Playlists

Maintenance and Parts Instructionals

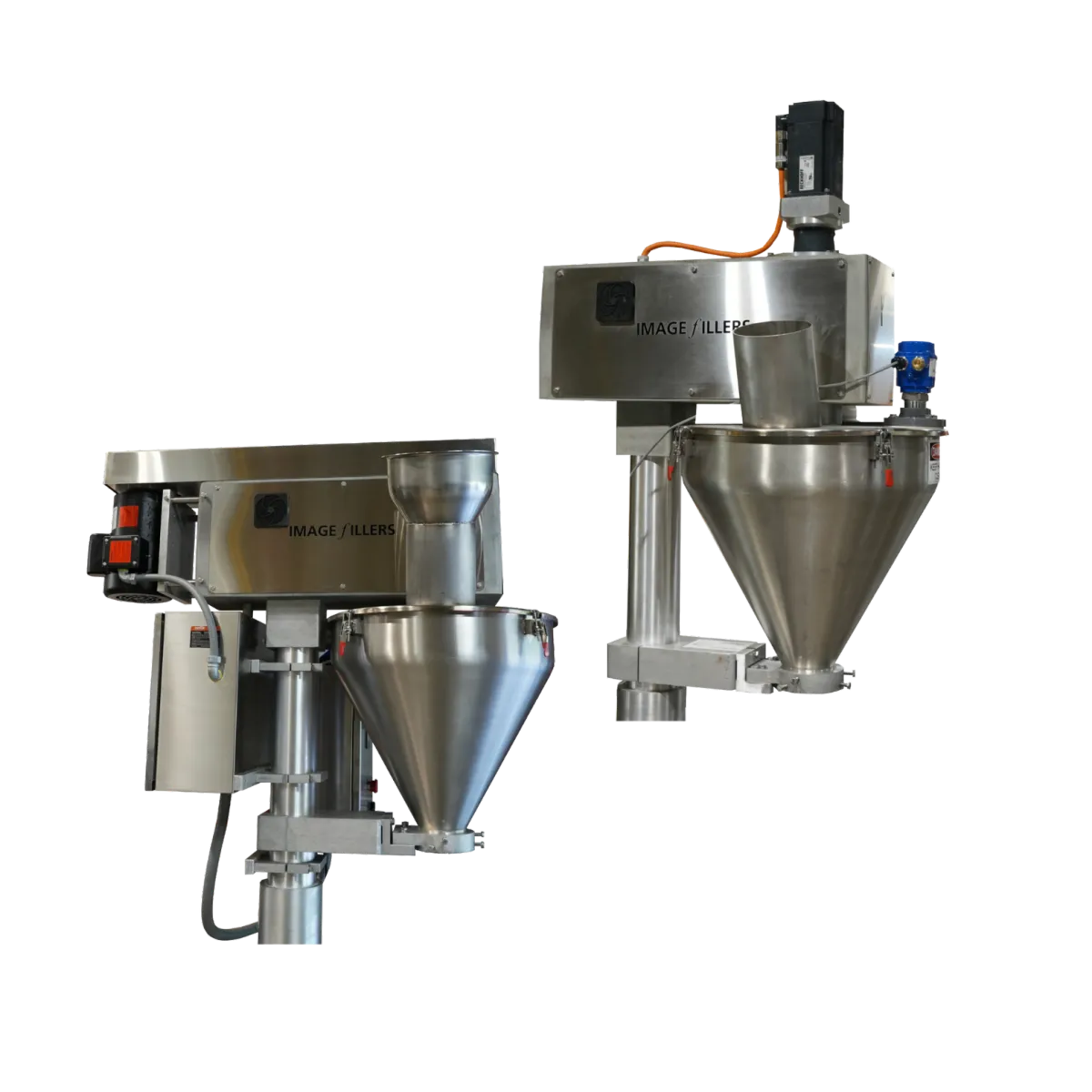

Watch a video or read an article to learn about auger fillers

How to - Proper Distance Between Spinner Plate and Funnel

How to Set the Correct Distance from the Spinner Plate to the Funnel for Accurate Filling

Setting the correct distance between the spinner plate and the bottom of the funnel is crucial for ensuring accurate fills in free-flow machines.

Follow these steps to adjust the spinner plate:

Steps:

Loosen the auger shaft bolt by reaching into the hopper.

Adjust the spinner plate by pulling the auger shaft up or down until the spinner plate forms a 45-degree angle with the bottom of the funnel (known as the angle of repose).

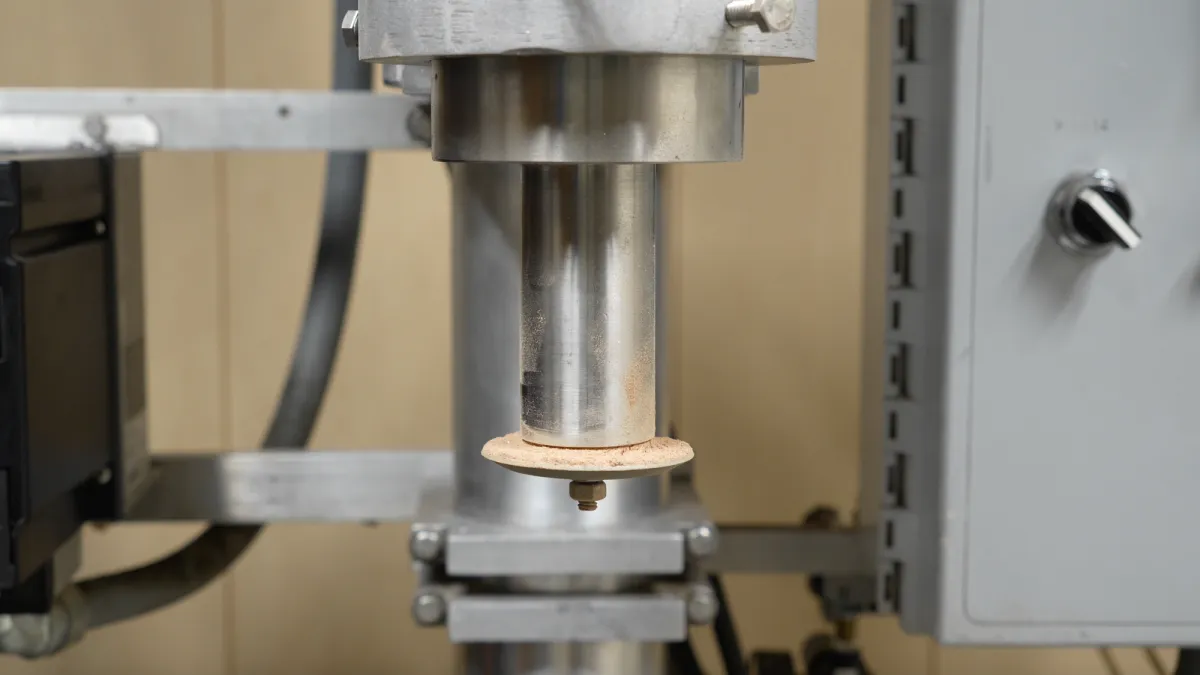

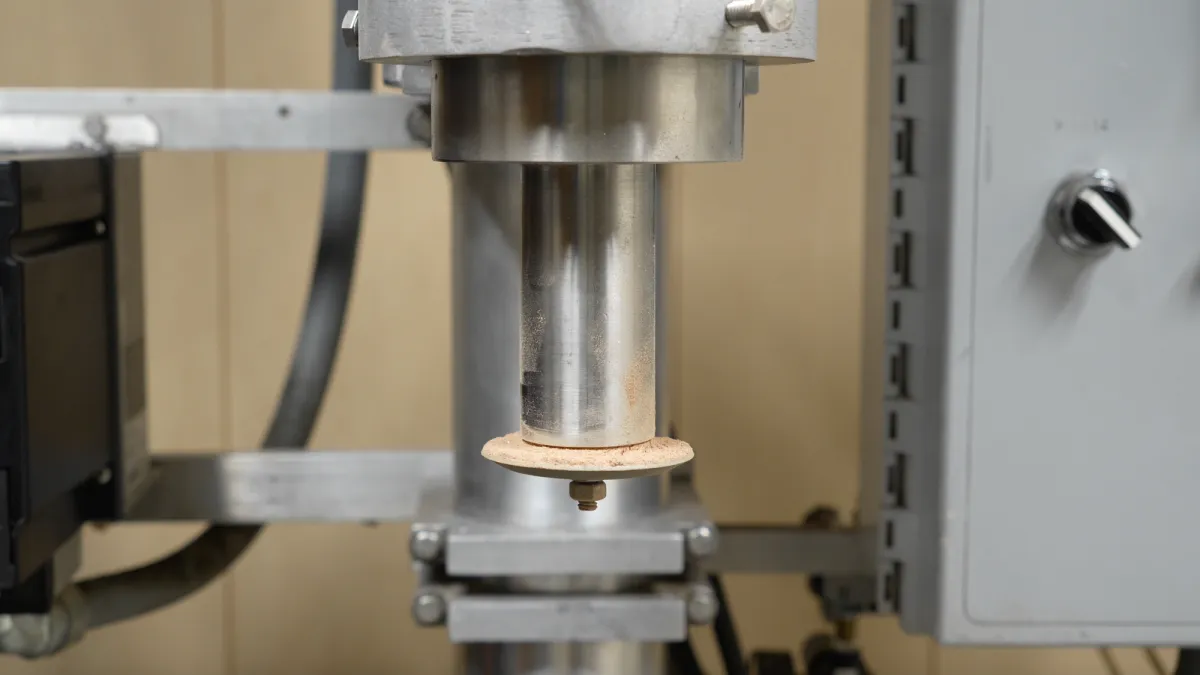

This is what the spinner plate should look like at a 45 degree angle.

This is too high.

This is too low.

Once the correct angle is set, tighten the auger shaft bolt.

Why 45 Degrees?

The 45-degree angle is essential for accurate filling. If the angle is off, your servo motor auger filler won't deliver the precision it’s designed for.

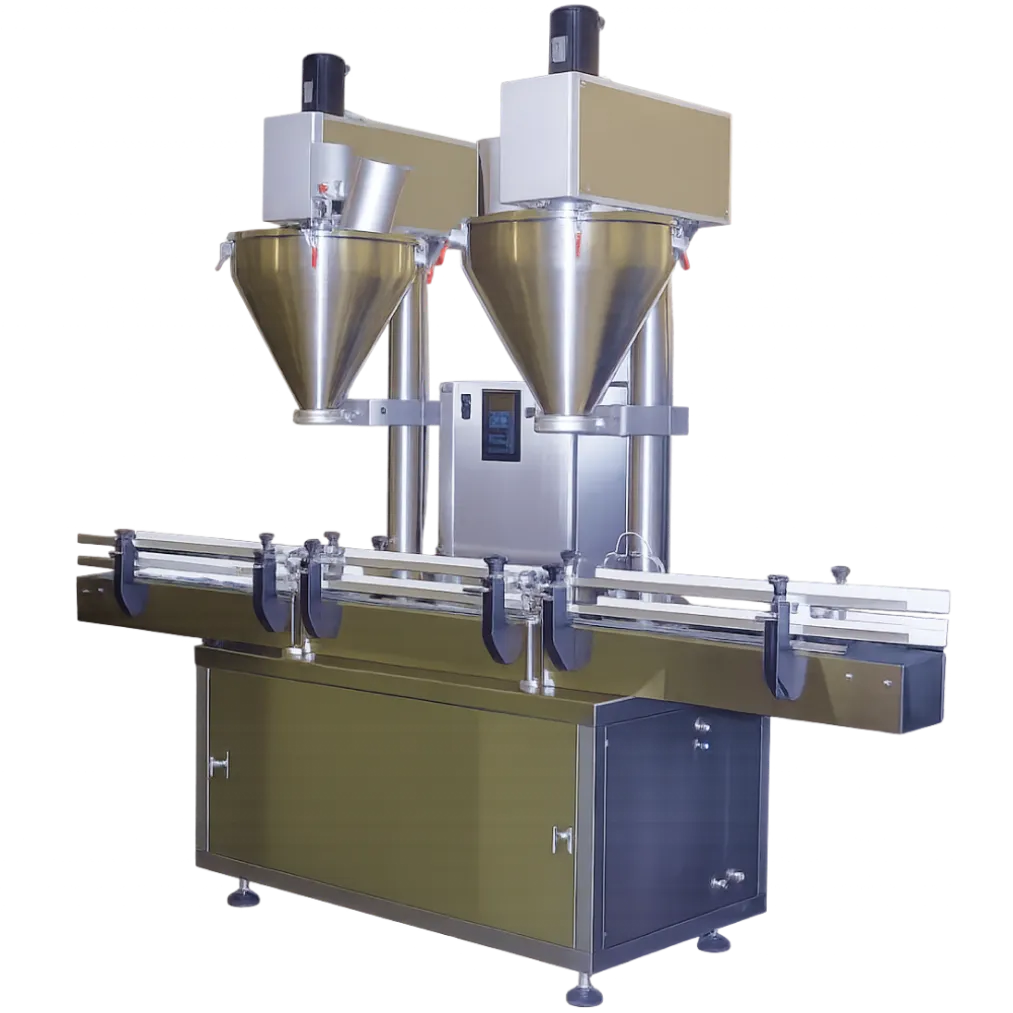

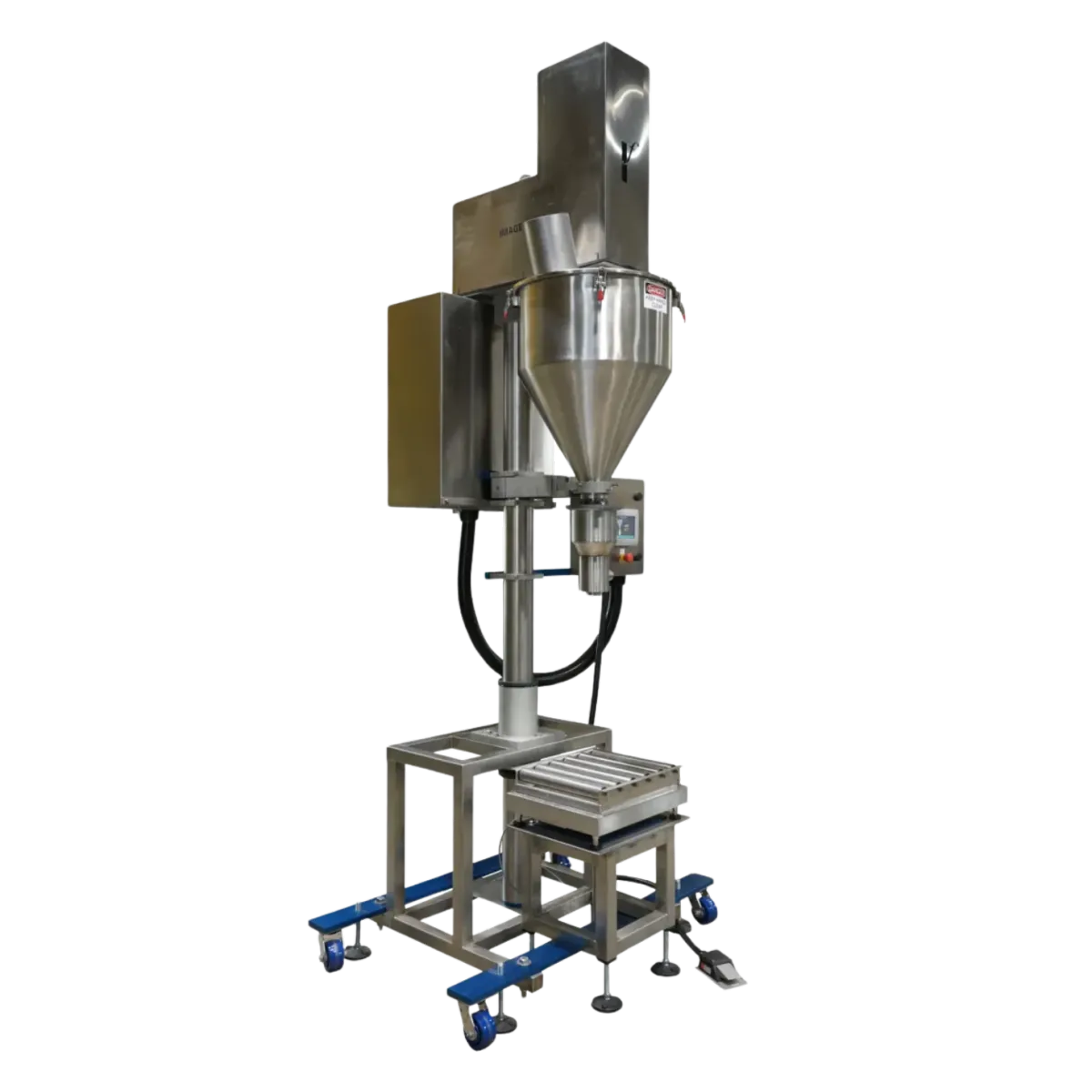

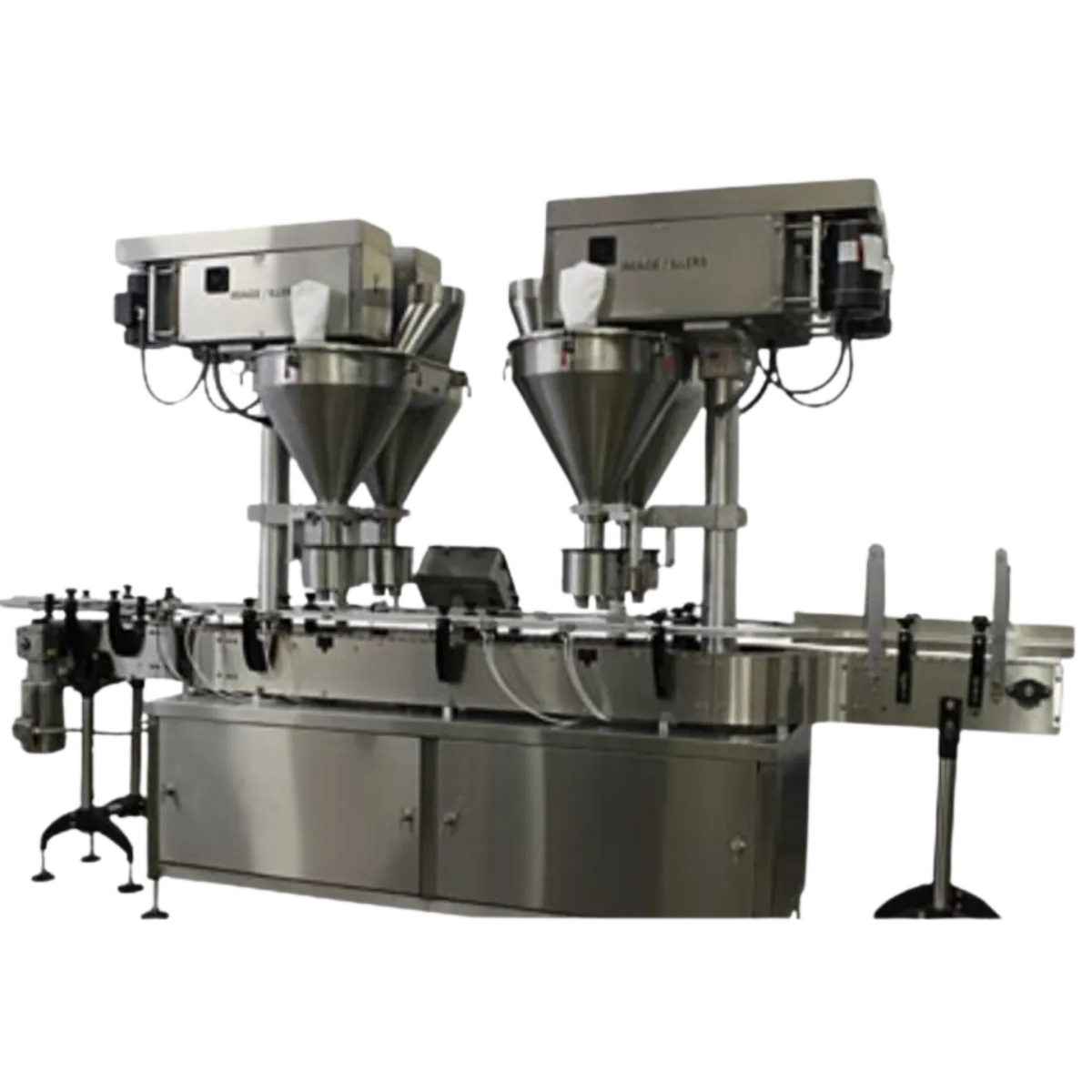

View our machine lineup at: ImageFillers.com/product-page

Maintenance and Parts Instructionals

Watch a video or read an article to learn about auger fillers

Setup videos

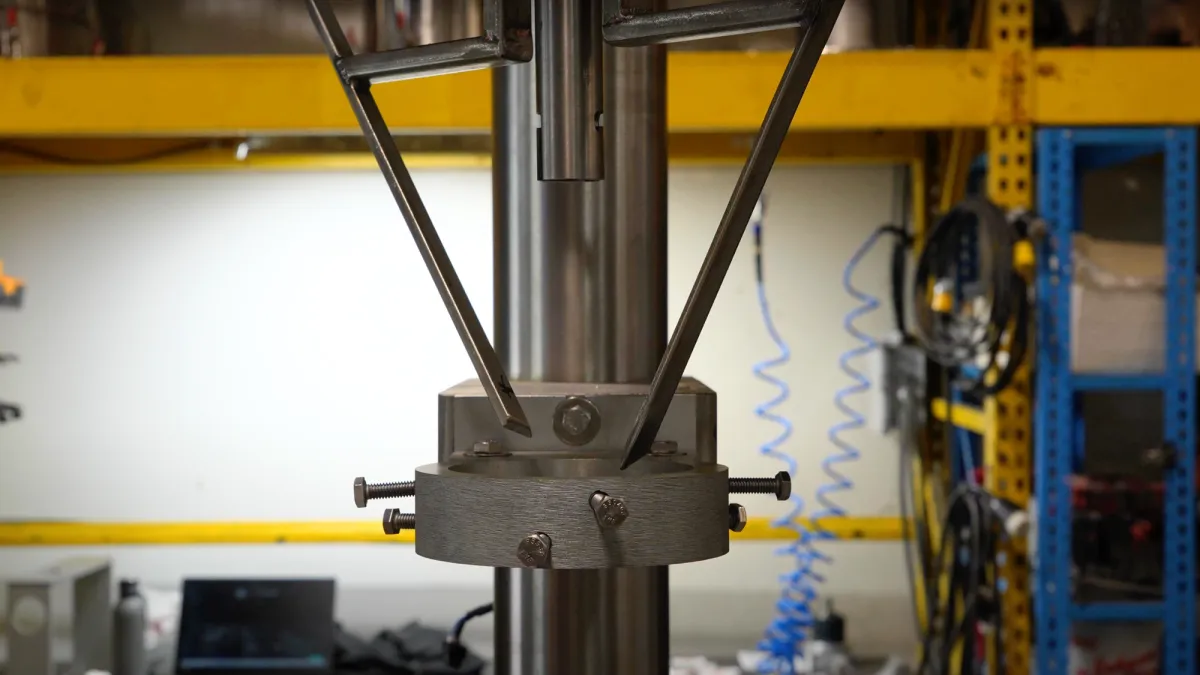

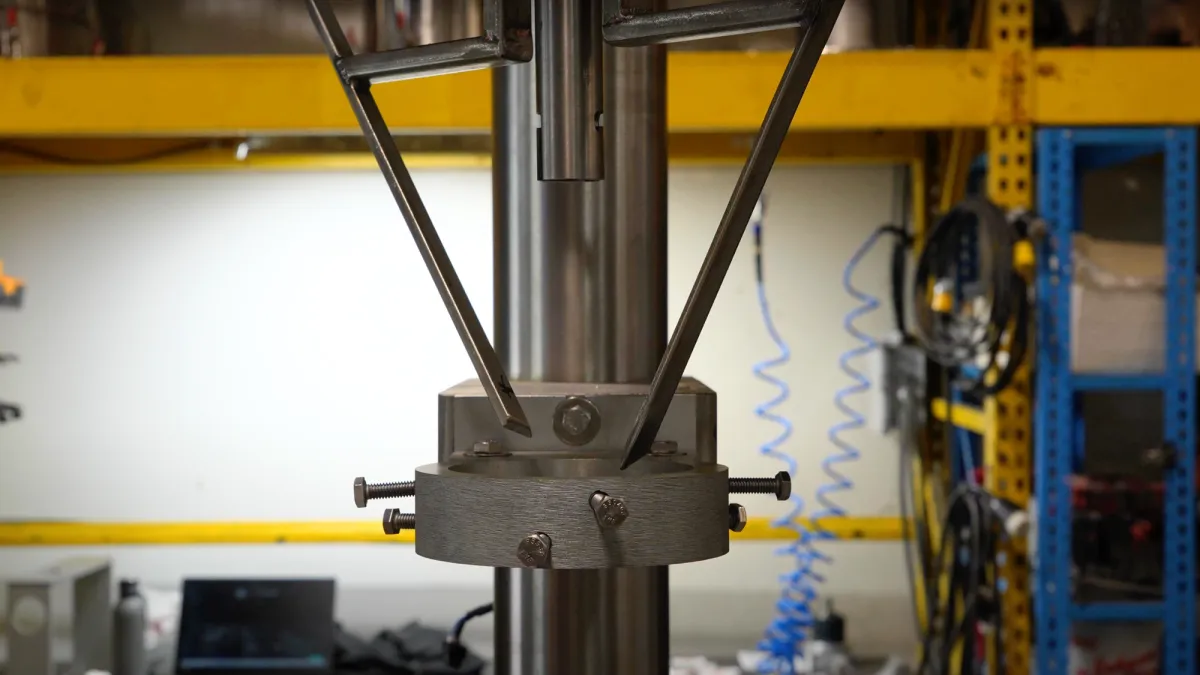

Spinner plate adjustment

Auger alignment

Non free flow auger adjustment

Setup videos

Spinner plate adjustment

Auger alignment

Non free flow auger adjustment

Find repair tooling

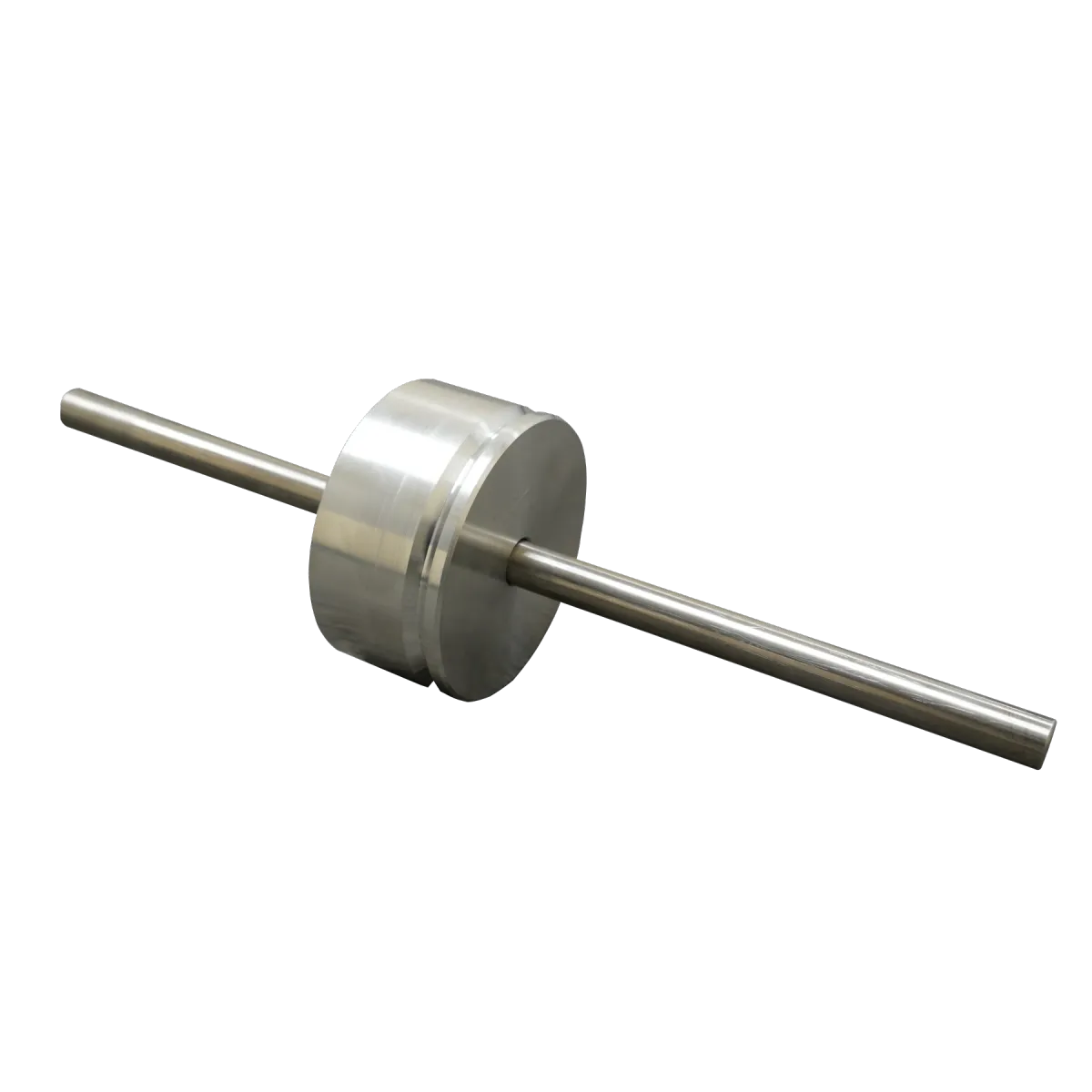

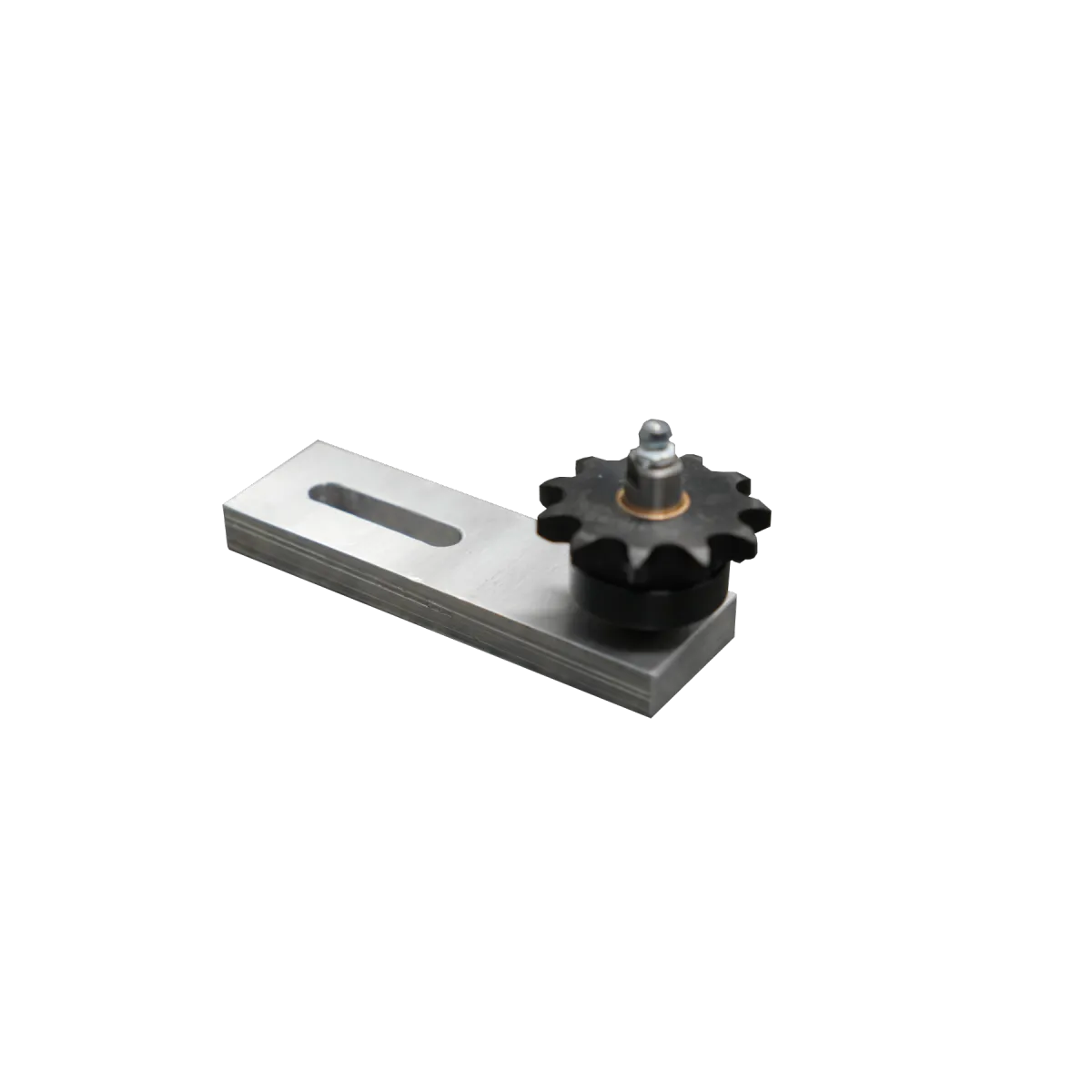

Auger alignment tool

Auger alignment

Hopper ring

Auger alignment

Disassembly & Repair Instruction

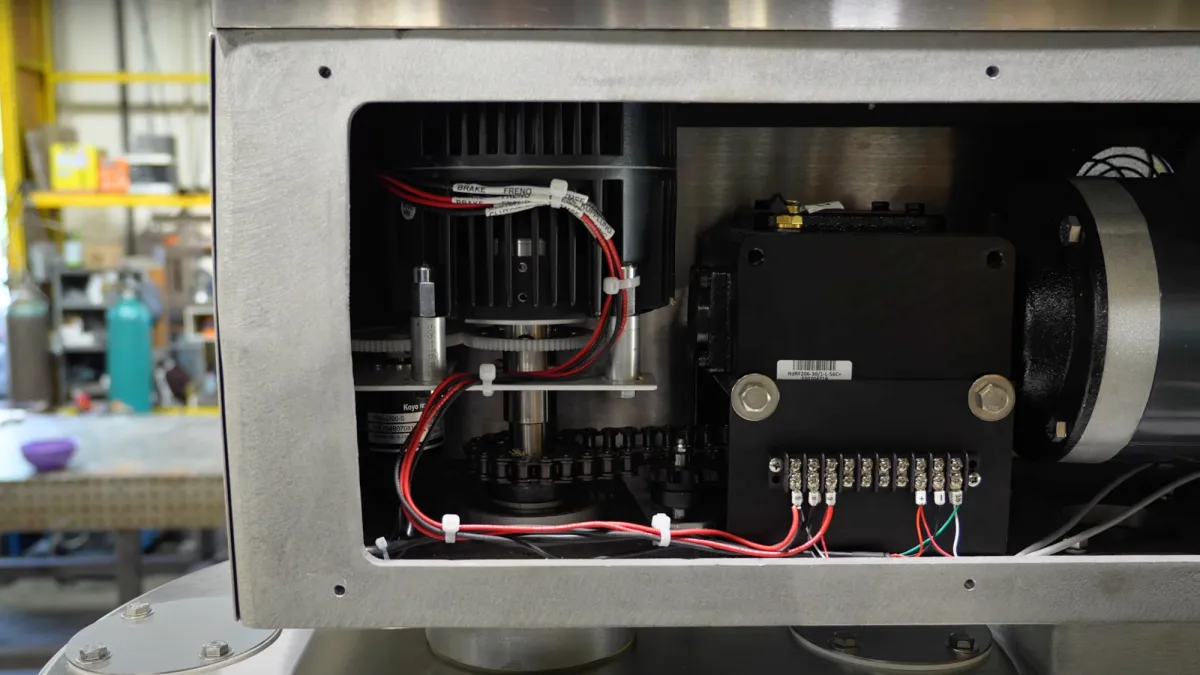

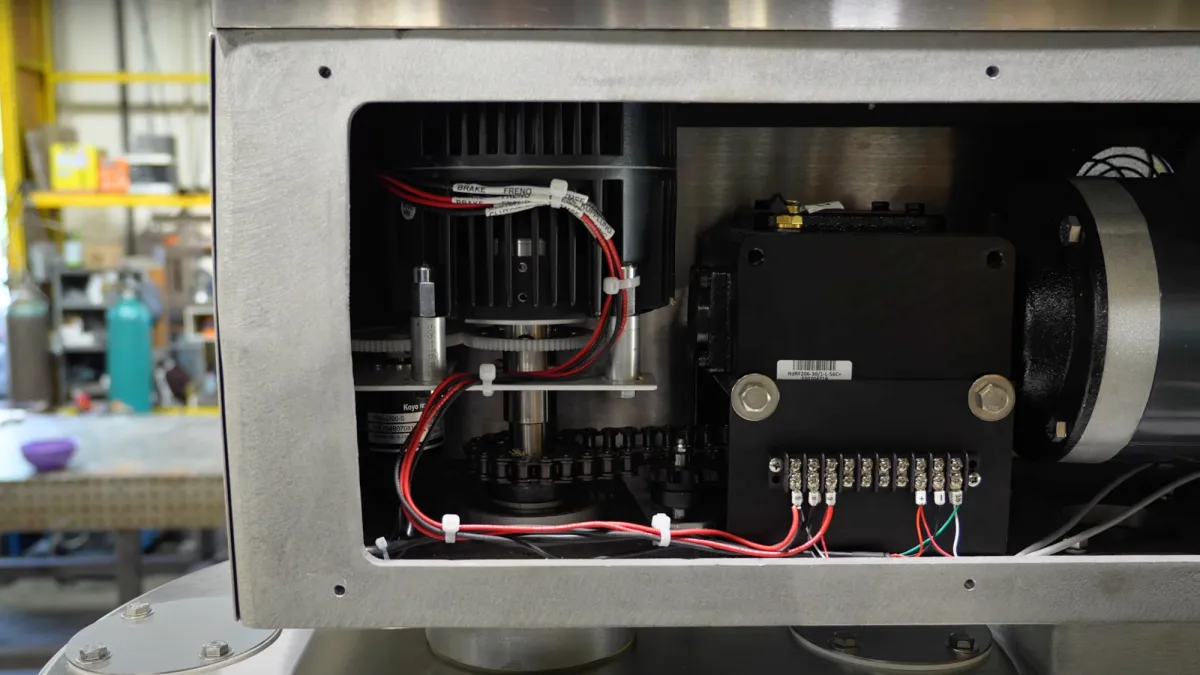

Slow speed bearing housing replacement

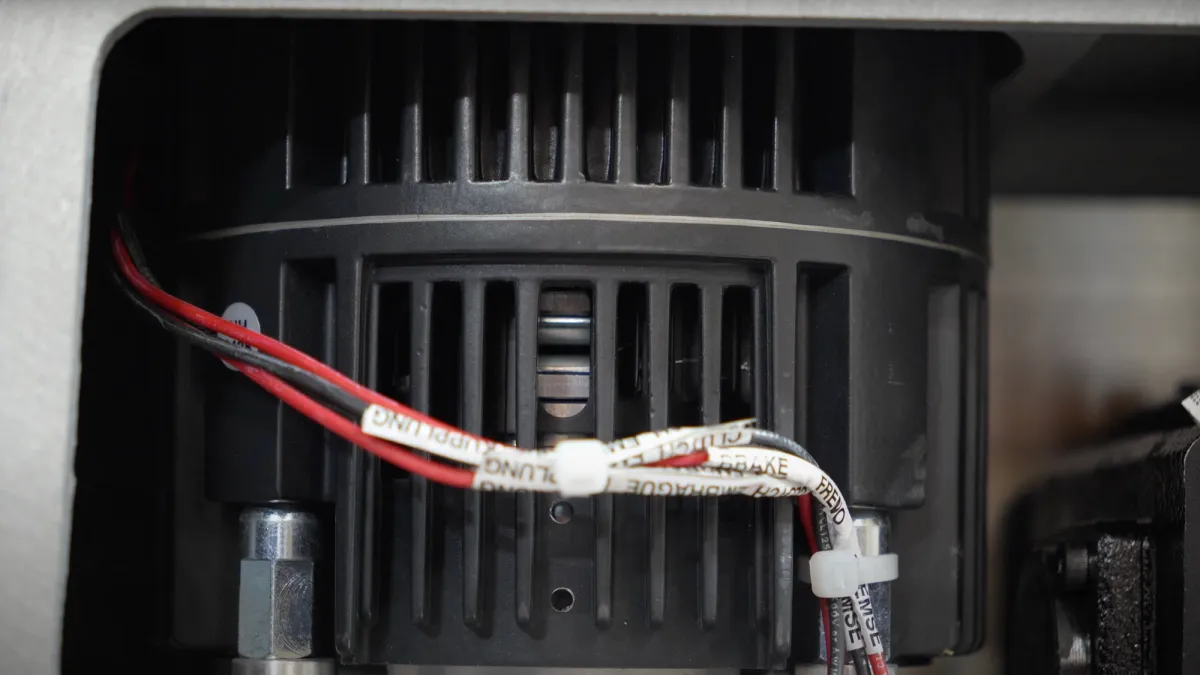

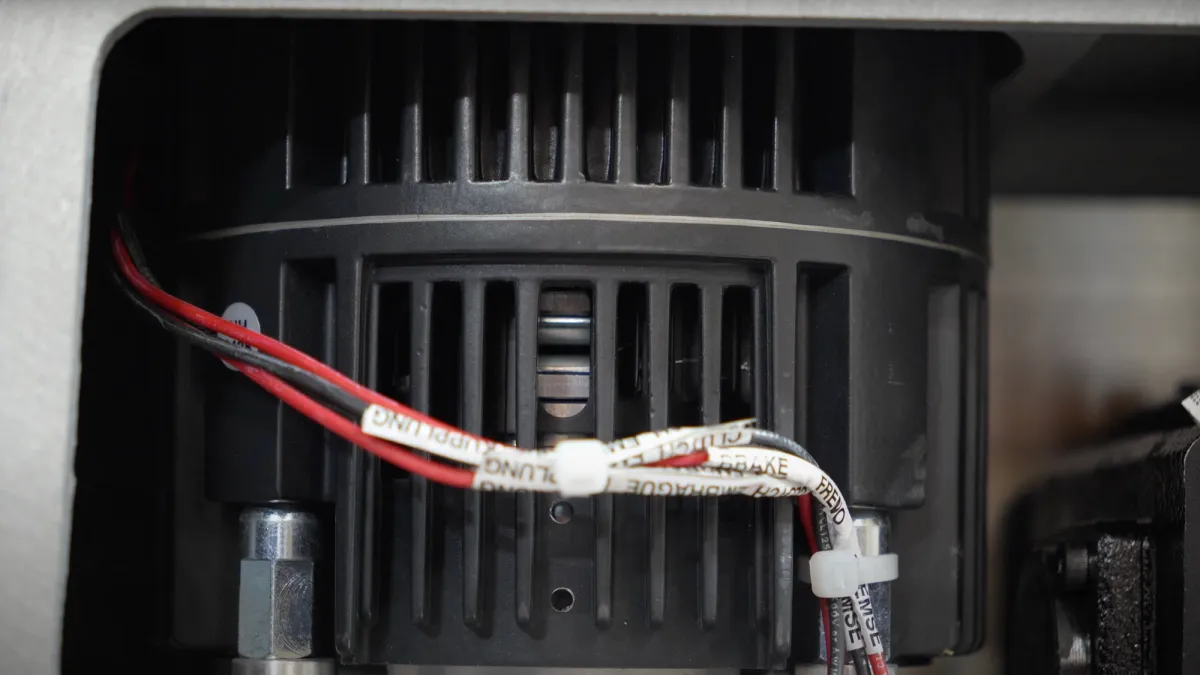

Clutch brake motor replacement

Non free flow auger filler disassembly

Fix your clutch brake armature plates

Disassembly Instruction

Slow speed bearing housing replacement

Clutch brake motor replacement

Non free flow auger filler disassembly

Fix your clutch brake armature plates

Find disassembly parts

Slow speed bearing housing

Clutch brake motor

Prying irons

Idler assembly

PLC operation Instruction

Allen Bradley PLC instructions

Mitsubishi PLC instructions

PLC operation Instruction

Allen Bradley PLC instructions

Mitsubishi PLC instructions

Download PLC Manuals

Allen Bradley PLC Manual

Mitsubishi PLC Manual

Filler & product information

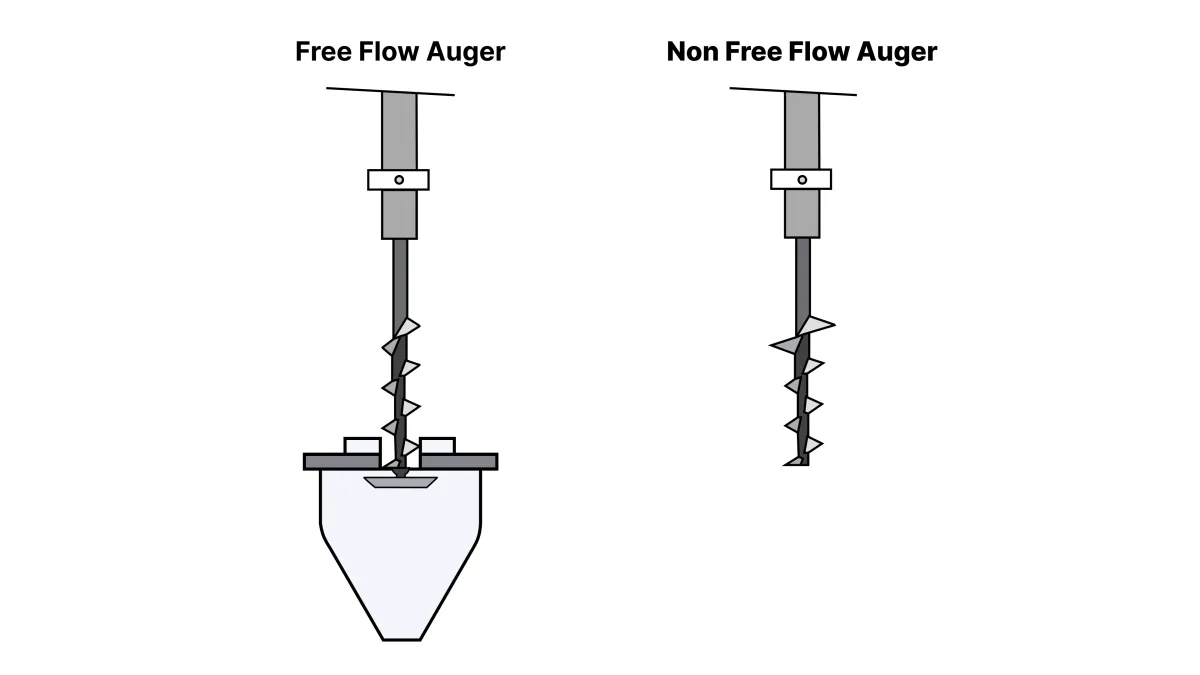

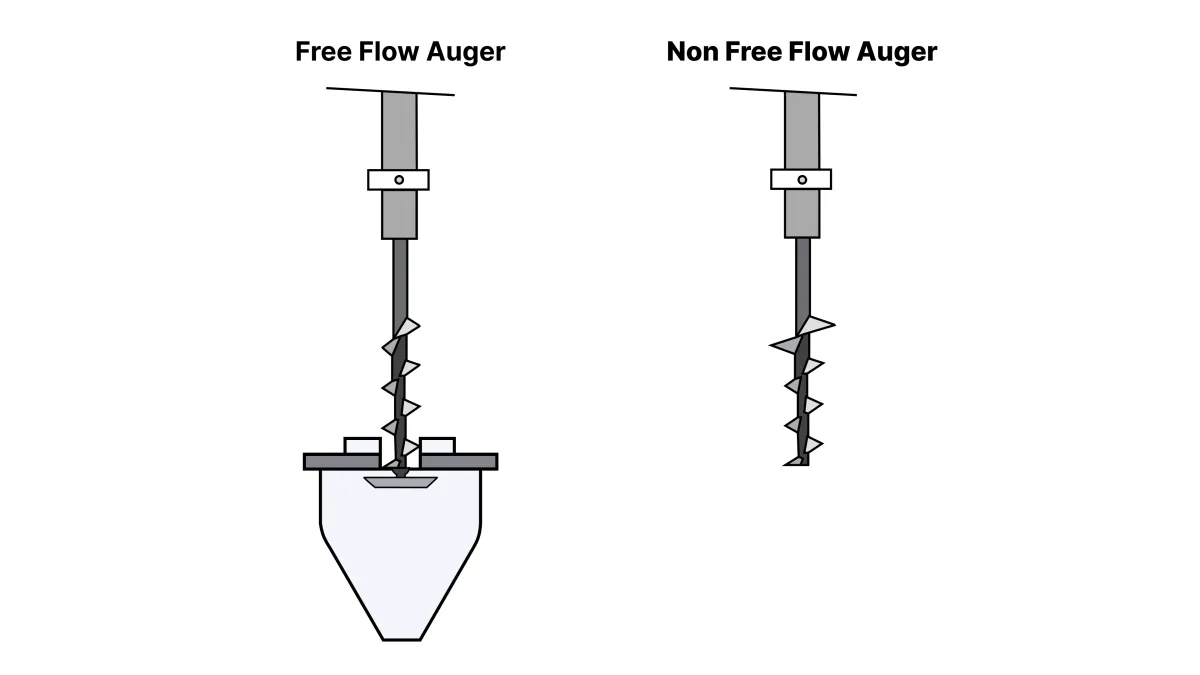

Determining free flow or non free flow

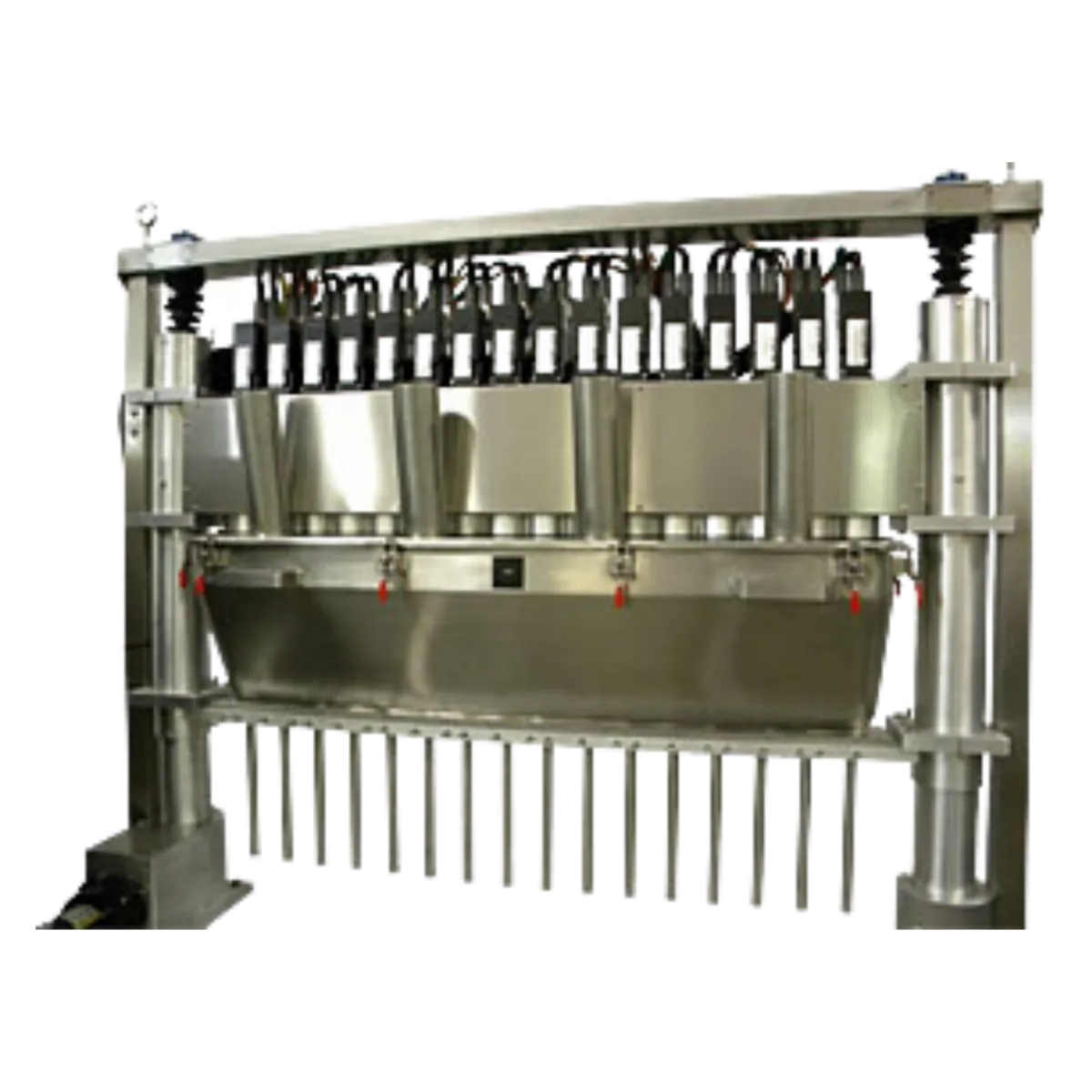

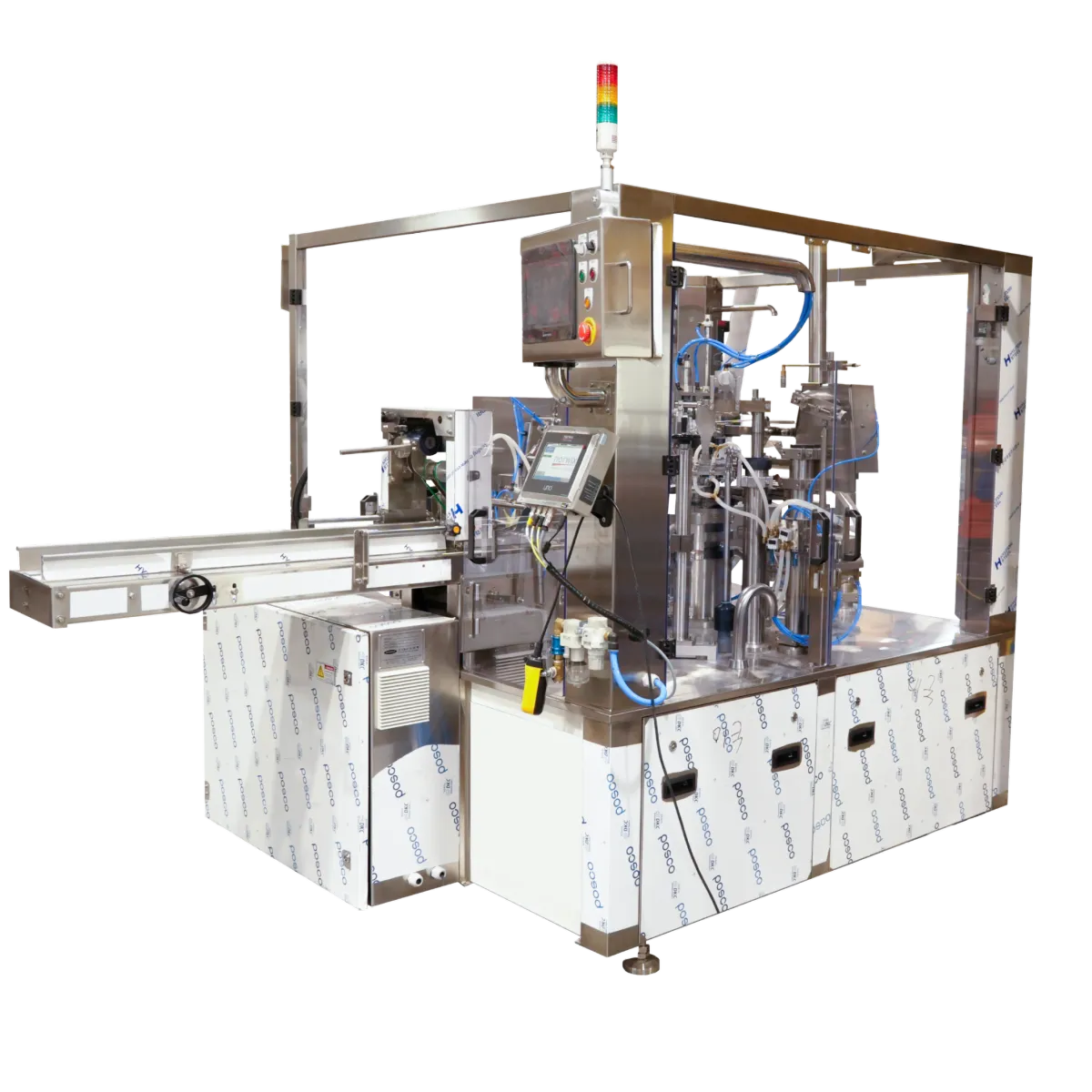

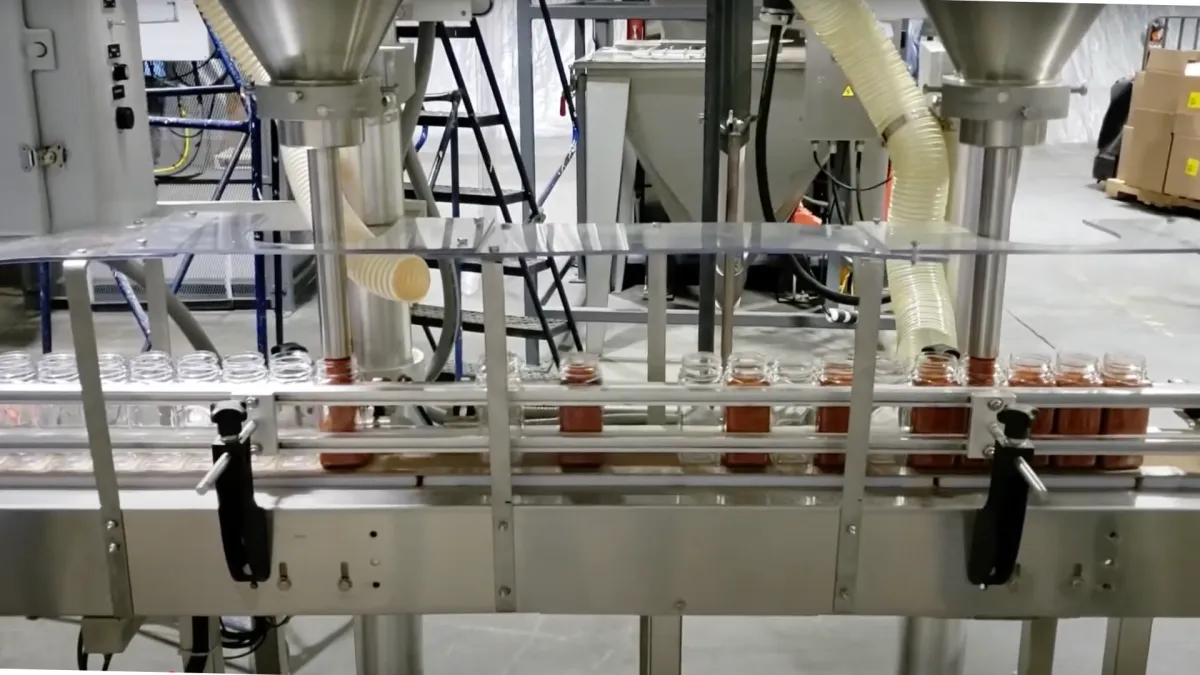

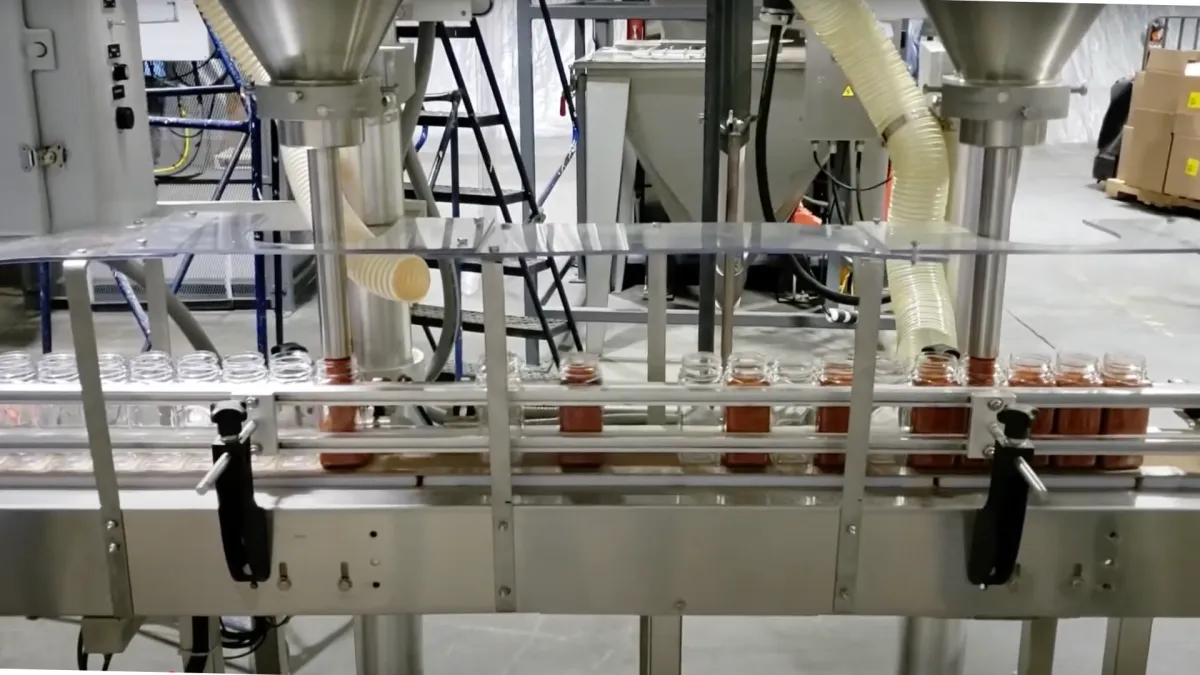

Fully automated bottling line components

Clutch brake or servo drive motor

Automation cost breakdown

Filler & product information

Determining free flow or non free flow

Fully automated bottling line

Clutch brake or servo drive motor

Automation cost breakdown

Contact

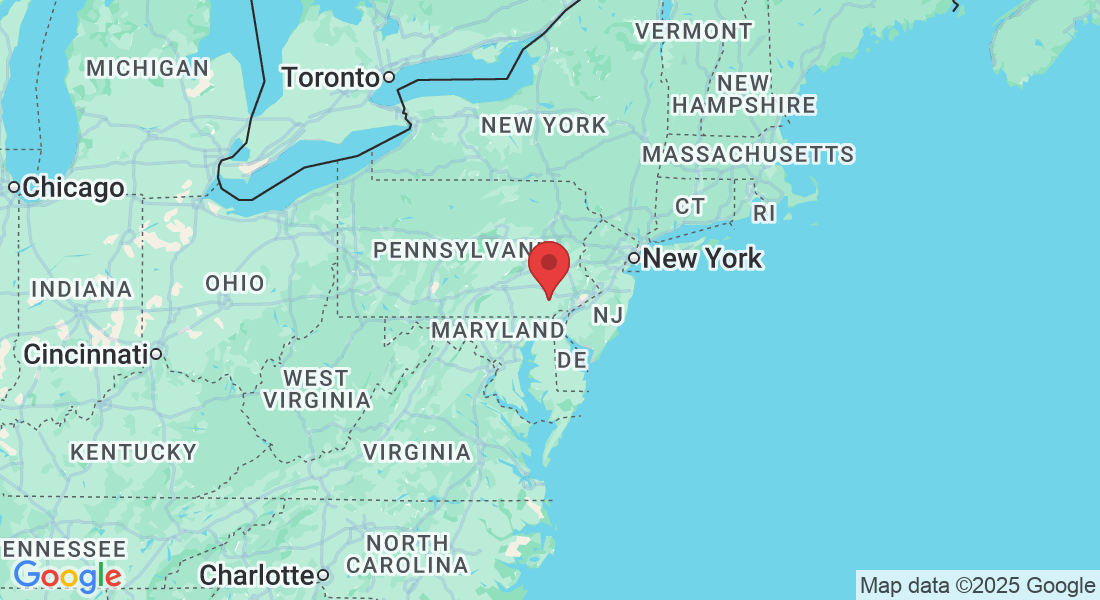

Hours: 9 AM - 5 PM

735 Fox Chase Rd # 111, Coatesville, PA 19320

(610) 466-1440

To purchase a machine, call (610) 466-1440 or email [email protected]

Image Fillers © 2025

Made in the United States