Playlists

Maintenance and Parts Instructionals

Watch a video or read an article to learn about auger fillers

The Story of Image Fillers

Image Fillers: The Beginning

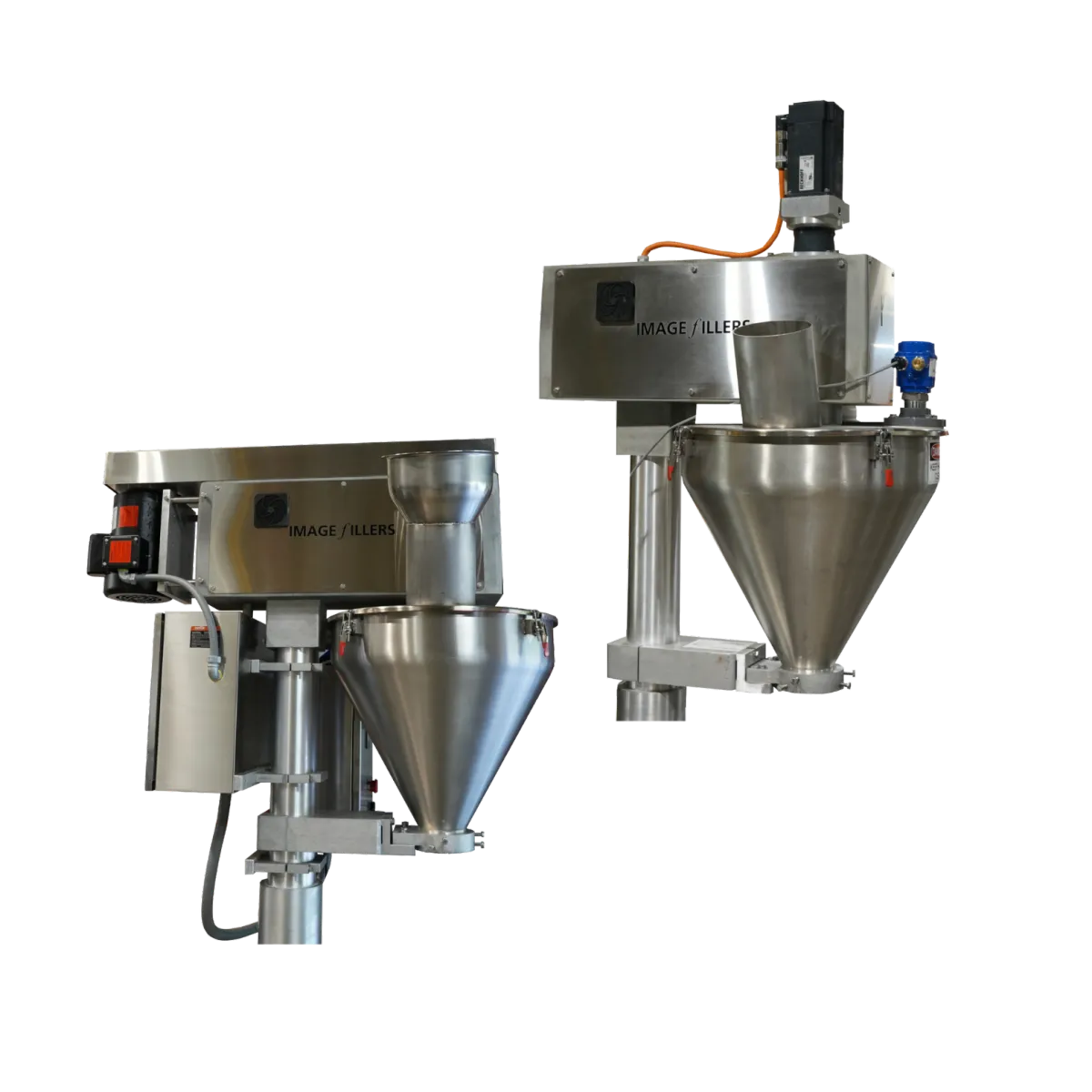

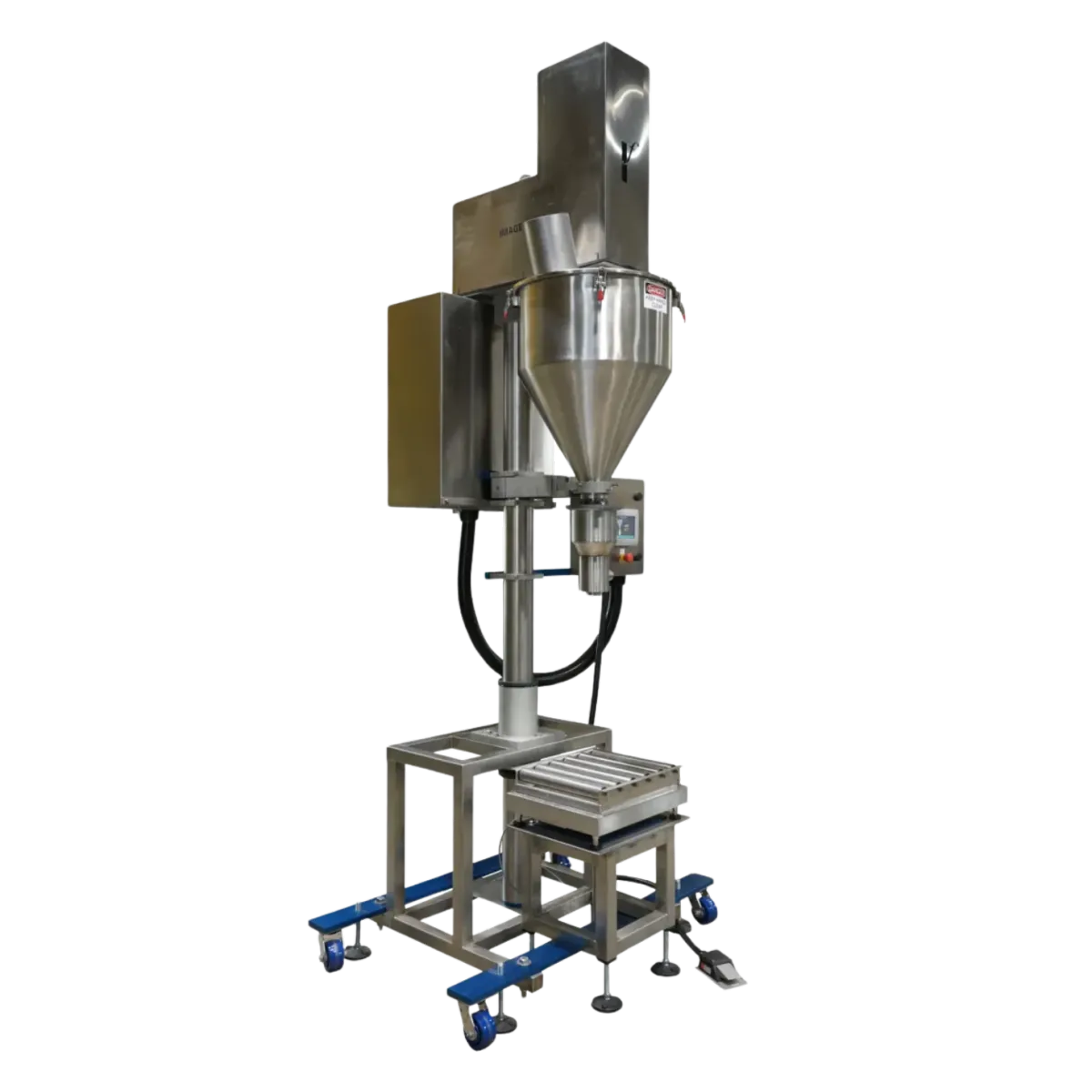

In 1996, Mike Kelly Sr. founded Image Fillers Inc. with a simple yet ambitious goal: to breathe new life into old auger fillers. He began by refurbishing used auger fillers to near-new condition. His hands-on approach to rebuilding these machines laid the foundation for what would become a pioneering force in the packaging industry.

Building Something New

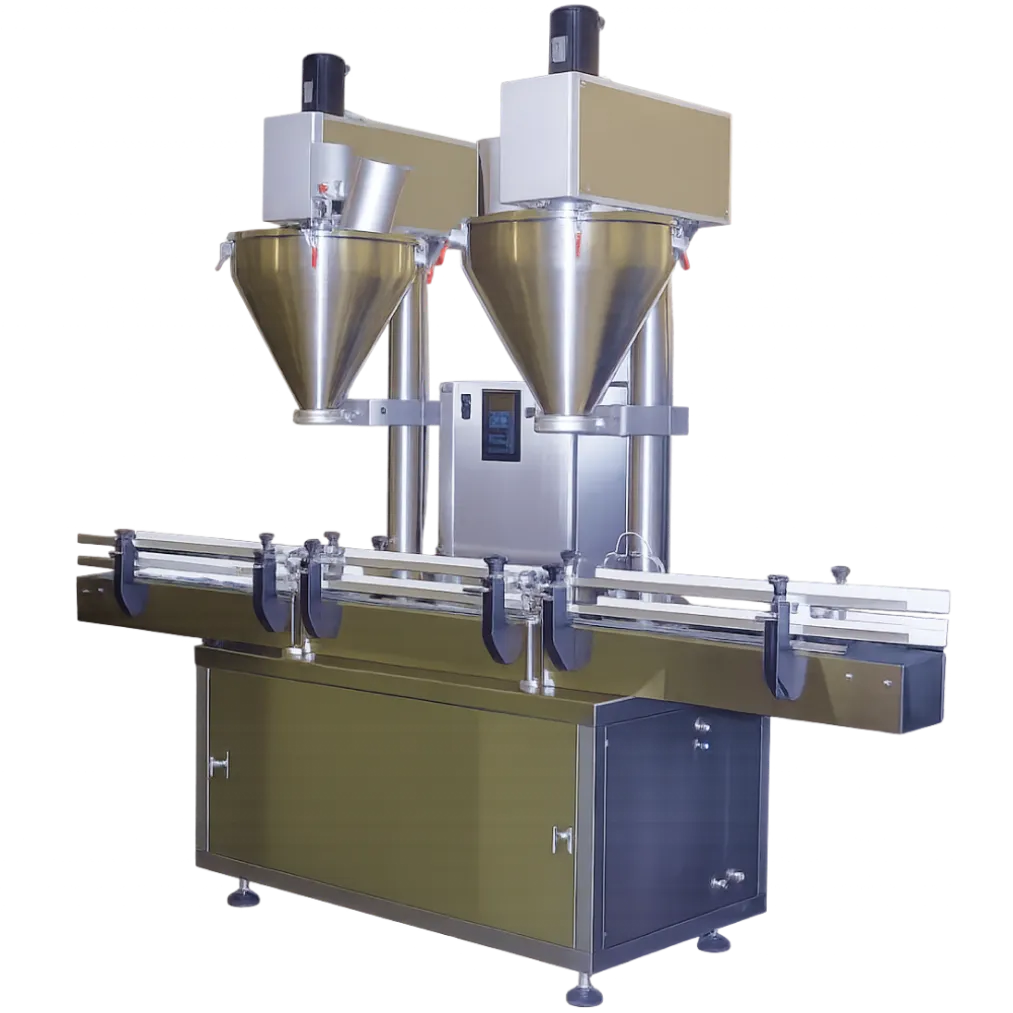

By 1999, Mike Kelly Sr. had shifted from refurbishing machines to creating new ones. Drawing inspiration from the best features of various manufacturers, he introduced his own innovations that set Image Fillers apart. He was one of the first in the industry to offer anodized head castings, stainless steel parts and frames, and height-adjustable frames. One of his key decisions was to design non-proprietary machines that used readily available off-the-shelf parts, making maintenance and upgrades easy for customers.

Expanding into Automation

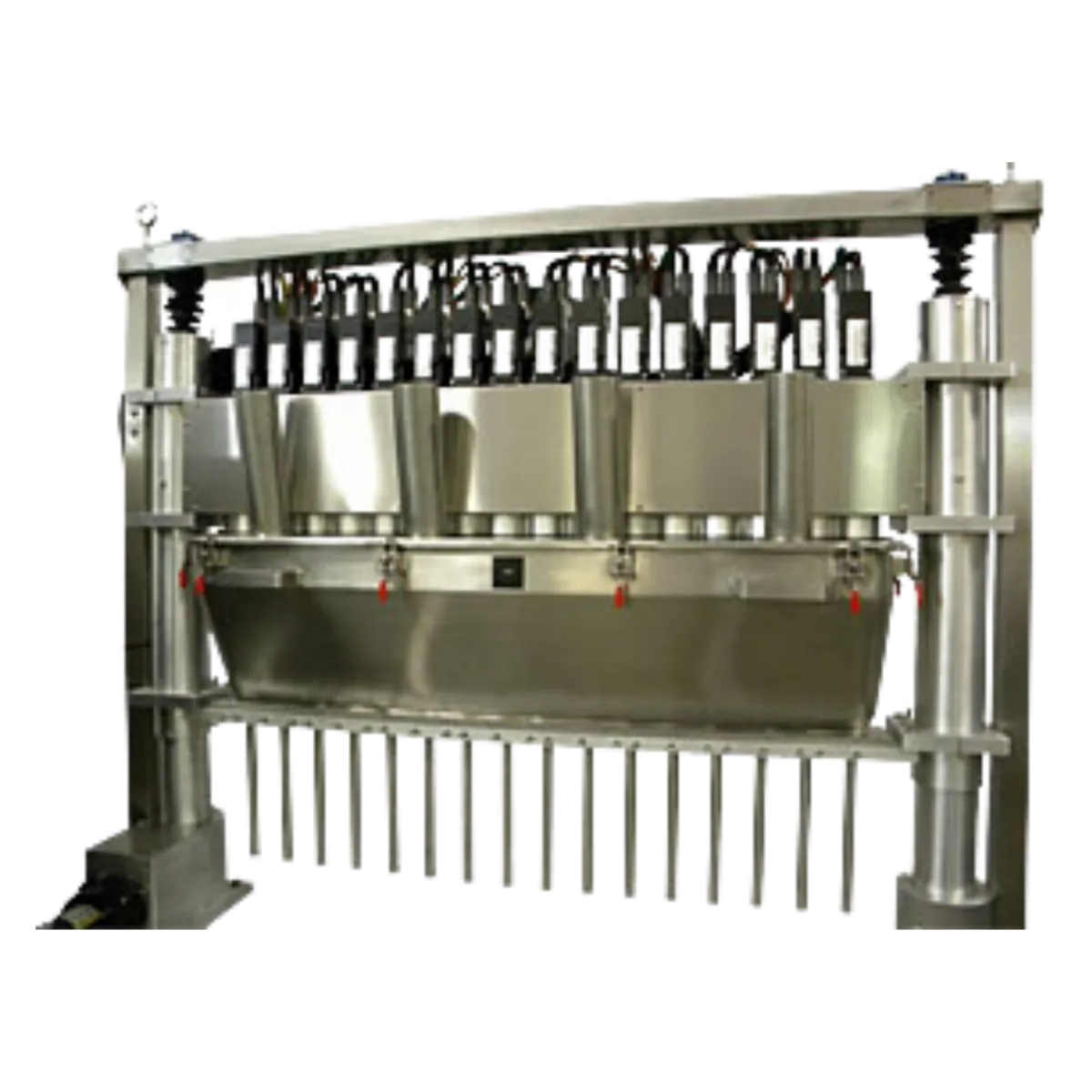

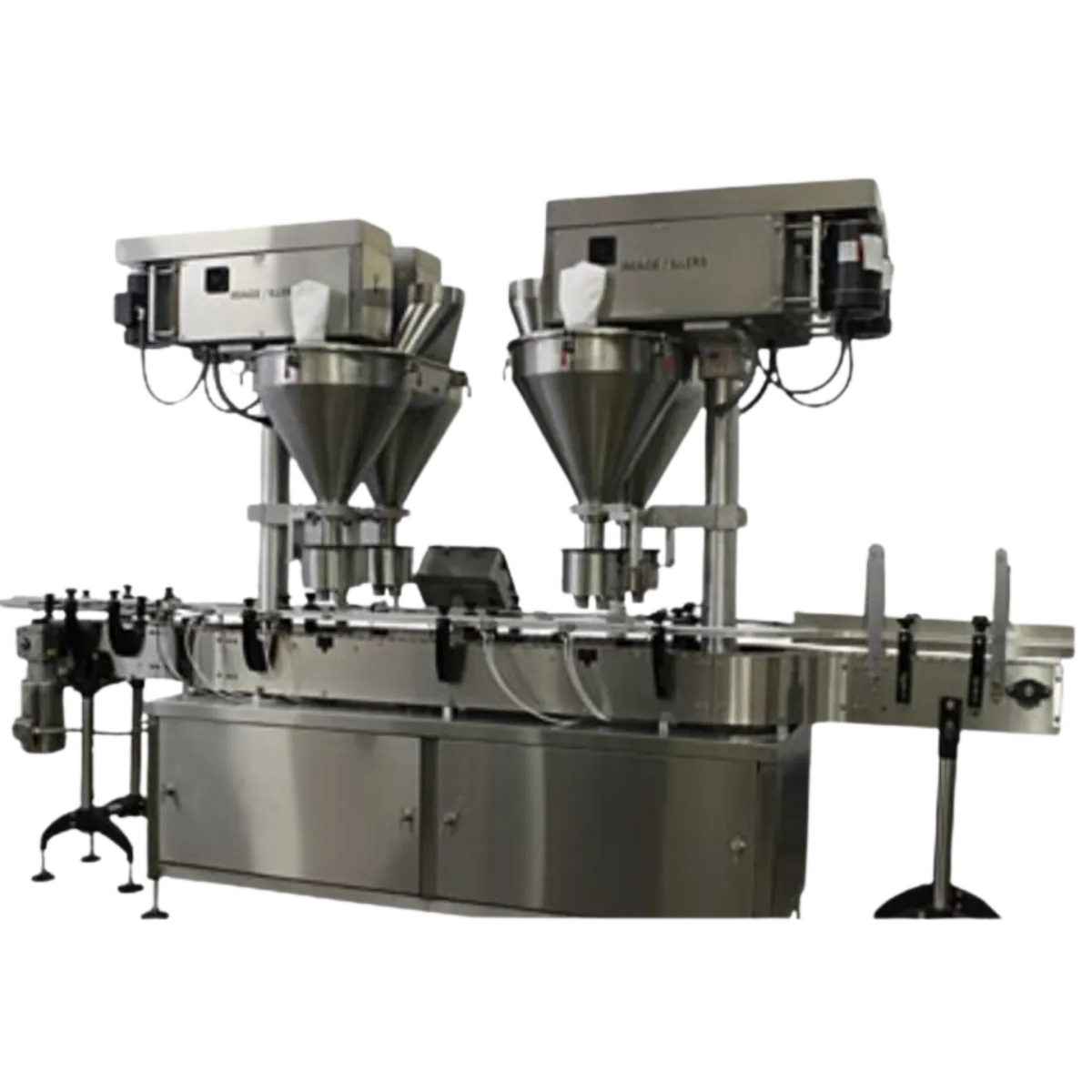

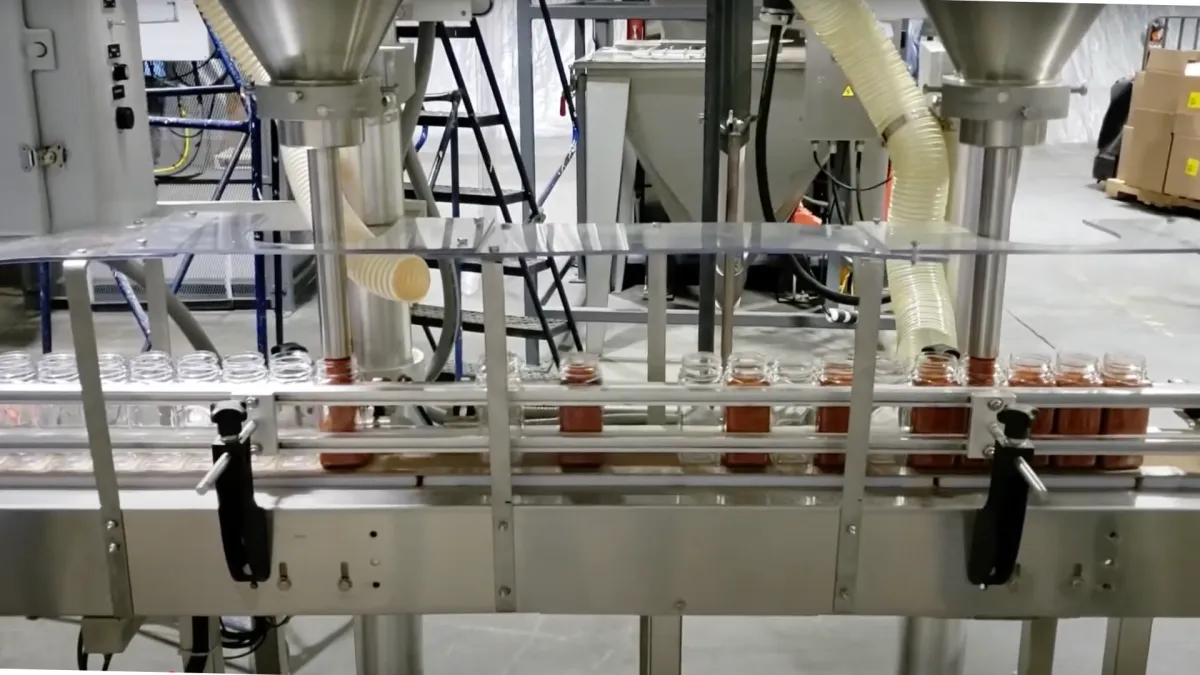

In the early 2000s, Image Fillers began building fully automatic machines. The company’s product range grew, with offerings from semi-automatic fillers to high-speed rotary fillers capable of filling hundreds of containers per minute. This shift marked the beginning of a new era for Image Fillers, positioning the company as an industry leader in packaging technology.

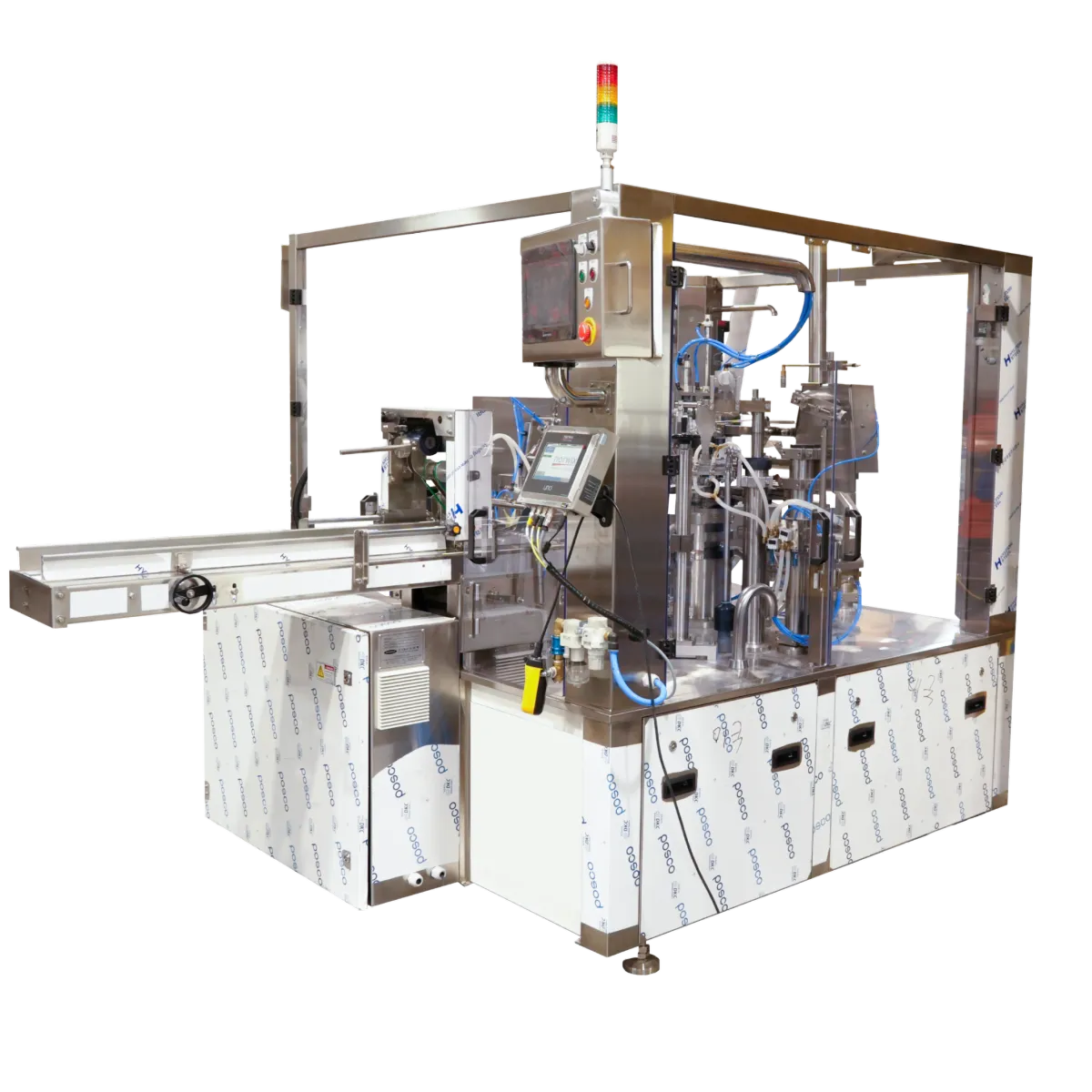

Fully Integrated Packaging Lines

By 2010, Image Fillers had introduced fully integrated packaging lines that included not just auger fillers but also supporting equipment like unscramblers, labelers, screw conveyors, cappers, coders, and accumulators. The ability to provide a complete packaging solution set the company apart and made Image Fillers a trusted partner for companies seeking efficiency and innovation.

Image Fillers Today

After 28 years in business, Image Fillers continues to be recognized as a leader in the packaging industry. With a comprehensive range of fully automated systems, from high-speed rotary fillers to integrated packaging lines, Image Fillers has helped businesses across various industries enhance their operational efficiency. The company’s commitment to innovation, quality, and customer service remains as strong as it was when Mike Kelly Sr. first started restoring old auger fillers in 1996.

Whether you’re looking for a semi-automatic filler or a fully integrated packaging line, Image Fillers has the expertise and equipment to meet your needs. Contact us today to learn more about how we can help streamline your packaging operations.

View our product line today at: imagefillers.com/product-page

Maintenance and Parts Instructionals

Watch a video or read an article to learn about auger fillers

Setup videos

Spinner plate adjustment

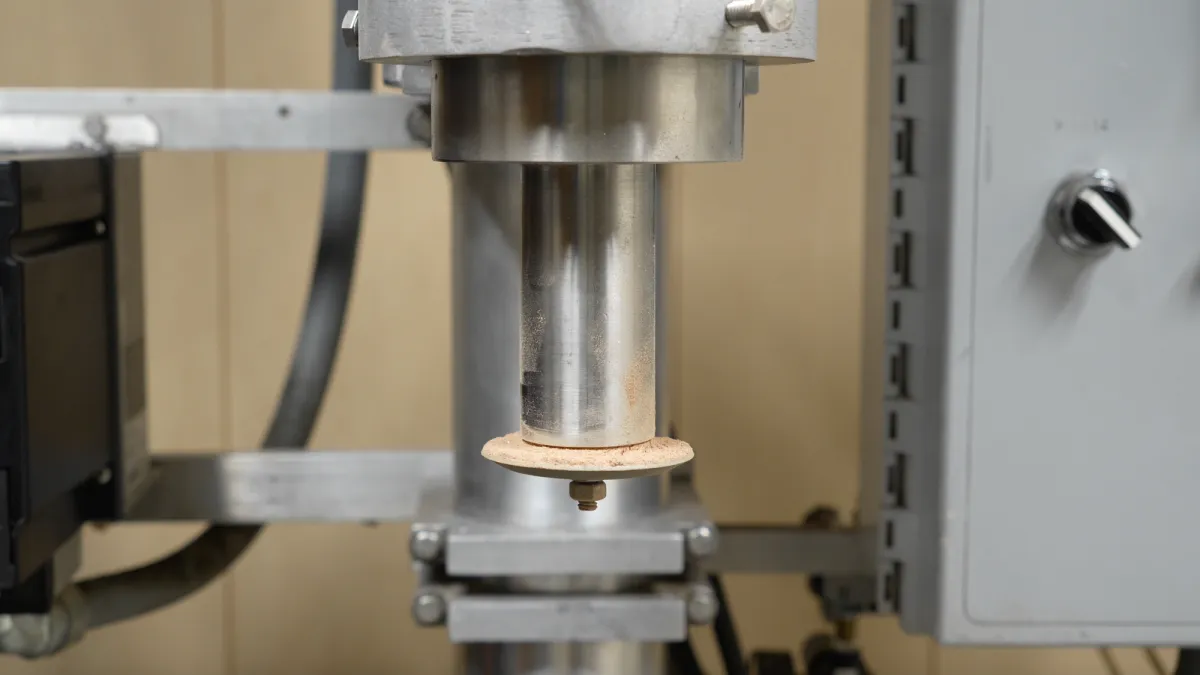

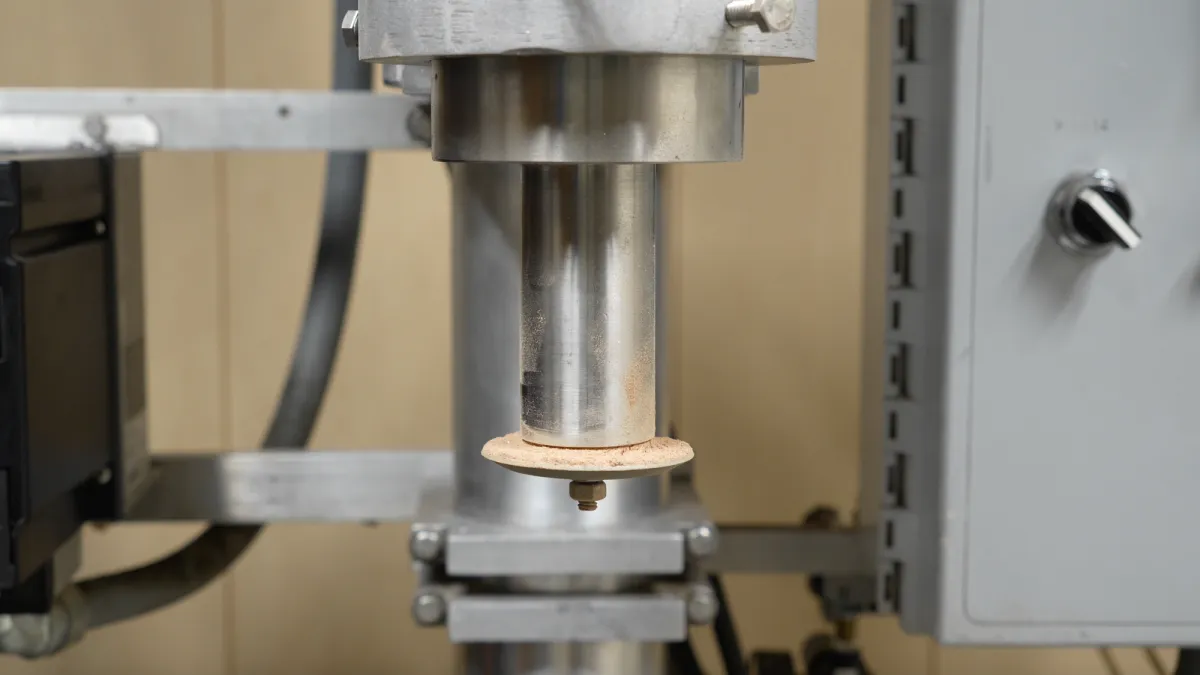

Auger alignment

Non free flow auger adjustment

Setup videos

Spinner plate adjustment

Auger alignment

Non free flow auger adjustment

Find repair tooling

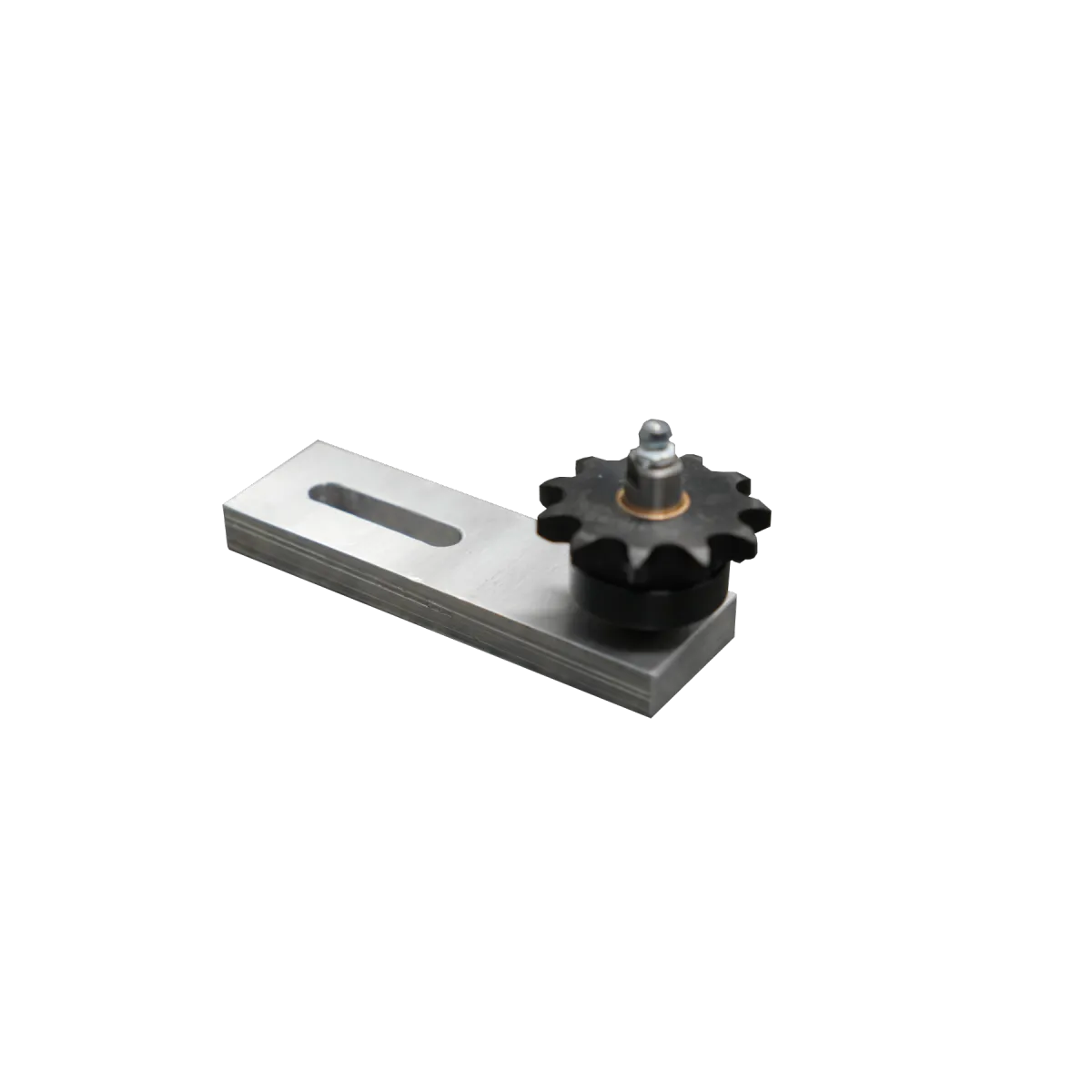

Auger alignment tool

Auger alignment

Hopper ring

Auger alignment

Disassembly & Repair Instruction

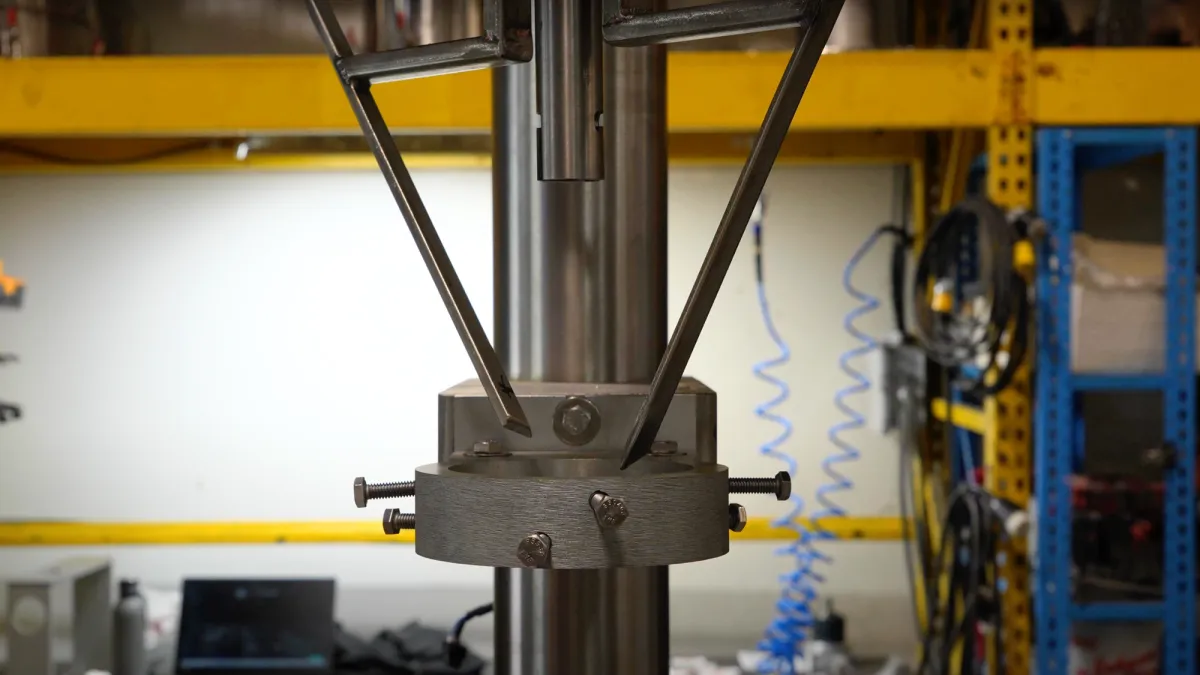

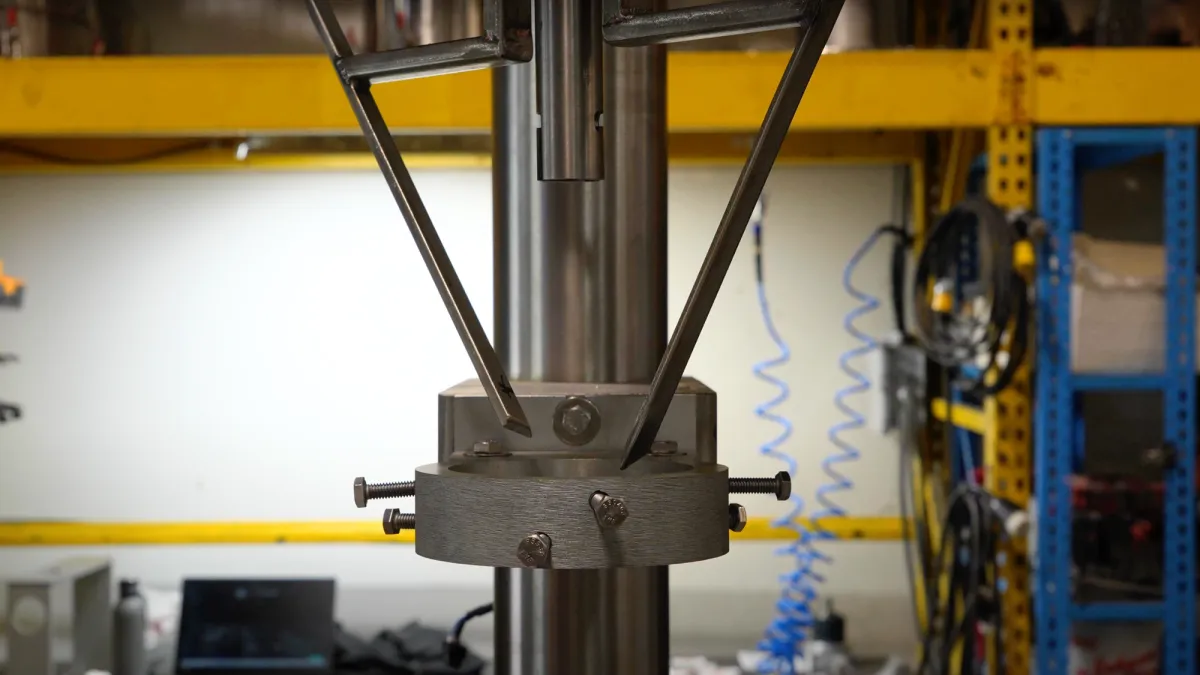

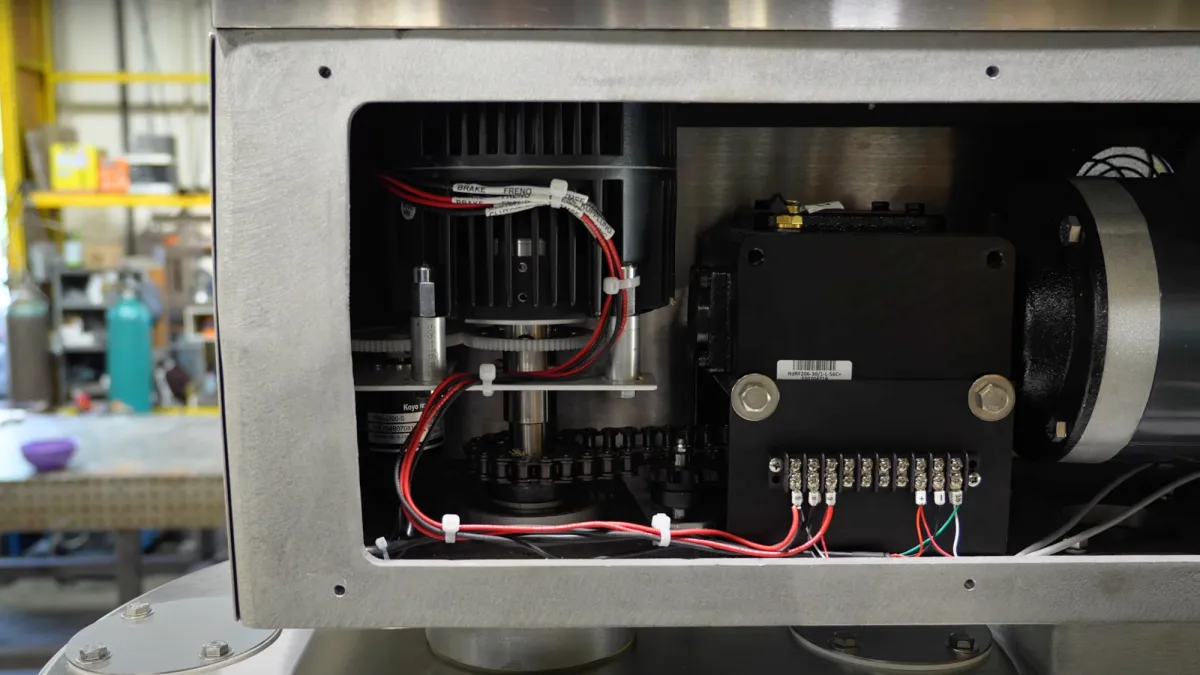

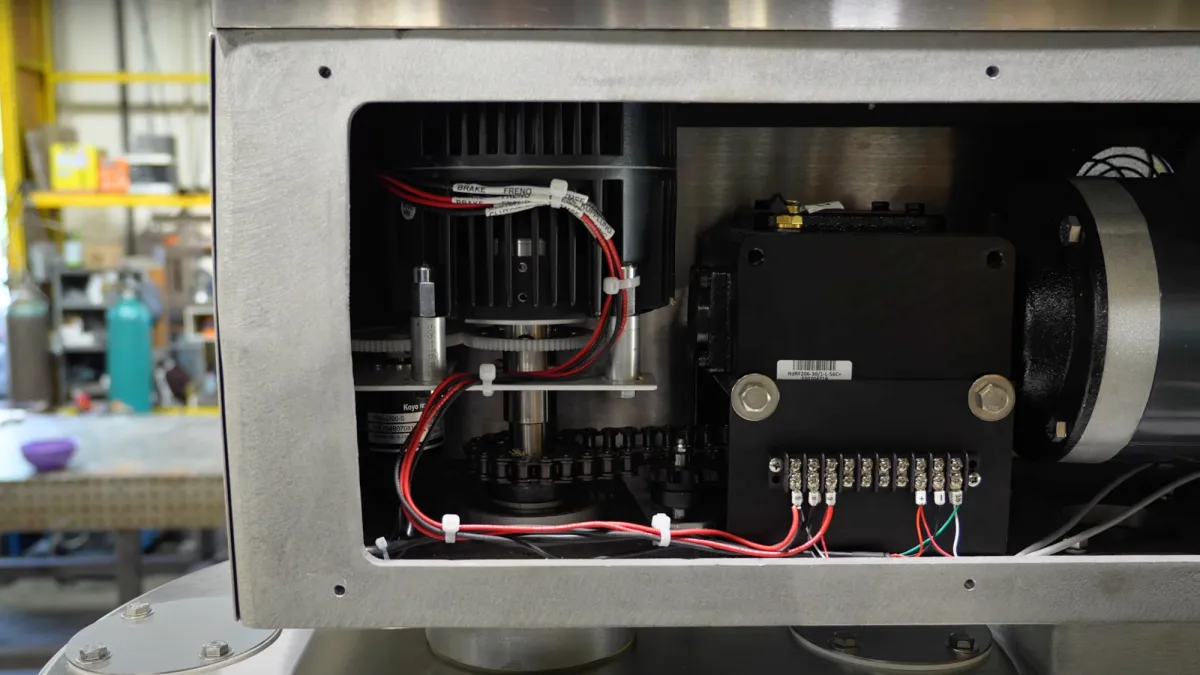

Slow speed bearing housing replacement

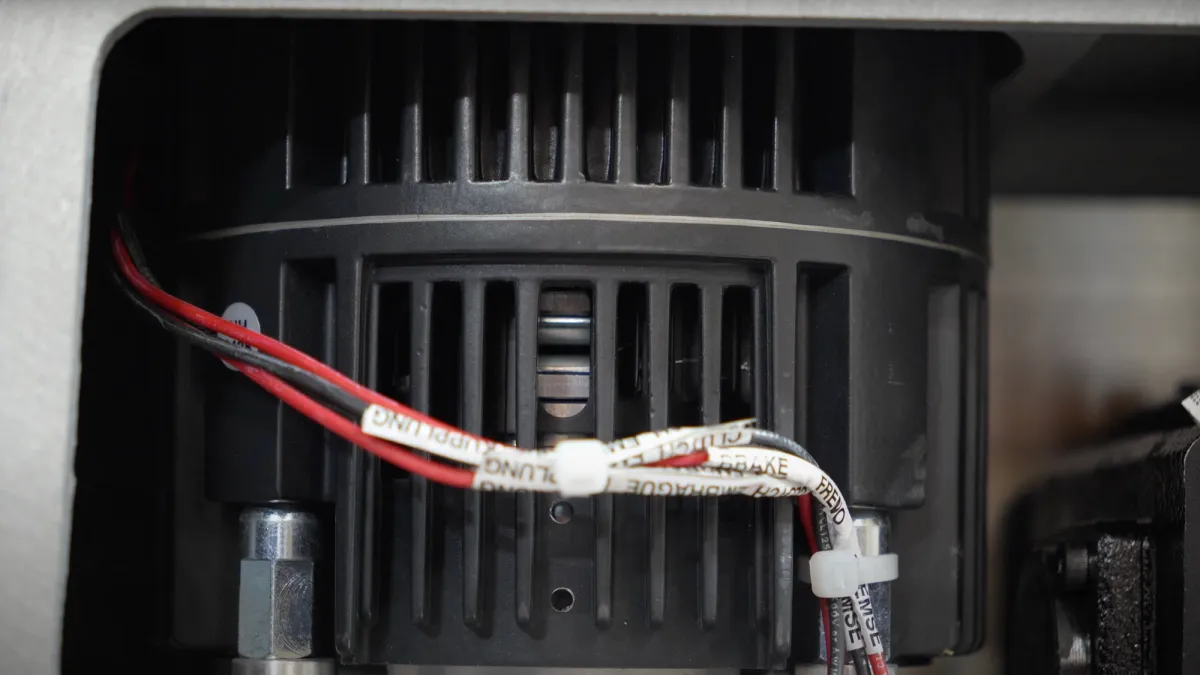

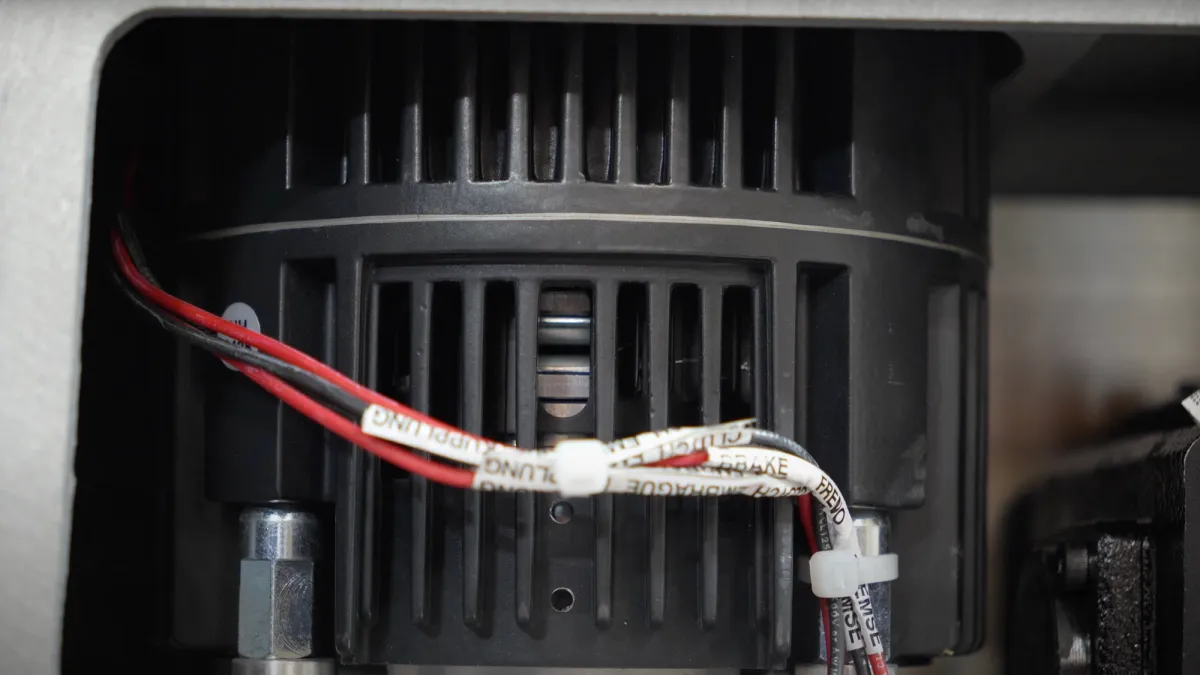

Clutch brake motor replacement

Non free flow auger filler disassembly

Fix your clutch brake armature plates

Disassembly Instruction

Slow speed bearing housing replacement

Clutch brake motor replacement

Non free flow auger filler disassembly

Fix your clutch brake armature plates

Find disassembly parts

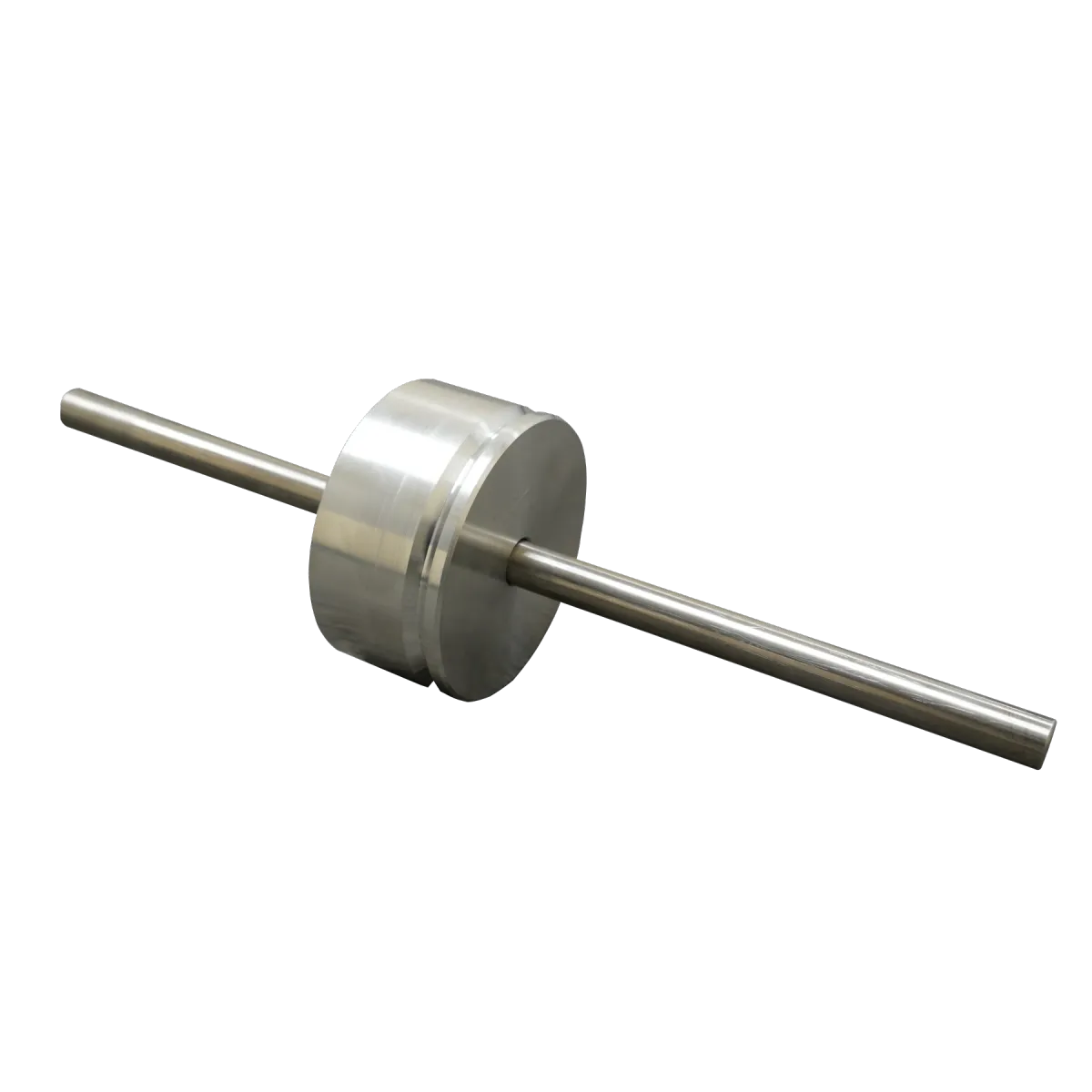

Slow speed bearing housing

Clutch brake motor

Prying irons

Idler assembly

PLC operation Instruction

Allen Bradley PLC instructions

Mitsubishi PLC instructions

PLC operation Instruction

Allen Bradley PLC instructions

Mitsubishi PLC instructions

Download PLC Manuals

Allen Bradley PLC Manual

Mitsubishi PLC Manual

Filler & product information

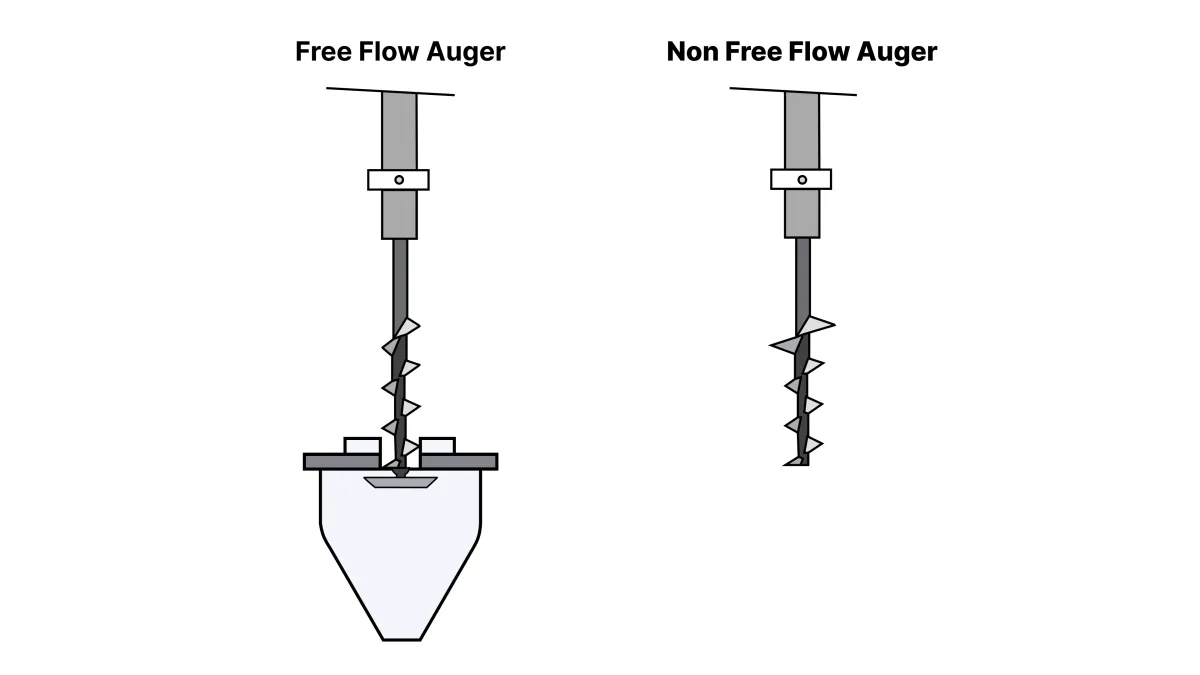

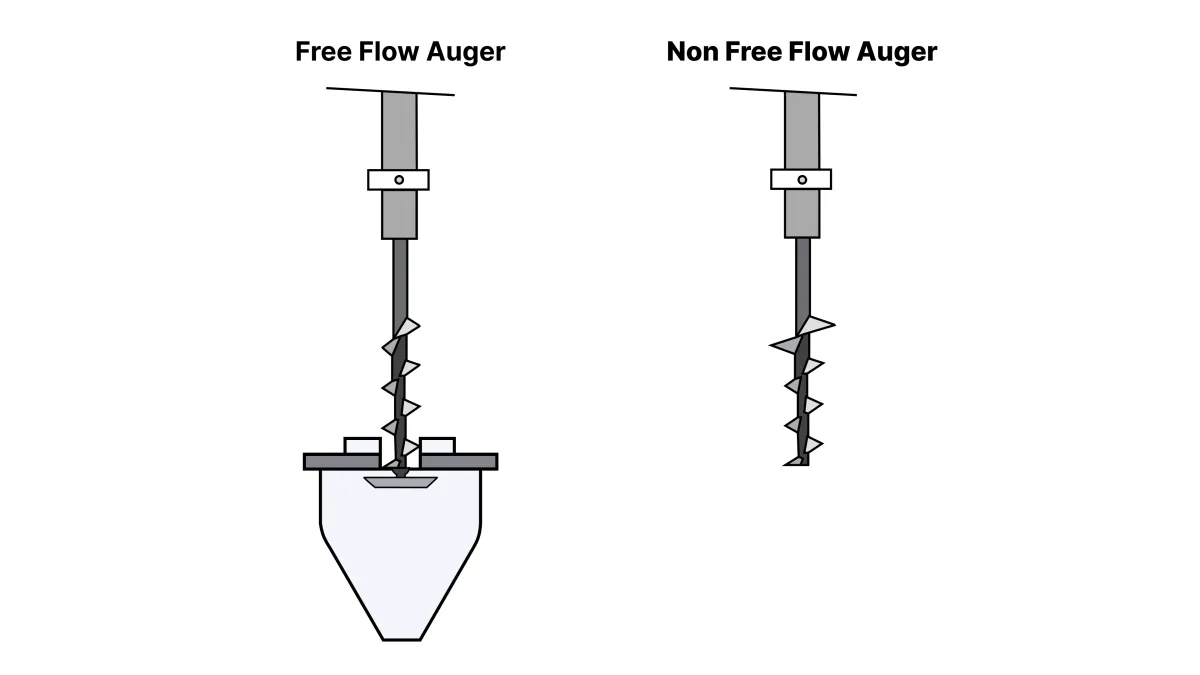

Determining free flow or non free flow

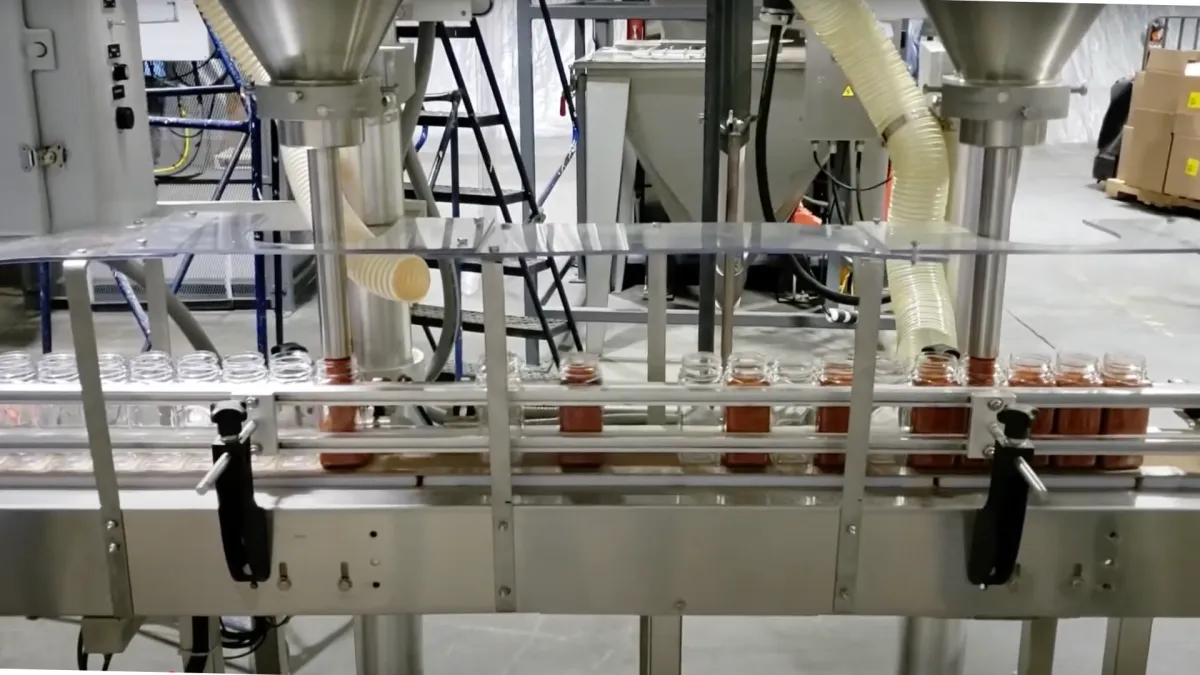

Fully automated bottling line components

Clutch brake or servo drive motor

Automation cost breakdown

Filler & product information

Determining free flow or non free flow

Fully automated bottling line

Clutch brake or servo drive motor

Automation cost breakdown

Contact

Hours: 9 AM - 5 PM

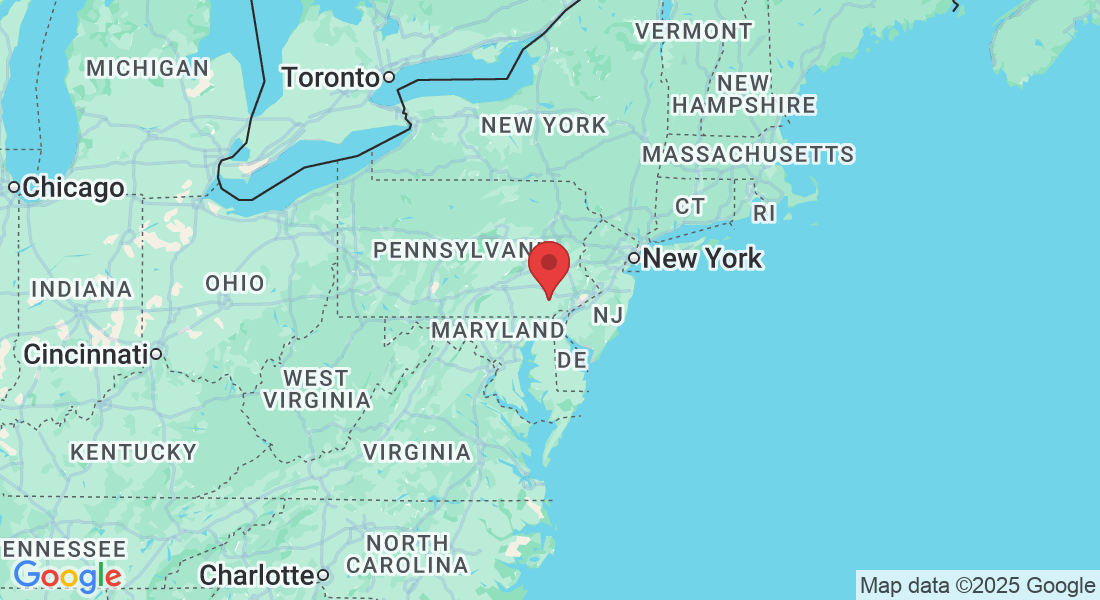

735 Fox Chase Rd # 111, Coatesville, PA 19320

(610) 466-1440

To purchase a machine, call (610) 466-1440 or email [email protected]

Image Fillers © 2025

Made in the United States