Watch Image Fillers

Machines In Action.

Watch videos of our Image 3500 transformation played to the Rocky movie soundtrack. Other videos include the perfect solution machine filling cannabis powder and more auger demos.

Explore our filling and packaging machines.

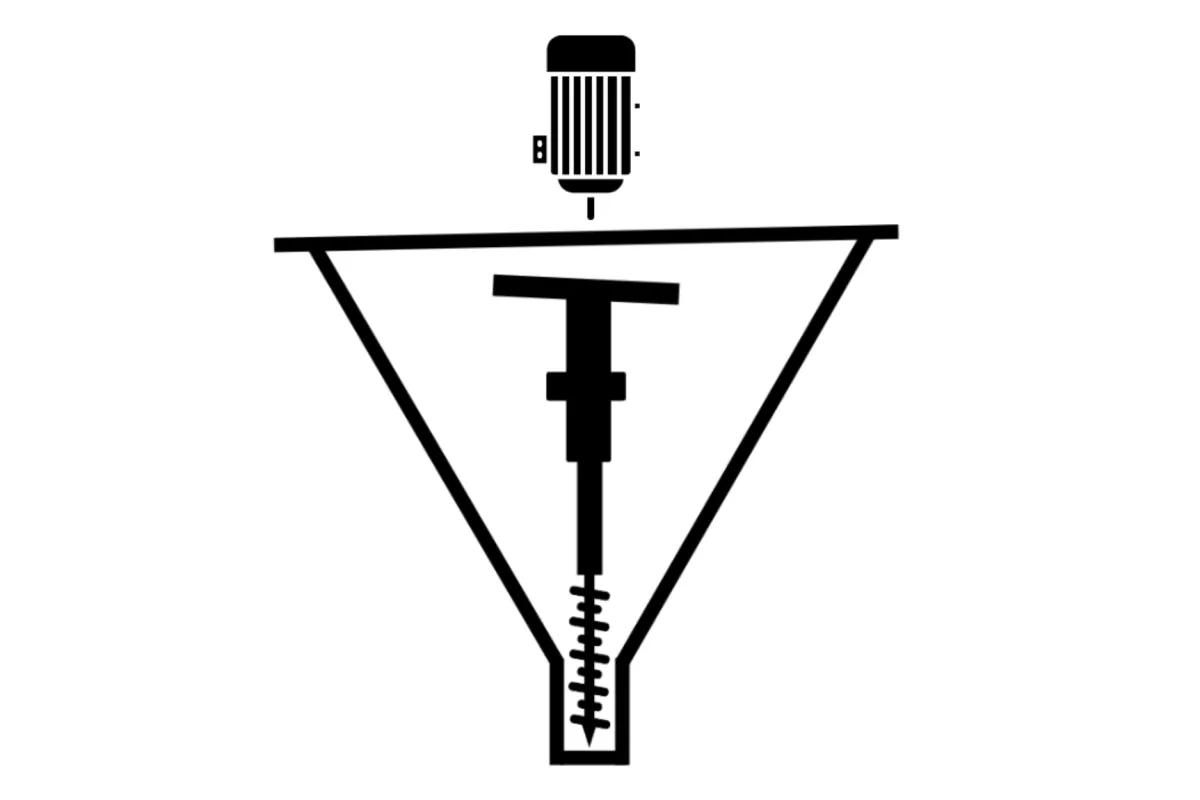

Benefits of a Servo Drive Auger Filler

When it comes to auger fillers, upgrading to a servo motor can significantly enhance your packaging line's efficiency and accuracy. Here's why you should consider a servo motor auger filler for your operations.

Direct Drive Efficiency

One of the key advantages of a servo motor in an auger filler is the direct drive system. Unlike traditional systems like our Image 2000, which use pulleys and belts to drive the auger, a servo motor is directly in line with the auger. This setup eliminates the wear and tear associated with pulleys and belts, ensuring a more reliable and maintenance-free operation.

High-Speed Performance

Servo motors are designed to operate at high speeds without compromising longevity. This is particularly beneficial when mounting the auger filler on form-fill-seal machines that produce bags at speeds of 80 to over 100 bags per minute. A servo motor can keep up with these high speeds without heating up or wearing down prematurely, unlike clutch systems which may eventually fail under such conditions.

Precision and Accuracy

The precision of a servo motor is unparalleled. It can turn the auger within one one-hundredth of a turn, ensuring extremely accurate filling. Unlike clutches, which can have a slight coast after stopping, a servo motor stops precisely when instructed. This level of accuracy is crucial for maintaining consistent fill weights and reducing product giveaway.

Versatile Speed Control

Servo motors offer versatile speed control through a programmable logic controller (PLC). You can easily adjust the auger's speed from 0 to 1200 RPM to accommodate different products and packaging requirements. For instance, one powder might need to run at 300 RPM, while another requires 700 RPM. With a servo motor, you can set these speeds through the PLC, allowing for seamless transitions between different products.

Customizable Torque

The torque capabilities of a servo motor can be tailored to your specific product needs. While a clutch brake system provides significant torque, a servo motor can be sized accordingly, and a gear reducer can be added for additional torque if needed. This customization is ideal for handling a range of products, from easy-to-run materials like coffee to more challenging substances like putty.

Ensuring Proper Setup

To maximize the benefits of a servo motor auger filler, proper setup is essential. Here are a few tips:

Maintain Proper Product Levels: Ensure the hopper has the correct amount of product.

Use an Agitation Blade: This helps maintain consistent product flow.

Set the Spinner Plate Correctly: For free-flow augers, the spinner plate should be at a 45° angle to the bottom of the funnel.

Select the Right Tooling: Choose the appropriate tooling for free-flow and non-free-flow products.

Correct Auger Position: Ensure the auger is correctly positioned within the funnel.

Conclusion

Investing in a servo motor auger filler can significantly improve your packaging line's speed, accuracy, and versatility. Whether you're dealing with high-speed bagging operations or require precise control for different products, a servo motor offers a reliable and efficient solution. If you have any questions or want to explore our Image 2500 servo motor auger filler, please give us a call. We're here to help you find the perfect fit for your packaging needs.

Copyright © 2024 ImageFillers Inc. All rights reserved.

United States

Facebook

Instagram

X

LinkedIn

Youtube