OUR PRODUCTS

↓ WATCH THIS QUICK VIDEO TO LEARN MORE ABOUT OUR PROCESS! ↓

[Customer Name]

[“If you could only show your visitor one testimonial from the past...who would it be? Use this section to present a brief quote from your biggest, most compelling success story!”]

[Customer Name]

[“If you could only show your visitor one testimonial from the past...who would it be? Use this section to present a brief quote from your biggest, most compelling success story!”]

[Customer Name]

[“If you could only show your visitor one testimonial from the past...who would it be? Use this section to present a brief quote from your biggest, most compelling success story!”]

LEARN MORE ABOUT OUR

ROOFING PROCESS!

↓ WATCH THIS QUICK VIDEO TO LEARN MORE ABOUT OUR PROCESS! ↓

Trusted by Organizations Nationwide

Trusted by Organizations Nationwide

June 26, 2024

Fully Automated Bottling Line

The ultimate guide to a fully automate bottling

Fully integrated bottling line components

The bottling line consists of an unscrambler, labeler, screw conveyor, auger filler, conveyor, capper, coder, check weigher, and accumulator.

Unscrambler

The journey begins with the unscrambler. This machine sorts and aligns bottles before feeding them onto the conveyor. This ensures that each bottle is correctly oriented, reducing downtime and preventing jams further down the line.

Labeler

Once the bottles are aligned and moving along the conveyor, the labeler takes over. This machine accurately applies labels to each bottle, ensuring that your branding and product information are prominently displayed.

Screw Conveyor

The screw conveyor transports the product from storage to the auger filler. It automates the feeding process, ensuring a steady supply of product for filling.

Auger Filler

The heart of the operation is the auger filler, which dispenses the exact amount of powder into each bottle.

Capper

After filling, the next step is sealing. The capper securely places caps on each bottle, protecting the contents from contamination and spillage.

Coder

The coder adds essential information such as batch numbers and expiration dates to the bottles. This step is crucial for traceability and compliance with industry regulations.

Double check weigher

The double check weigher machine verifies product weight against set standards, automatically discarding any that fall outside the specified range.

Accumulator

Finally, the accumulator collects the filled, labeled, and capped bottles off the conveyor, organizing them for packaging or further processing.

Is the packaging line worth it?

The packaging line reduces labor costs, boosts production speed, and enhances filling accuracy, which is essential for efficient bulk filling and packing.

Insights in your inbox

Sign up for updates on products, tips, and more

Contact

Hours: 9 AM - 5 PM

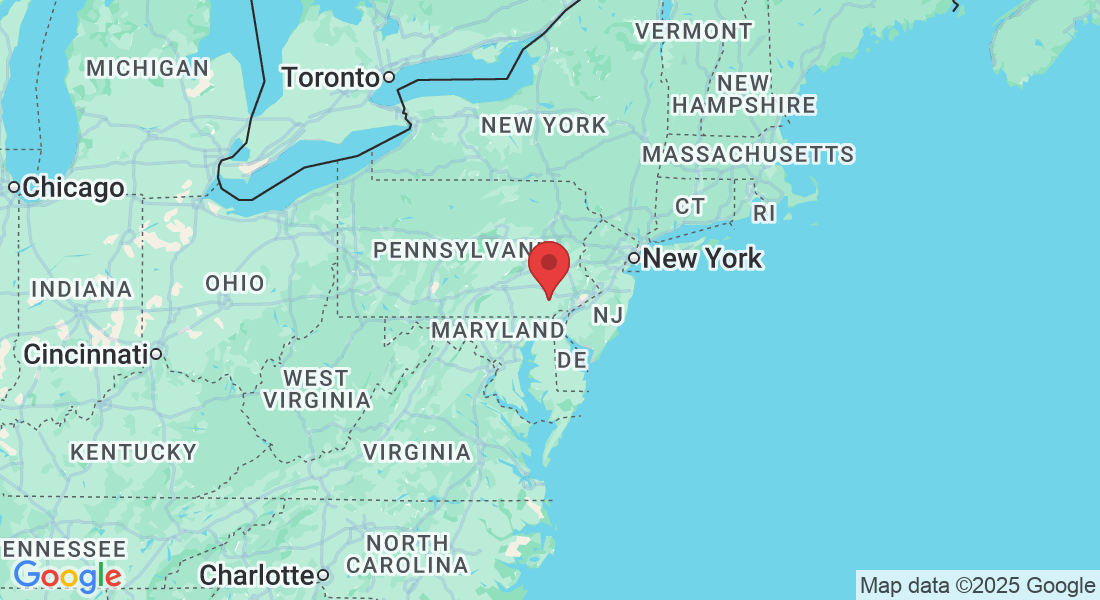

735 Fox Chase Rd # 111, Coatesville, PA 19320

(610) 466-1440

To purchase a machine, call (610) 466-1440 or email [email protected]

Image Fillers © 2025

Made in the United States