Watch Image Fillers

Machines In Action.

Watch videos of our Image 3500 transformation played to the Rocky movie soundtrack. Other videos include the perfect solution machine filling cannabis powder and more auger demos.

Explore our filling and packaging machines.

How to Increase Auger Filler Production Speed: Dual Head Filler and Split Lane Conveyor

Maximizing Production Speed with Auger Fillers: Dual Head and Split Lane Conveyors

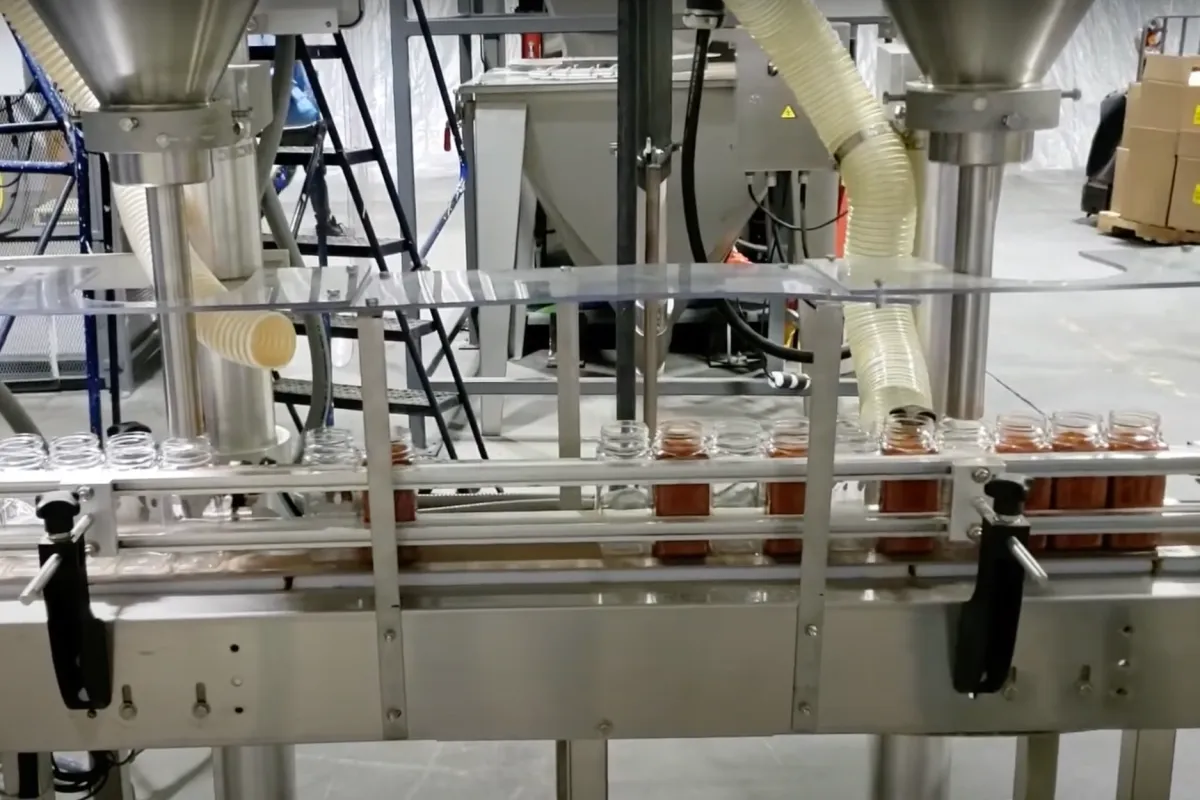

When it comes to optimizing the production speed of auger fillers, there are two effective strategies: employing dual head fillers and utilizing split lane conveyors. These methods can significantly enhance efficiency in packaging lines, ensuring faster throughput without compromising on accuracy.

Dual Head Fillers: Boosting Efficiency

Dual-head auger fillers operate by doubling the filling capacity on a single conveyor belt. Here’s how it works: the first auger fills every other container, while the second auger fills the remaining containers. This setup theoretically suggests a doubling of speed. However, due to the skipped containers occupying space, the second auger may take slightly longer to reach its designated containers. This results in an overall production increase of approximately 1.75 times the original speed.

It's important to note that wider containers or irregular spacing can affect this efficiency, as they may cause delays in the auger's filling cycle. Despite this, dual head fillers remain a robust choice for enhancing production rates without the need for additional equipment.

Split Lane Conveyors: Doubling Output

Alternatively, split lane conveyors involve two separate conveyor belts, effectively doubling the production speed compared to a single conveyor setup. This approach mimics the efficiency of having two auger filler machines without the added cost and space requirements. By streamlining the flow of containers, split lane conveyors minimize bottlenecks and optimize the overall packaging process.

Combining Strategies for Maximum Efficiency

For those seeking even greater production gains, combining both dual head fillers and split lane conveyors can achieve remarkable results. By integrating these technologies, production speeds can be accelerated by approximately 3.75 times compared to traditional single auger setups. This powerful combination not only boosts throughput but also enhances operational efficiency and cost-effectiveness.

Choose Image Fillers for Enhanced Productivity

At Image Fillers, we offer advanced solutions tailored to meet your packaging needs. Our Image 4K features the innovative dual head auger filler, perfect for achieving significant speed enhancements in your production line. For those looking to maximize efficiency further, our Image 5K includes both split lane and dual head technologies, ensuring unparalleled throughput capabilities.

Get in touch with our team today to learn more about how these technologies can increase your production speed and efficiency – your partner in packaging innovation.

Copyright © 2024 ImageFillers Inc. All rights reserved.

United States

Facebook

Instagram

X

LinkedIn

Youtube