Watch Image Fillers

Machines In Action.

Watch videos of our Image 3500 transformation played to the Rocky movie soundtrack. Other videos include the perfect solution machine filling cannabis powder and more auger demos.

Explore our filling and packaging machines.

The Ultimate Guide to a Fully Automated Packaging Line for Powder Products

The Ultimate Guide to a Fully Automated Packaging Line for Powder Products

In the fast-paced world of manufacturing, efficiency and precision are paramount. For businesses dealing with powder products, a fully automated packaging line can significantly enhance productivity and ensure consistent product quality. But what exactly should a fully integrated packaging line include? Let’s delve into the essential components and their roles in creating a seamless packaging process.

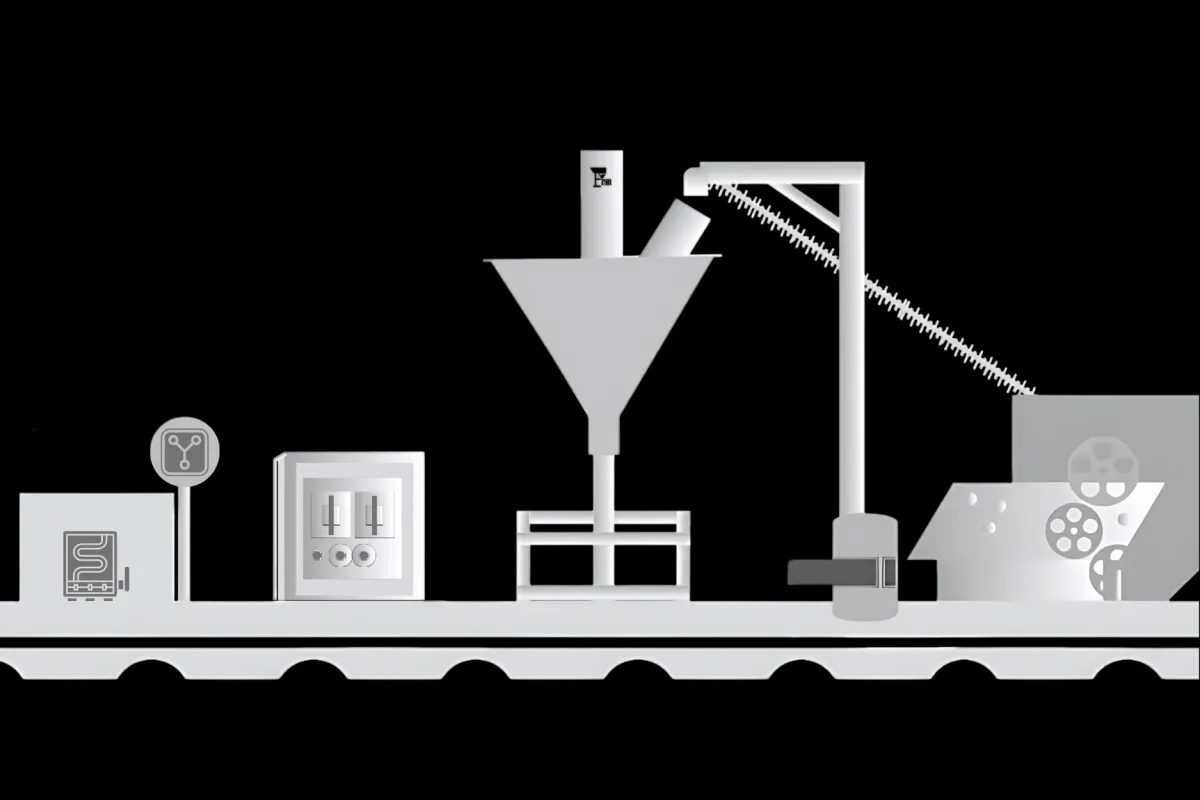

Key Components of a Fully Integrated Packaging Line

Unscrambler The journey begins with the unscrambler, a critical machine that sorts and aligns bottles before feeding them onto the conveyor. This ensures that each bottle is correctly oriented, reducing downtime and preventing jams further down the line.

Labeler Once the bottles are aligned and moving along the conveyor, the labeler takes over. This machine accurately applies labels to each bottle, ensuring that your branding and product information are prominently displayed.

Screw Conveyor The screw conveyor plays a pivotal role in transporting the powder product from storage to the auger filler. It automates the feeding process, ensuring a steady supply of product for filling.

Auger Filler The heart of the operation is the auger filler. This precision instrument dispenses the exact amount of powder into each bottle. Key factors to ensure its optimal performance include:

Maintaining Proper Product Levels: Always keep the correct amount of product in the hopper to avoid inconsistencies.

Agitation Blade: Use an agitation blade to prevent the powder from clumping and ensure smooth flow.

Spinner Plate Angle: The spinner plate should be at a 45° angle to the bottom of the funnel for free-flowing augers.

Correct Tooling: Choose the right tooling based on whether the powder is free-flowing or non-free-flowing.

Auger Positioning: Ensure the auger is correctly positioned within the funnel for precise dispensing.

Capper After filling, the next step is sealing. The capper securely places caps on each bottle, protecting the contents from contamination and spillage.

Coder The coder adds essential information such as batch numbers and expiration dates to the bottles. This step is crucial for traceability and compliance with industry regulations.

Accumulator Finally, the accumulator collects the filled, labeled, and capped bottles off the conveyor, organizing them for packaging or further processing.

Why Choose a Fully Automated Packaging Line?

Investing in a fully automated packaging line offers numerous benefits:

Increased Efficiency: Automation reduces the need for manual intervention, speeding up the packaging process.

Consistency: Automated systems ensure that each bottle is filled, labeled, capped, and coded accurately, maintaining product quality.

Cost Savings: By minimizing waste and reducing labor costs, automation can lead to significant savings over time.

Contact us today to learn more and get started on enhancing your production efficiency.

By implementing a fully automated packaging line, you can take your powder product manufacturing to the next level, ensuring precision, efficiency, and quality at every step. Don’t wait – upgrade your operations with Imagefillers and see the difference automation can make!

Copyright © 2024 ImageFillers Inc. All rights reserved.

United States

Facebook

Instagram

X

LinkedIn

Youtube