Maintenance and Parts Instructionals

In Depth Machine instructional

videos on the Image Fillers app

Gain access to the app when you buy a machine

Maintenance and Parts Instructionals

In Depth Machine instructional

videos on the Image Fillers app

Gain access to the app when you buy a machine

How to replace the slow speed bearing housing

Image Fillers Inc.

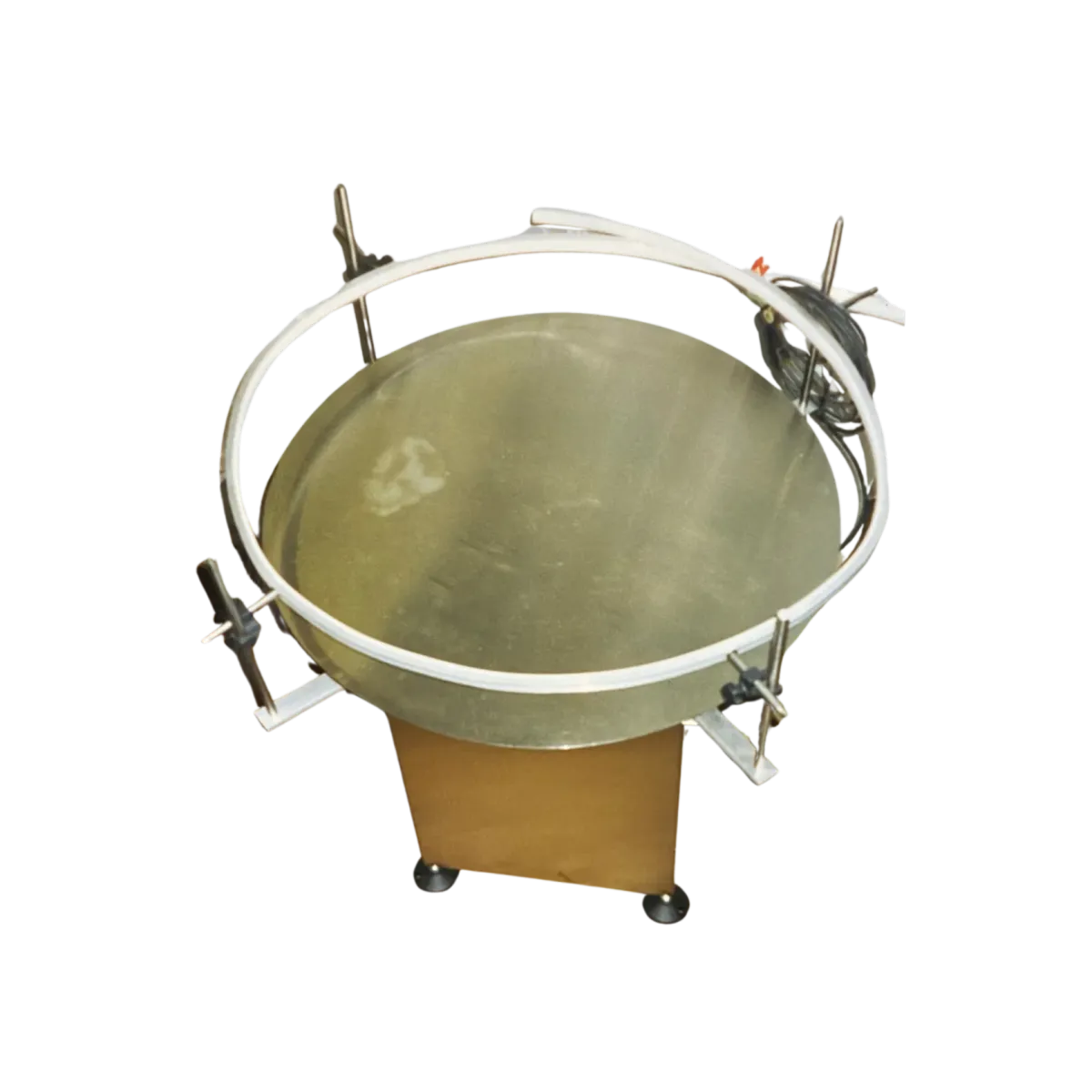

How to Adjust the

Spinner Plate For

Accurate Filling

Image Fillers Inc.

How to Remove and

Reinstall the Clutch

Brake Motor

Image Fillers Inc.

How to Correctly Align your Auger to Avoid Premature Wear and Tear

Image Fillers Inc.

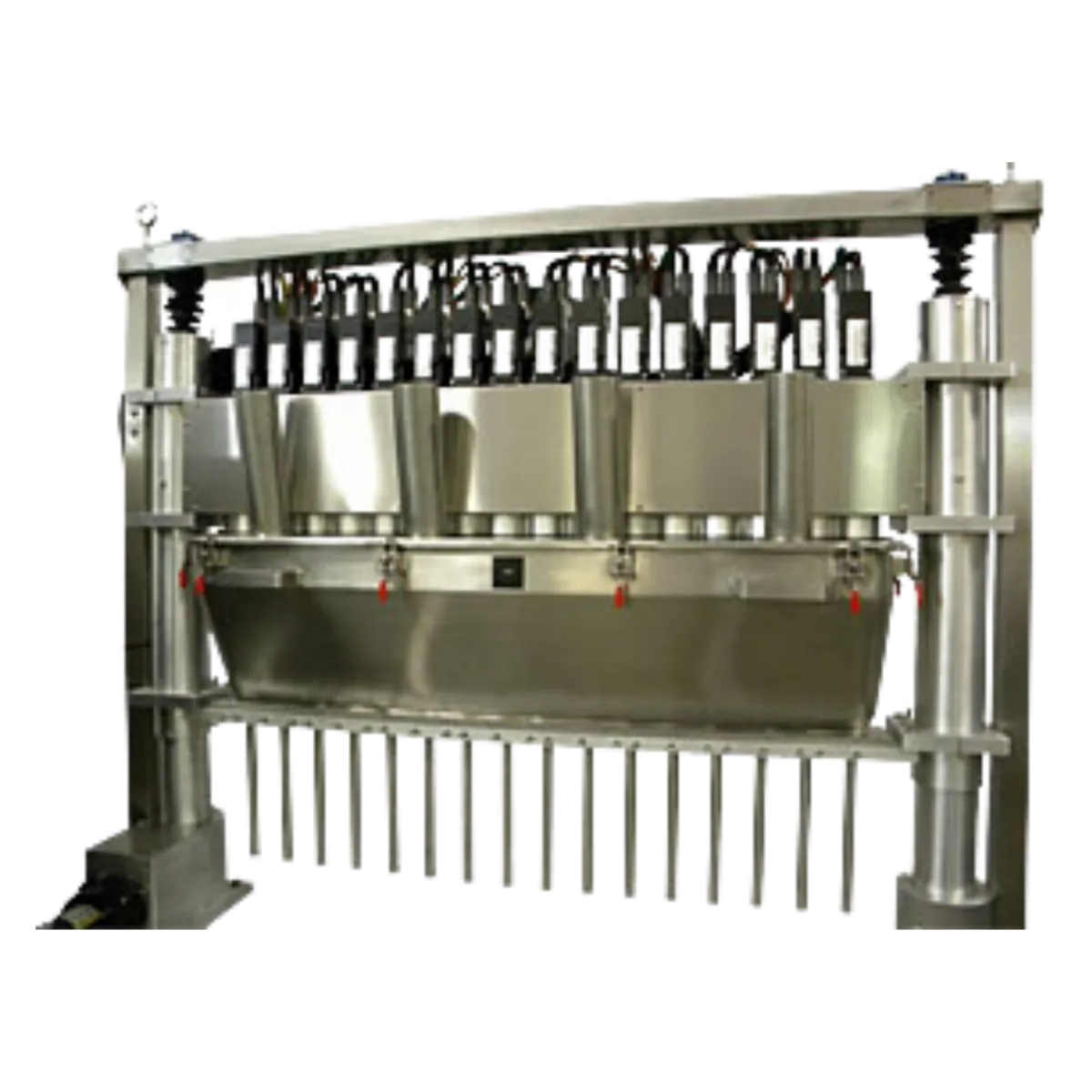

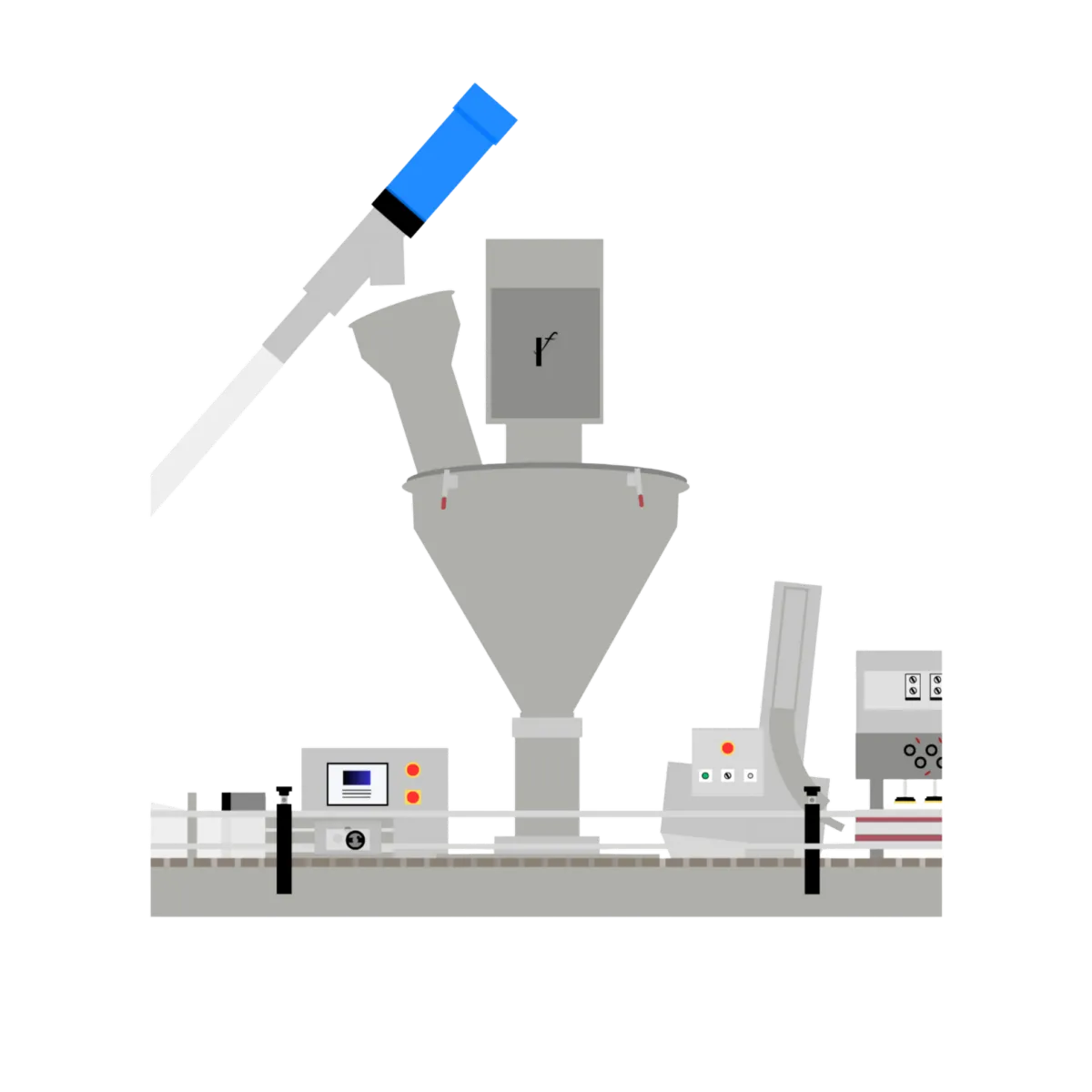

Image Fillers Fully Integrated Packaging Line

Image Fillers Inc.

Beginning of Imagefillers Inc.

1996

Image Fillers Inc.

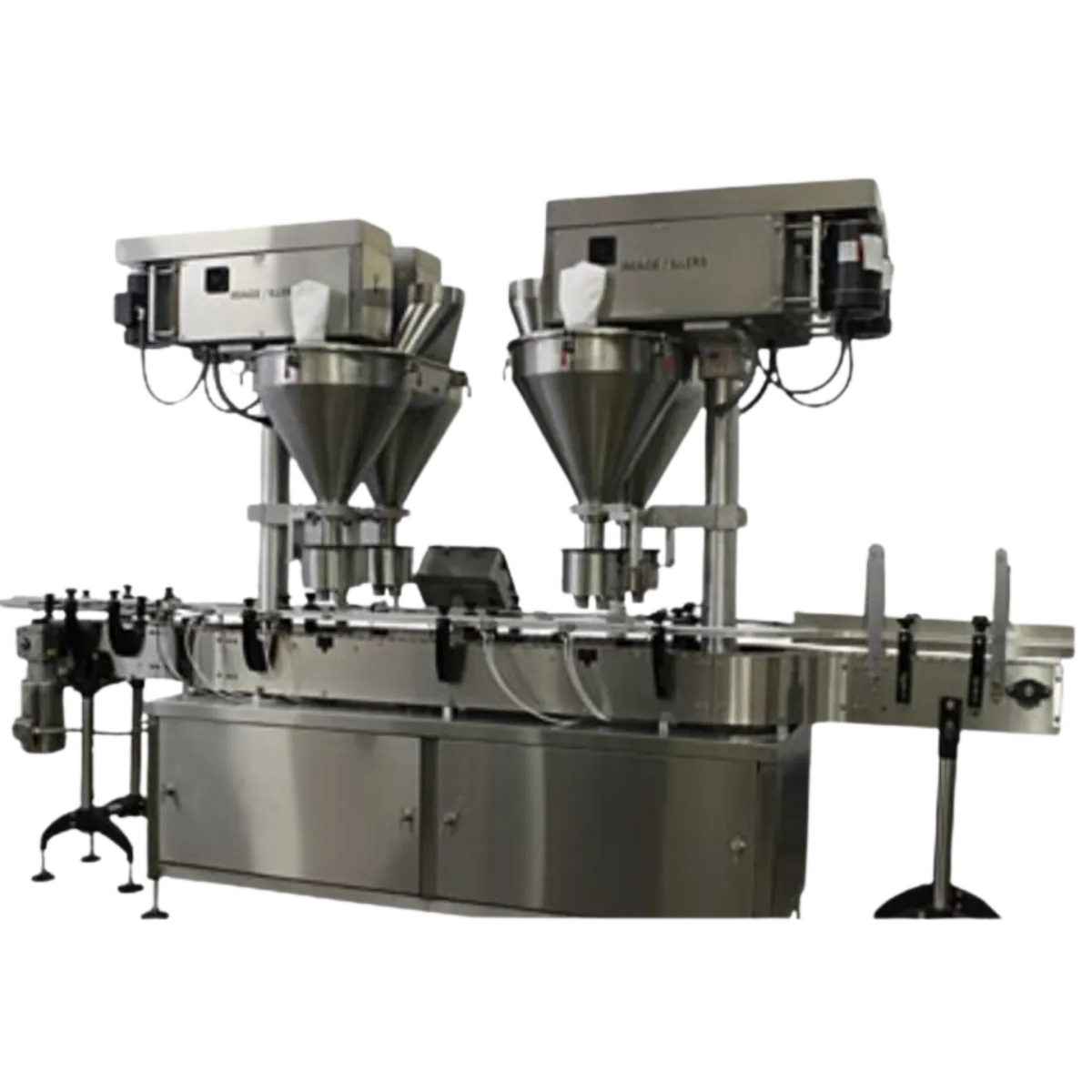

McCormick Spice Line Dual Head Filler

Image Fillers Inc.

Filling Coffee With Image 3500 Servo Auger Filler

Image Fillers Inc.

Perfect Solution Filler Demo - Image Fillers

Image Fillers Inc.

Fill Liquids With Your Powder Filler

Image Fillers Inc.

Should I Automate My Product Filling and Packaging?

Should you continue with manual labor or invest in automated packaging lines? This decision can significantly impact operational efficiency, cost-effectiveness, and overall business growth. Let's delve into the differences between relying solely on manual labor versus automating your product filling and packaging

The Drawbacks of Manual Labor

1. Recruitment Challenges: Manual packaging jobs are often monotonous and repetitive. Finding and retaining employees willing to perform these tasks can be difficult. The quality of work may deteriorate over time due to the tedious nature of the job, leading to inconsistencies and potential errors.

2. Higher Costs: Manual labor can be more expensive than automation when considering the full spectrum of costs, including salaries, health insurance, and liability insurance. For example, hiring employees involves significant expenses such as:

Salary Costs: Paying multiple employees to handle filling, labeling, capping, and printing can quickly add up.

Insurance Costs: Providing health and liability insurance for employees increases operational costs.

Short-term Contracts: For businesses handling large, short-term projects, hiring temporary employees incurs similar costs, making automation a more attractive option in the long run.

The Advantages of Automated Packaging Lines

1. Increased Efficiency and Scalability: Automated packaging lines excel in handling high volumes of repetitive tasks with precision and consistency. For instance, filling coffee, spices, nutraceuticals, viscous products, or liquids into 1000 packages or bottles a day is effortlessly managed by machines. This scalability enables businesses to take on larger contracts and expand their operations without worrying about labor constraints.

2. Cost Savings: Automation can lead to substantial cost savings by reducing the number of employees needed for packaging operations. Consider this scenario:

A fully automated packaging line costing $300,000 can package around 30 spice containers per minute.

Without the machine, you might need 5 people for filling, 2 for labeling, 2 for capping, and 1 for printing—totaling 10 employees.

With an average salary of $50,000 per employee, labor costs amount to $500,000 annually.

An automated line requires only 2 operators, reducing labor costs to $100,000.

Savings Calculation:

Manual Labor: $500,000/year

Automated Line: $300,000 (initial investment) + $100,000 (labor) = $400,000/year

In the first year, automation saves $100,000. Over time, the savings compound, potentially saving up to $400,000 annually per machine. Additionally, automated machines, with proper maintenance, can last indefinitely, providing long-term financial benefits.

3. Enhanced Business Opportunities: Investing in automated packaging lines can open doors to new business opportunities. Companies that lack the capability to handle large-scale projects often miss out on lucrative contracts. By automating, you can confidently quote and secure these projects, increasing production speed and reducing costs.

Financing Options

Many businesses find it challenging to manage the substantial upfront cost of a packaging line, which can reach $300,000. To alleviate this financial burden, we offer flexible monthly payment plans. You can lease-to-own the machine over 36 months for $9,680 per month, 48 months for $7,500 per month, or 60 months for $6,227 per month. These figures are illustrative, as actual prices may vary. Contact us today to receive a personalized quote and explore the best option for your needs.

Conclusion

Automating your product filling and packaging processes offers numerous benefits, including cost savings, increased efficiency, and the ability to scale operations. While the initial investment in machinery may seem significant, the long-term financial advantages and enhanced business opportunities make it a worthwhile decision.

If you're ready to take your packaging operations to the next level, consider investing in a fully integrated packaging line. Contact us today to learn more about our automated solutions and how they can revolutionize your business.

Visit the fully integrated packing line page to learn more: imagefillers.com/packaging-line

Copyright © 2024 Image Fillers Inc. All rights reserved.

Made In The United States